Ammonia gas sensor based on perovskite quantum dots and ammonia gas quantitative detection method

An ammonia gas sensor, perovskite technology, applied in chemical instruments and methods, nanotechnology for sensing, instruments, etc., can solve the problems of poor selectivity and high working temperature of gas sensors, achieve excellent performance, overcome ultra-high Working temperature, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] (1) First cut the quartz glass into 1cm×1cm with a glass cutting machine, wipe the surface stains with an acetone cotton ball, then place the quartz substrate in isopropanol-acetone-water-acetone-isopropanol for 15 minutes, and then Dry in an oven at 70°C for later use.

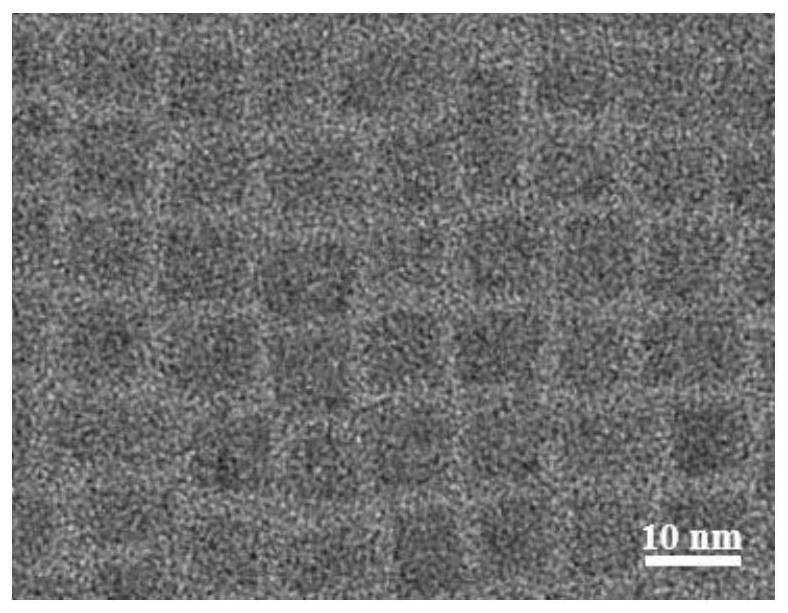

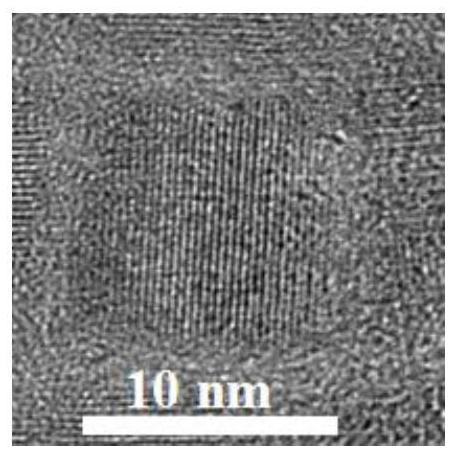

[0118] (2) Perovskite quantum dots were synthesized by hot injection method. Will Cs 2 CO 3 (0.814g) was added into a 100mL three-neck flask together with octadecene, ODE (30mL) and oleic acid, OA (2.5mL), dried at 120°C for 1h, and then 2 under heating to 160°C until all Cs 2 CO 3 The cesium oleate solution was reacted with OA, and the cesium oleate solution was kept at 160° C. before injection to avoid solidification. Mix 24.0mL ODE, 10mL OA and PbBr 2 (1.38 g) was charged into a 250 mL flask, evacuated at 120°C for 30 minutes and heated to 180°C under nitrogen flow. Inject 8 mL of cesium oleate solution (0.08 moL in ODE) rapidly. Within 5 s, the reaction mixture was cooled using an ice-water...

Embodiment 2

[0124] (1) First cut the quartz glass into 1cm×1cm with a glass cutting machine, wipe the surface stains with an acetone cotton ball, and then place the quartz substrate in isopropanol-acetone-water-acetone-isopropanol for 15 minutes, and then Dry in an oven at 70°C for later use.

[0125] (2) Perovskite quantum dots were synthesized by hot injection method. Will Cs 2 CO 3 (0.814g) was added into a 100mL three-neck flask together with octadecene, ODE (30mL) and oleic acid, OA (2.5mL), dried at 120°C for 1h, and then 2 under heating to 160°C until all Cs 2 CO 3 The cesium oleate solution was reacted with OA, and the cesium oleate solution was kept at 160° C. before injection to avoid solidification. Mix 24.0mL ODE, 10mL OA and PbBr 2 (1.38 g) was charged into a 250 mL flask, evacuated at 120°C for 30 minutes and heated to 180°C under nitrogen flow. Inject 8 mL of cesium oleate solution (0.08 moL in ODE) rapidly. Within 5 s, the reaction mixture was cooled using an ice-w...

Embodiment 3

[0130] (1) First cut the quartz glass into 1cm×1cm with a glass cutting machine, wipe the surface stains with an acetone cotton ball, and then place the quartz substrate in isopropanol-acetone-water-acetone-isopropanol for 15 minutes, and then Dry in an oven at 70°C for later use.

[0131] (2) Perovskite quantum dots were synthesized by hot injection method. Will Cs 2 CO 3 (0.814g) was added into a 100mL three-neck flask together with octadecene, ODE (30mL) and oleic acid, OA (2.5mL), dried at 120°C for 1h, and then 2 under heating to 160°C until all Cs 2 CO 3 The cesium oleate solution was reacted with OA, and the cesium oleate solution was kept at 160° C. before injection to avoid solidification. Mix 24.0mL ODE, 10mL OA and PbBr 2 (1.38 g) was charged into a 250 mL flask, evacuated at 120°C for 30 minutes and heated to 180°C under nitrogen flow. Inject 8 mL of cesium oleate solution (0.08 moL in ODE) rapidly. Within 5 s, the reaction mixture was cooled using an ice-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com