Normal pressure drying method for preparing melamine aerogel and fiber type clay reinforced melamine composite aerogel

A technology of composite aerogel and melamine gel, applied in the field of aerogel, can solve the problems of high cost, low strength, large-scale limitation of large-scale promotion and application, etc., and achieves the effect of short gel time and improved brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

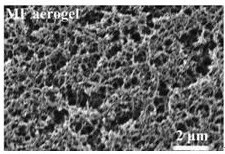

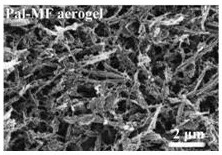

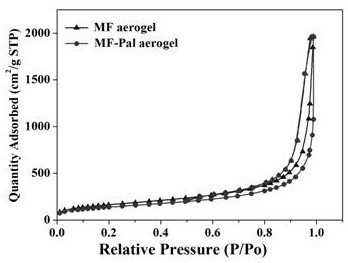

Image

Examples

Embodiment approach 1

[0025] This embodiment provides a method for preparing melamine airgel, specifically: take 0.3 g of melamine, add 5 mL of ethanol and stir to dissolve, then add 0.2 mL of hydrochloric acid and stir at a constant speed for 3 minutes at room temperature to obtain a melamine sol. The melamine sol was aged in a hydrothermal reactor at 100 °C for 20 hours to obtain a melamine gel. Soak the obtained melamine gel in ethanol at 50 °C, wash away the unreacted hydrochloric acid in the melamine gel, and finally dry the melamine gel in an oven at 50 °C under normal pressure to prepare melamine gas gel.

Embodiment approach 2

[0027] This embodiment provides a method for preparing melamine airgel, specifically: take 0.3 g of melamine and add 6.0 mL of isopropanol to stir and dissolve, then add 0.2 mL of hydrochloric acid and stir at a constant speed for 3 minutes at room temperature to obtain melamine sol . The melamine sol was aged in a hydrothermal reactor at 80 °C for 20 hours to obtain a melamine gel. The obtained melamine gel was soaked in isopropanol at 60 °C to wash off the unreacted hydrochloric acid in the melamine gel, and finally the melamine gel was dried in an oven at 60 °C under normal pressure to obtain a dense Amine airgel.

Embodiment approach 3

[0029] This embodiment provides a method for preparing melamine airgel, specifically: take 0.2 g of melamine and add 6.0 mL of isopropanol to stir and dissolve, then add 0.2 mL of hydrochloric acid and stir at a constant speed for 3 minutes at room temperature to obtain melamine sol . The melamine sol was aged in a hydrothermal reactor at 160 °C for 8 h to obtain a melamine gel. Soak the obtained melamine gel in ethanol at 50 °C to wash off the unreacted hydrochloric acid in the melamine gel, and finally dry the melamine gel in an oven at 45 °C under normal pressure to obtain melamine gas gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com