Composite gas-sensitive material and preparation method thereof, and ethanol gas sensor and preparation method thereof

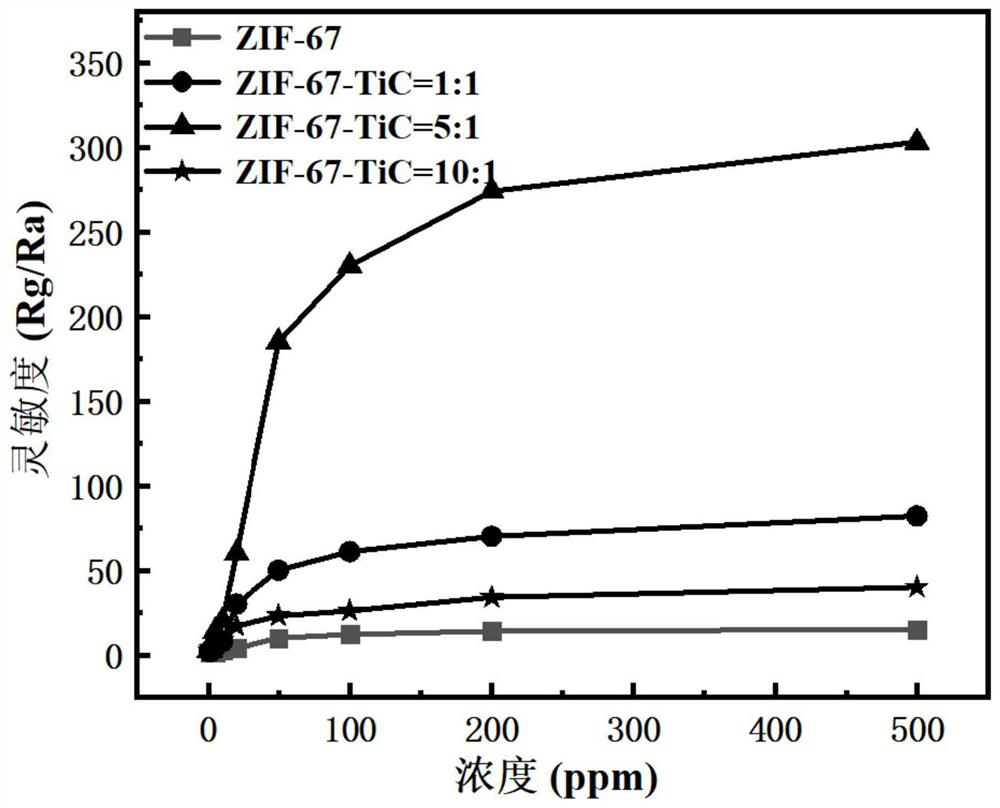

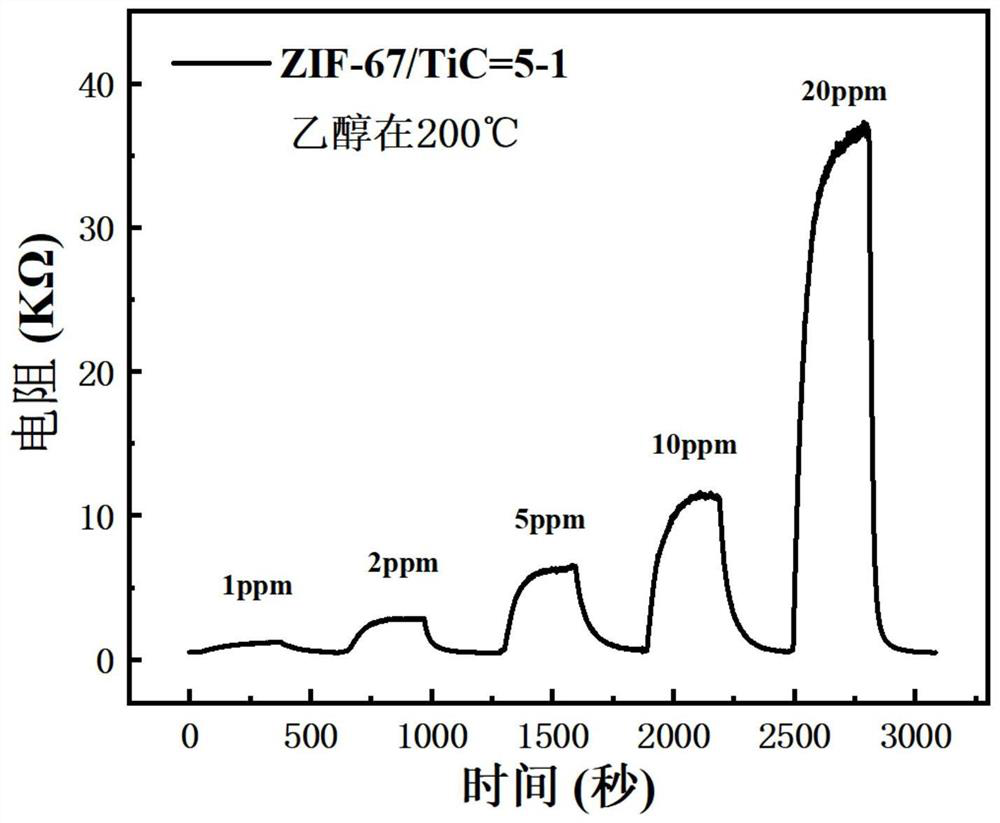

A gas sensor and gas-sensitive material technology, which is applied in the fields of analyzing materials, material resistance, and material analysis by electromagnetic means. It can solve the problems of low selectivity, poor sensitivity and stability, and inability to meet the needs of gas sensors. The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

