Bacillus cereus capable of producing cellulase and xylanase at low temperature

A Bacillus cereus, cellulase technology, applied in the field of microbial engineering, can solve the problems of low enzyme production enzyme activity, little research on Bacillus cereus enzyme production, discounted enzyme activity effect, etc., and achieves high enzyme activity, excellent pH resistance. The effect of acceptability and good enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

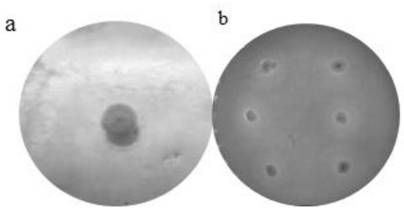

[0021] Embodiment 1: Screening and identification of the original bacterial strain TK-1

[0022] (1) Isolation of strains

[0023] (1) Collect 5g of soil samples in the forest area of Changbai Mountain Nature Reserve, dissolve them in 100mL of prepared saline solution, shake and cultivate at 10°C and 180rpm for 2-4h, and the saline solution is 0.006mM FeSO 4 ·7H 2 O; 0.01 mM CaCO 3 ·7H 2 O; 0.08mM MgSO 4 ·7H 2 O; 0.07mM MnSO 4 ·7H 2 O and 0.006mM ZnSO 4 ·7H 2 O composition.

[0024] (2) Dilute 1mL of the mixed soil sample salt solution with different gradients (10-2, 10-3, 10-4), take 200ul of the diluted solution and spread it on the R2a solid plate, and place it in a constant temperature culture at 10°C Cultivate statically in the box for 7-10 days. The fixed plate contains 0.5g yeast extract powder, 0.5g peptone, 0.5g casein hydrolyzate, 0.5g glucose, 0.5g soluble starch, 0.3g potassium dihydrogen phosphate, 0.024g anhydrous Magnesium sulfate, 0.3g sodium pyruv...

Embodiment 2

[0041] Embodiment 2: original bacterial strain TK-1 mutagenesis treatment

[0042] Using ARTP mutagenesis, the mutagenesis steps are as follows:

[0043]The power is 100W, the mutagenic working gas is helium, the gas flow rate is 12s / m, and the distance is 3mm to irradiate for mutagenesis. After diluting the mutagenized bacterial suspension, take 100 μL of the diluted solution and spread it on a PDA plate. Cultured in an incubator. Take 1 mL of the bacterial solution cultured to the logarithmic phase (OD600 between 0.6 and 0.8) in a 1.5-ml centrifuge tube, centrifuge at 10,000 rpm for 2 minutes, discard the supernatant, and resuspend the bacteria twice with normal saline to obtain a cell suspension. Dilute to adjust cell number at 10 6 -10 8 pieces / ml.

[0044] Take 10uL of the cell suspension and evenly spread it on the surface of the metal slide (sterilized), and adjust the parameters of the ARTP instrument:

[0045] The treated slides were transferred to a centrifuge t...

