Preparation method of charcoal-roasted oat milk containing polypeptide

A technology of oat and charcoal burning, which is applied in the direction of dairy products, multi-step food processing, and the function of food ingredients, etc. It can solve the problems that macromolecular proteins and starches are difficult to be utilized by the human body, so as to improve the coordination of smell, reduce production costs, The effect of improving flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

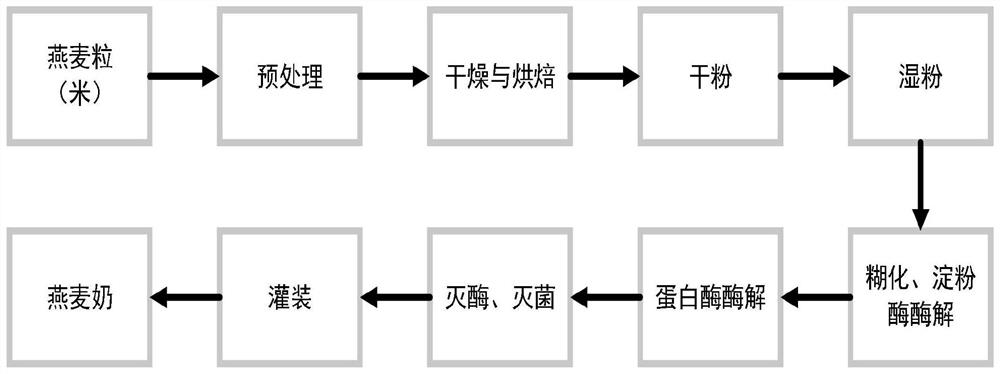

[0034] combine figure 1 Shown, the preparation method of charcoal burning oat milk, concrete steps are as follows:

[0035] a. Take about 15kg of oats (the oats imported from Australia imported from Ximai Oats Co., Ltd.) and wash them with 3 times the volume of water for 3 times, and drain the water with a 40-mesh sieve.

[0036] b. The oats obtained in step a were baked in a drum drying oven at 160° C. for 40 minutes, and the chroma was 237 EBC.

[0037] c. The oats obtained in step b are dry ground to 100 mesh in a universal pulverizer. Weigh 12 kg of oat flour, slowly add it to the colloid mill for wet pulverization and defibrination.

[0038] d. Transfer the oat pulp obtained in step c to an enzymatic hydrolysis tank, set the volume to 50 kg, add 25 g of high-temperature-resistant α-amylase, heat up to 70 degrees, and maintain for 40 minutes to gelatinize and liquefy the starch. Take a sample to measure the DE value of 22%.

[0039] e. Cool the enzymolysis tank to 53°C,...

Embodiment 2

[0047] combine figure 1 Shown, the preparation method of charcoal burning oat milk, concrete steps are as follows:

[0048] a. Take about 50kg of oats (the oats imported from Australia imported from Ximai Oats Co., Ltd.) and wash them twice with 5 times the volume of water, and drain the water with a 40-mesh sieve.

[0049] b. The oats obtained in step a were baked in a drum drying oven at 180° C. for 20 minutes, and the chroma was 340 EBC.

[0050] c. The oats obtained in step b are dry ground to 100 mesh in a universal pulverizer. Weigh 30 kg of oat flour, slowly add it to the colloid mill for wet pulverization and defibrination.

[0051] d. Transfer the oat pulp obtained in step c to an enzymatic hydrolysis tank, set the volume to 75kg, add 50g of high-temperature-resistant α-amylase, heat up to 70°C, and maintain for 30min to gelatinize and liquefy the starch. Take a sample to measure the DE value of 25%.

[0052] e. Cool the enzymolysis tank to 55°C, add 0.8L 50g of al...

Embodiment 3

[0059] combine figure 1 Shown, the preparation method of charcoal burning oat milk, concrete steps are as follows:

[0060] a. Take about 40kg of oats (the oats imported from Australia imported from Ximai Oats Co., Ltd.) and wash them twice with 3 times the volume of water, and drain the water with a 40-mesh sieve.

[0061] b. The oats obtained in step a were baked in a drum drying oven at 180° C. for 30 minutes, and the chroma was 410 EBC.

[0062] c. The oats obtained in step b are dry ground to 100 mesh in a universal pulverizer. Weigh 30 kg of oat flour, slowly add it to the colloid mill for wet pulverization and defibrination.

[0063] d. Transfer the oat slurry obtained in step c to an enzymatic hydrolysis tank, set the volume to 75kg, add 40g of high-temperature-resistant α-amylase, heat up to 70°C, and maintain for 20min to gelatinize and liquefy the starch. Take a sample to measure the DE value of 24%.

[0064] e. The temperature of the enzymolysis tank was lowered t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com