Filtering material and application thereof in preparation of high-purity guanidine carbonate

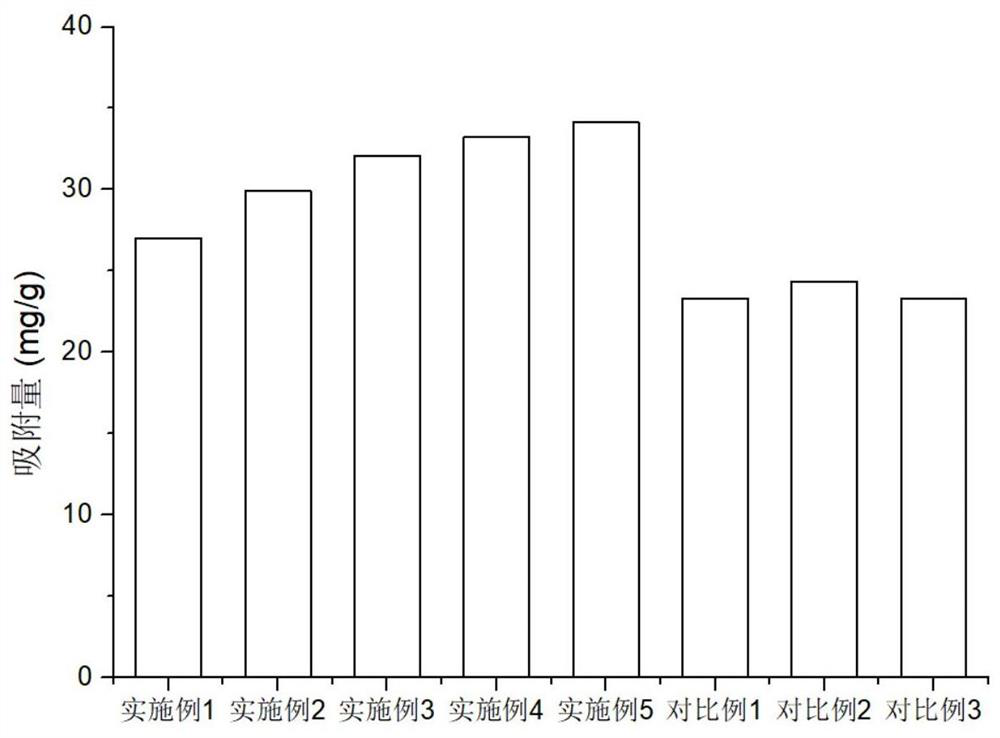

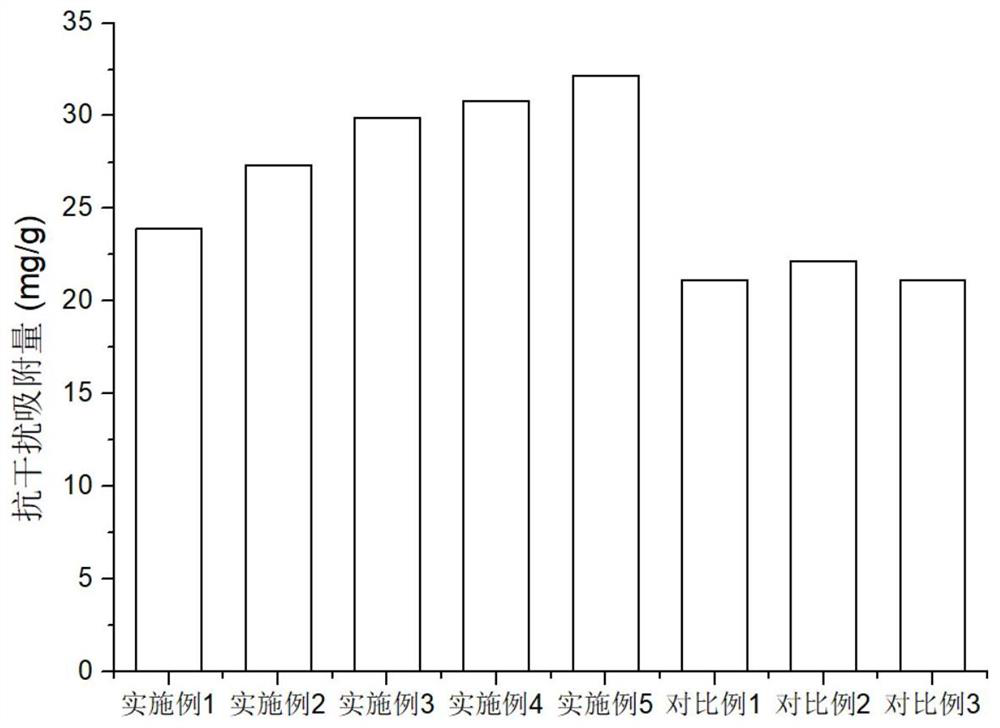

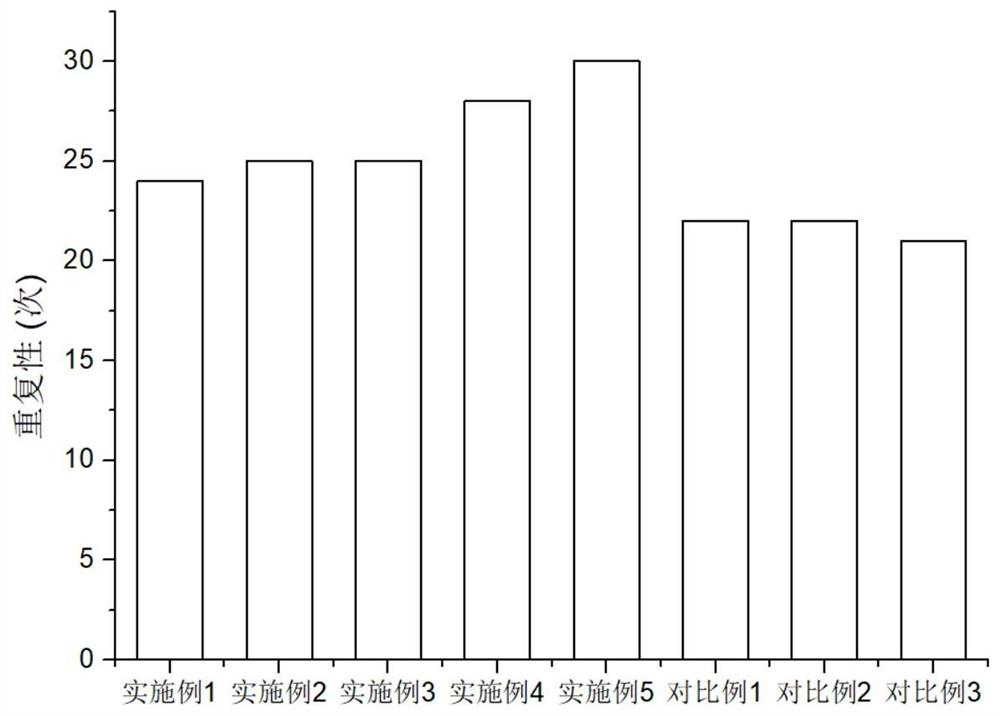

A technology of multi-walled carbon nanotubes and polymers, applied in the field of filter materials, can solve problems such as difficult to completely remove and obtain high-purity guanidine carbonate, and achieve strong anti-interference ability, good adsorption performance, and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for preparing magnetic molecularly imprinted polymers,

[0055]Modified multi-walled carbon nanotubes: Sonicate the multi-walled carbon nanotubes in an acidic solution for 2 hours, separate them, rinse until neutral, dry, add toluene and sonicate for 1 hour, add acrylic acid at a temperature of 60°C, and then add AIBN, Reacted for 9 hours, separated by suction filtration, washed with deionized water, and dried to obtain modified multi-walled carbon nanotubes. The acidic solution is a mixed solution of sulfuric acid and nitric acid, and the mixing ratio of sulfuric acid and nitric acid in the acidic solution is a mass ratio of 1:0.3; the amount of multi-walled carbon nanotubes is 0.3wt% of the acidic solution; the multi-walled carbon after acid solution treatment The addition amount of nanotube is 0.2wt% of toluene; the addition amount of acrylic acid is 1.5wt% of toluene; the addition amount of AIBN is 1wt% of acrylic acid.

[0056] Preparation of modified cou...

Embodiment 2

[0061] Compared with Example 1, the present invention differs only in that in the preparation of modified multi-walled carbon nanotubes, the amount of acrylic acid added is 2.8wt% of that of toluene, in the preparation of modified halloysite nanotubes, the modified coupling The addition amount of agent is 23wt% of ethanol solution.

Embodiment 3

[0063] Compared with Example 1, the present invention is only different in that in the preparation of modified multi-walled carbon nanotubes, the amount of acrylic acid added is 4.2wt% of that of toluene, and in the preparation of modified halloysite nanotubes, the modified coupling The addition amount of agent is 34wt% of ethanol solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com