Embodiment 3

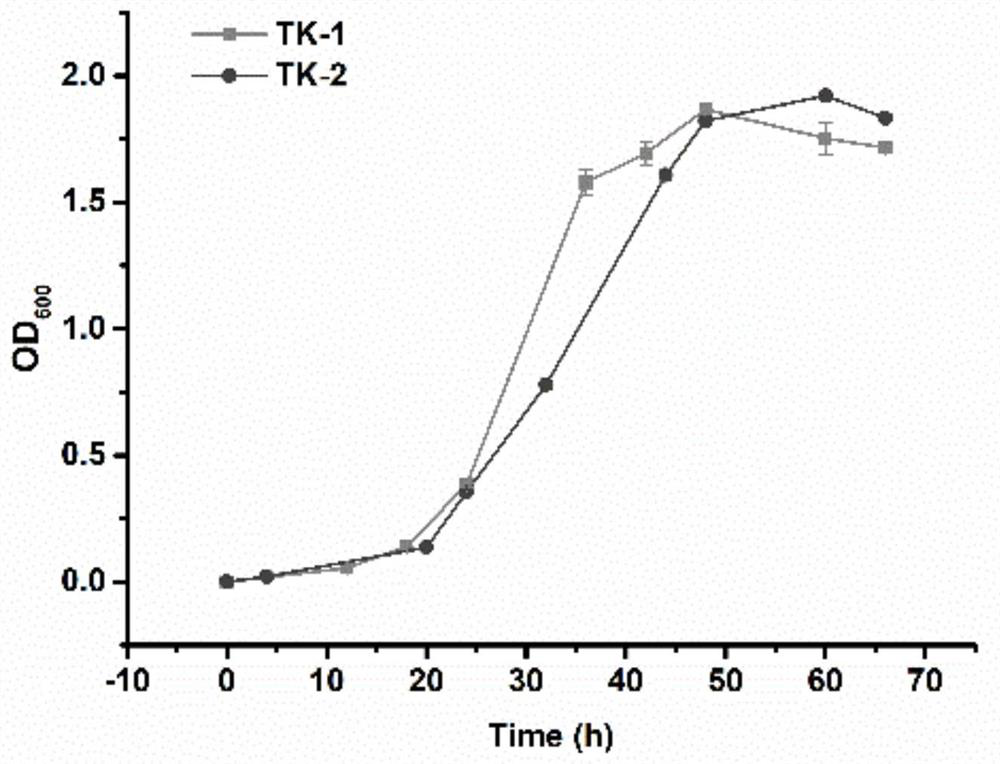

[0047] Embodiment 3: the growth and enzyme production analysis of Bacillus cereus TK-2

[0048] (1) Analysis of growth characteristics of Bacillus cereus TK-1 and TK-2

[0049] (1) The bacterial strain TK1 and the mutant strain TK-2 that grow well at low temperature and produce cellulase and xylanase obtained by mutagenesis are respectively inoculated in LB liquid medium, at a rotating speed of 180rpm, different temperatures (10 , 15, 20, 25, 37°C) for shaking culture, sampling at fixed points, and measuring the OD of the bacterial solution 600 value.

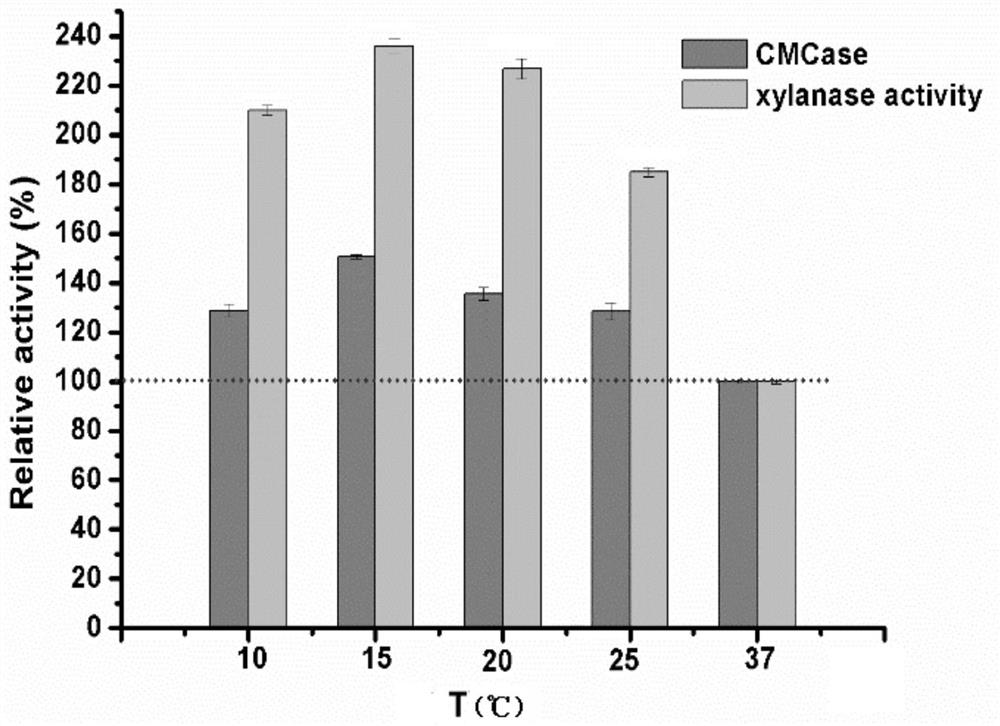

[0050] (2) Analysis of enzyme production characteristics of Bacillus cereus TK-1 and TK-2

[0051] (1) Inoculate the logarithmic phase bacterial liquid in the fermentation enzyme production medium (ammonium sulfate 4g / l, dipotassium hydrogen phosphate 2 g / L, magnesium sulfate heptahydrate 0.1g / L, yeast extract 10g / L, peptone 1g / L, xylan / CMC-Na 1.5%), the inoculum volume was 200uL, the rotation speed was 180rpm, and shaking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com