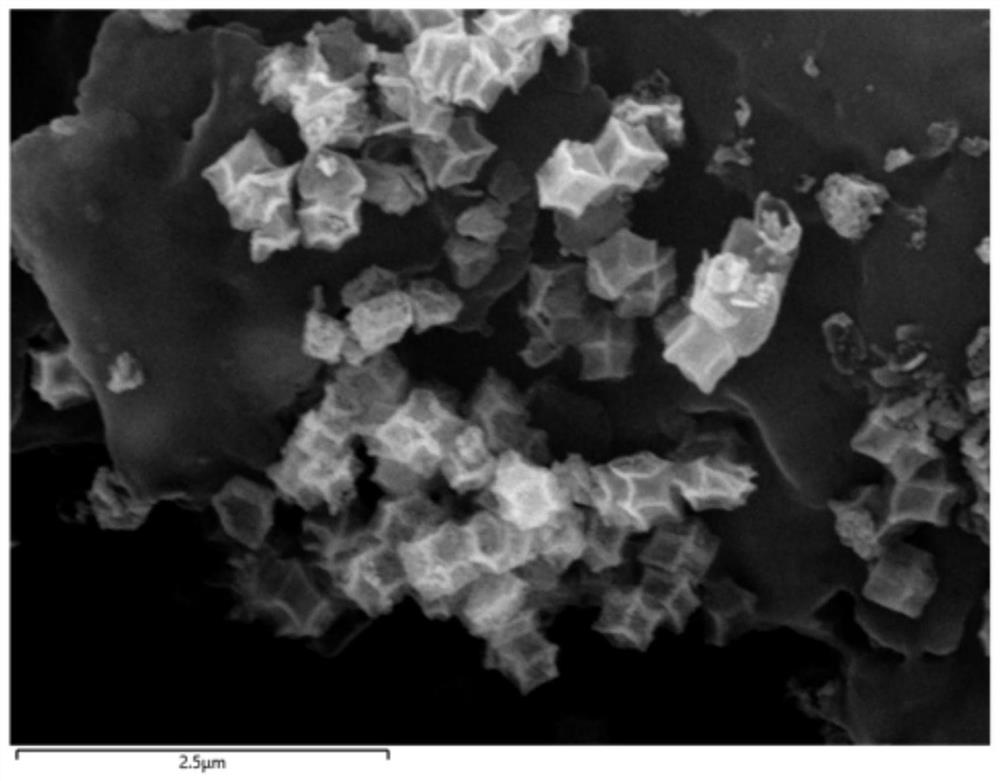

[0033] The preparation method of the metal-organic framework derivative-trititanium dicarbide composite gas-sensing material comprises the following steps:

[0034] S1, stirring and dissolving a certain amount of metal salt hydrate in a solvent to obtain a mixed solution A;

[0035] The mass ratio of the metal salt hydrate to the solvent is 1:(50-150).

[0036] S2. Adding a metal-organic framework precursor to the above mixed solution A to obtain a mixed solution B;

[0037] The mass ratio of the metal-organic framework precursor to the solvent is 1: (100-200).

[0038] S3. Add a certain amount of trititanium dicarbide to the above mixed solution B, and ultrasonically obtain the mixed solution C for 1 hour, and let it stand for precipitation at room temperature for 24 hours;

[0039] The mass ratio of the trititanium dicarbide to the metal-organic framework precursor is 1: (1-100).

[0040] S4. Take out the sediment at the bottom and centrifuge twice in ethanol and deionize...

Embodiment 1

[0054] A method for preparing a metal-organic framework-derived tricobalt tetroxide-trititanium dicarbide composite gas-sensing material, comprising the following steps:

[0055] S1. Stir and dissolve cobalt nitrate hexahydrate in methanol solution to obtain mixed solution A. The mass ratio of cobalt nitrate hexahydrate to methanol is 1:50.

[0056] S2. Add 2-methylimidazole to mixed solution A to obtain mixed solution B. The mass ratio of 2-methylimidazole to methanol is 1:100.

[0057] S3. Add a certain amount of trititanium dicarbide to the mixed solution B, sonicate for 1 hour to obtain the mixed solution C, and let it stand for precipitation at room temperature for 24 hours. The mass ratio of trititanium dicarbide to cobalt nitrate hexahydrate is 1:1.

[0058] S4. After pouring out the supernatant, centrifuge the bottom sediment in ethanol and deionized water twice respectively, and dry the sediment at 60°C for 24 hours to obtain a powder;

[0059] S5. Calcining the obta...

Embodiment 2

[0062] A method for preparing a metal-organic framework-derived zinc oxide-trititanium carbide composite gas-sensing material, comprising the following steps:

[0063] S1. Stir and dissolve zinc nitrate hexahydrate in methanol solution to obtain mixed solution A. The mass ratio of cobalt nitrate hexahydrate to methanol is 1:100.

[0064] S2. Add 2-methylimidazole to mixed solution A to obtain mixed solution B. The mass ratio of 2-methylimidazole to methanol is 1:150.

[0065] S3. Add a certain amount of trititanium dicarbide to the mixed solution B, sonicate for 1 hour to obtain the mixed solution C, and let it stand for precipitation at room temperature for 24 hours. The mass ratio of trititanium dicarbide to zinc nitrate hexahydrate is 1:40.

[0066] S4. After pouring out the supernatant, centrifuge the bottom sediment in ethanol and deionized water twice respectively, and dry the sediment at 60°C for 24 hours to obtain a powder;

[0067] S5. Calcining the obtained powder i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com