Production process of ultraviolet-proof chinlon/spandex air-coated yarn

An air-coated silk, UV protection technology, applied in the manufacture of rayon, filament/thread forming, single-component polyamide rayon, etc. Achieve enhanced UV protection and soft comfort, prevent breakage, reduce friction damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

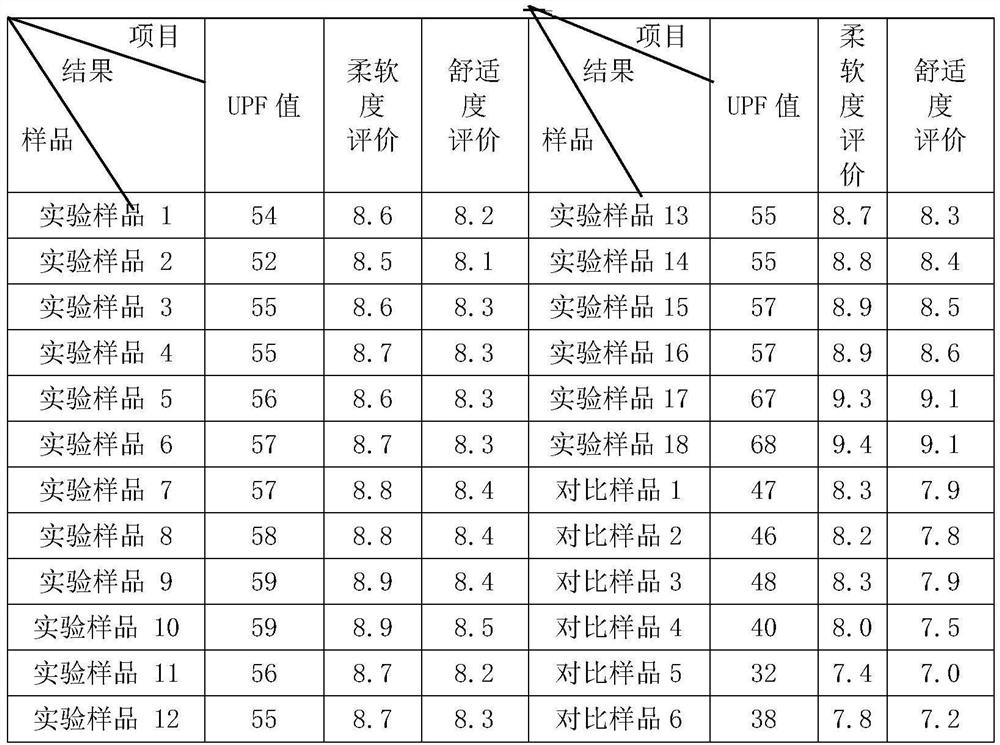

Examples

Embodiment 1

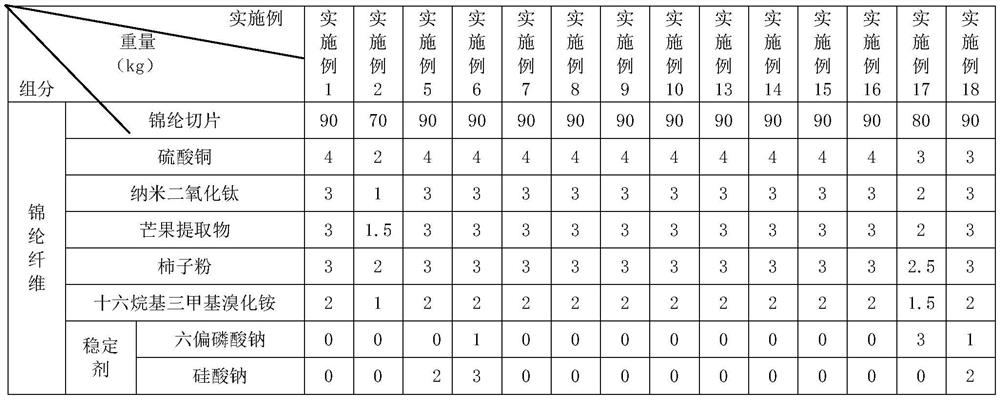

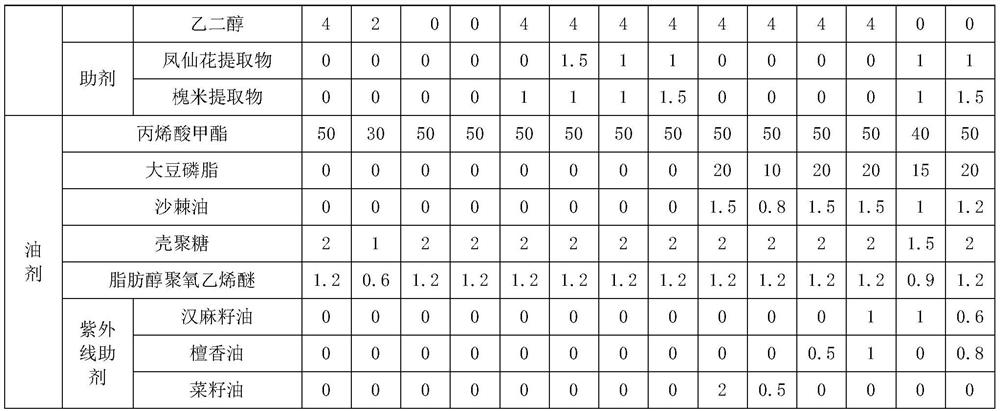

[0050] A kind of production technology of anti-ultraviolet bronzing ammonia air-coated silk, the concrete component that comprises and weight are as shown in table 2, are made by following steps:

[0051] S1: Methyl acrylate and fatty alcohol polyoxyethylene ether are mixed and stirred, the stirring speed is 700r / min, after stirring evenly, chitosan is added to mix and stir, the stirring speed is 800r / min, and the oil agent is obtained after stirring;

[0052] S2: Mix and stir copper sulfate, nano-titanium dioxide, mango extract, persimmon powder, cetyltrimethylammonium bromide, and stabilizer at a stirring speed of 1000r / min. After stirring evenly, add nylon slices, and then extrude High-temperature melting is carried out in the extruder. The screw extruder is divided into six temperature zones. The temperature of the high-temperature melting zone is 270°C-300°C-310°C-300°C-290°C-285°C. The speed of the screw extruder is 120r / min, pressure 65MPa, after distribution, spinning,...

Embodiment 2

[0055]Embodiment 2: a kind of production technology of the bronzing ammonia air-coated silk of anti-ultraviolet, and the difference of embodiment 1 is, concrete component and weight are different, and the concrete component that comprises and weight are as shown in table 2.

Embodiment 3

[0056] Embodiment 3: a kind of production technology of anti-ultraviolet nylon air-covered silk, the difference with embodiment 1 is that the weight ratio of nylon fiber and spandex fiber is 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com