Real stone paint coating and preparation method thereof

A technology of real stone paint and coating, applied in the direction of coating, etc., can solve the problems of poor comprehensive performance of real stone paint coating, water resistance, alkali resistance, impact resistance, coating temperature change resistance and artificial aging resistance, etc. Improved artificial aging, short drying time, and good overall protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

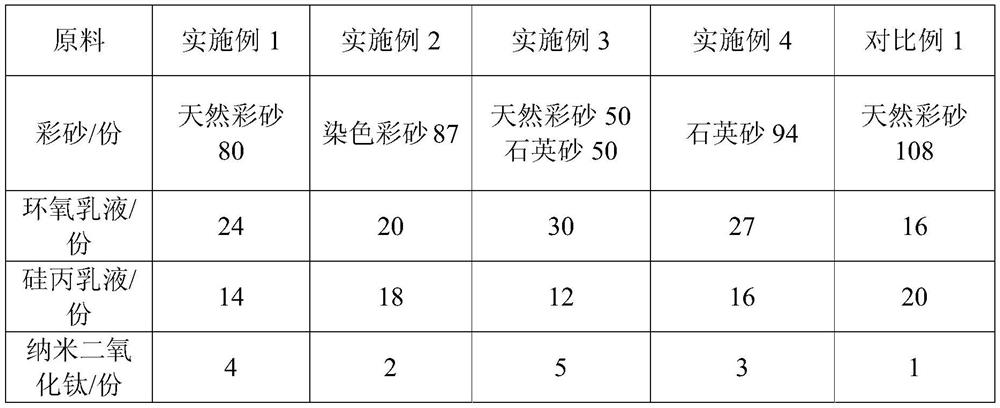

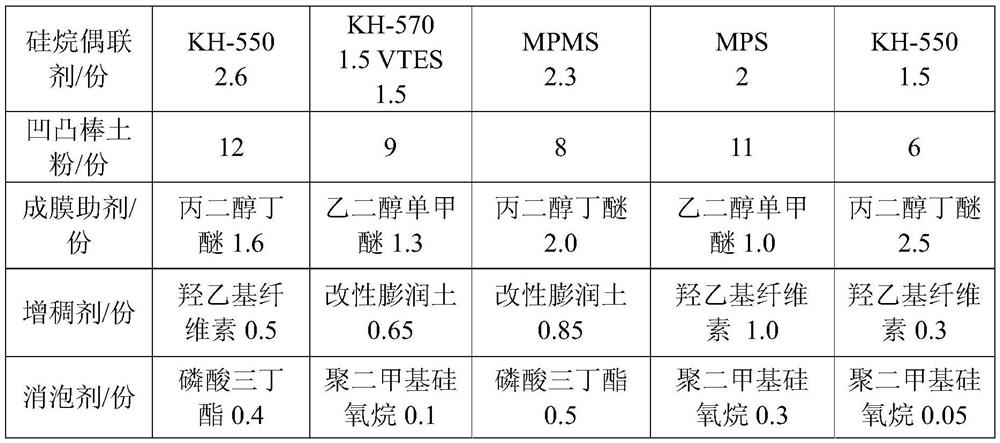

[0030] The real stone paint coating designed in this embodiment includes the following raw materials in parts by mass: 80 parts of natural colored sand, 24 parts of epoxy emulsion, 14 parts of silicon acrylic emulsion, 4 parts of nano titanium dioxide, 2.6 parts of KH-550, concave-convex 12 parts of clay powder, 1.6 parts of propylene glycol butyl ether, 0.5 parts of hydroxyethyl cellulose and 0.4 parts of tributyl phosphate.

[0031] The present embodiment also provides the preparation method of the above-mentioned genuine stone paint coating, comprising the following steps: S1. In order by mass parts, epoxy emulsion, silicon acrylic emulsion, nano-titanium dioxide, KH-550, attapulgite powder, propylene glycol butyl ether , hydroxyethyl cellulose and tributyl phosphate are added to the stirring reaction kettle, and stirred evenly; S2. Add natural colored sand and stir, and after stirring evenly, a real stone paint coating is obtained.

Embodiment 2

[0033] The real stone paint coating designed in this embodiment includes the following raw materials in parts by mass: 87 parts of dyed colored sand, 20 parts of epoxy emulsion, 18 parts of silicon acrylic emulsion, 2 parts of nano titanium dioxide, 1.5 parts of KH-570, VTES 1.5 parts, 9 parts of attapulgite powder, 1.3 parts of ethylene glycol monomethyl ether, 0.65 parts of modified bentonite and 0.1 part of polydimethylsiloxane.

[0034] The present embodiment also provides the preparation method of the above-mentioned real stone paint coating, which includes the following steps: S1. In order by mass parts, epoxy emulsion, silicon acrylic emulsion, nano-titanium dioxide, KH-570, VTES, attapulgite powder, B Add glycol monomethyl ether, modified bentonite and polydimethylsiloxane into the stirring reaction kettle, and stir evenly; S2. Add dyed colored sand and stir, and get the real stone paint after stirring evenly.

Embodiment 3

[0036]The real stone paint coating designed in this embodiment includes the following raw materials in parts by mass: 50 parts of natural colored sand, 50 parts of quartz sand, 30 parts of epoxy emulsion, 12 parts of silicon acrylic emulsion, 5 parts of nano-titanium dioxide, MPMS 2.3 8 parts of attapulgite powder, 2.0 parts of propylene glycol butyl ether, 0.85 parts of modified bentonite and 0.5 parts of tributyl phosphate.

[0037] The present embodiment also provides the preparation method of the above-mentioned real stone paint coating, which includes the following steps: S1. In order by mass parts, epoxy emulsion, silicon acrylic emulsion, nano-titanium dioxide, MPMS, attapulgite powder, propylene glycol butyl ether, modified Stir bentonite and tributyl phosphate into the stirring reaction kettle, and stir evenly; S2. Add natural colored sand and quartz sand and stir, and get real stone paint after stirring evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com