MoS2/TiO2/Si pyramid array photoelectric catalyst and preparation method thereof

A pyramid and catalyst technology, applied in the field of nanomaterials, can solve the problems of unfavorable catalyst recycling, secondary pollution of water environment, complex and cumbersome treatment process, etc., and achieve the effect of promoting high-speed conduction, improving absorption efficiency, and reducing recombination probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

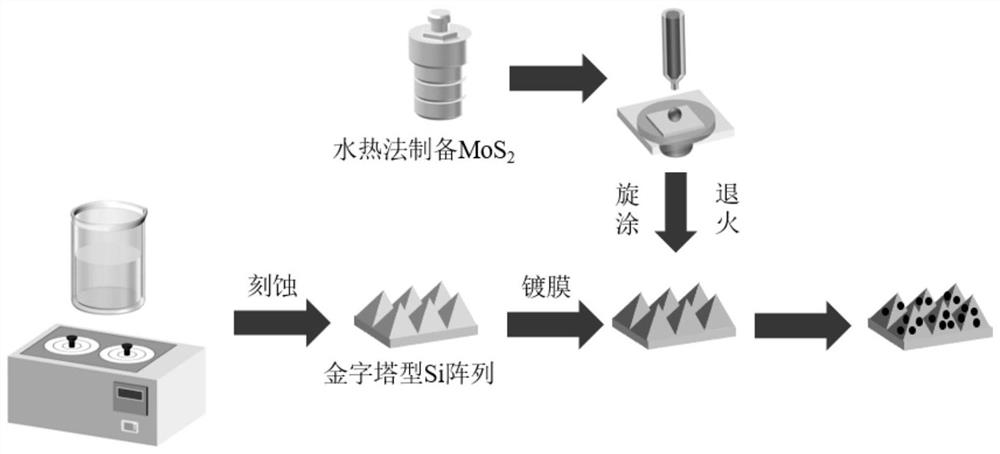

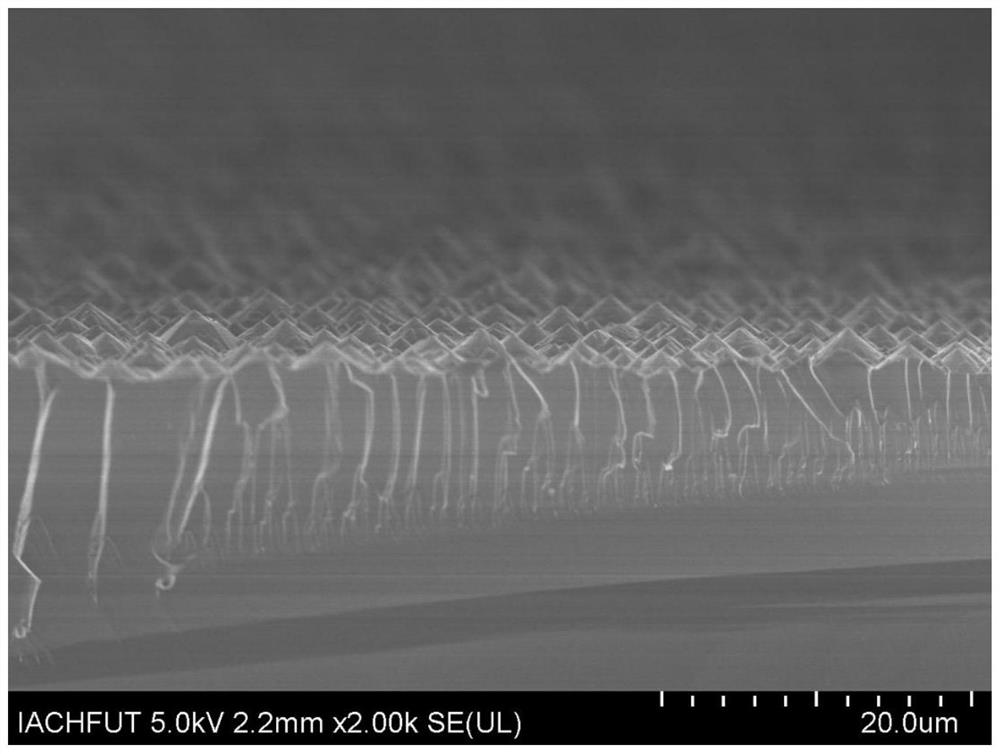

[0031] (1) Weigh 3g of KOH, 20mL of IPA (isopropanol) and 80mL of deionized water to prepare an alkaline etching solution. Immerse the pretreated silicon wafer in the etching solution, the etching temperature is 80°C, and the holding time is 2h, then rinse the surface of the etched silicon wafer with deionized water, and put it in a vacuum drying oven for drying treatment , to obtain a pyramidal silicon array for use;

[0032] (2) TiO 2 Put the ceramic target and pyramid-shaped silicon substrate into the magnetron sputtering equipment, adjust the sputtering power to 100W, the working pressure to 0.5Pa, and the sputtering time to 10min. After the sputtering is completed, the silicon wafer is ready for use;

[0033] (3) Add 0.4g of Na 2 MoO 4 2H 2 O, 0.38g of C 6 h 5 CH 2 SSCH 2 C 6 h 5 Mix well with 60mL of deionized water, then transfer to a 100mL autoclave for hydrothermal reaction, wherein the hydrothermal temperature is 220°C, and the hydrothermal time is 18h, to ...

Embodiment 2

[0039] (1) Weigh 3g of KOH, 20mL of IPA (isopropanol) and 80mL of deionized water to prepare an alkaline etching solution. Immerse the pretreated silicon wafer in the etching solution, the etching temperature is 80°C, and the holding time is 2h, then rinse the surface of the etched silicon wafer with deionized water, and put it in a vacuum drying oven for drying treatment , to obtain a pyramidal silicon array for use;

[0040] (2) Add 0.4g of Na 2 MoO 4 2H 2 O, 0.38g of C 6 h 5 CH 2 SSCH 2 C 6 h 5 Mix well with 60mL of deionized water, then transfer to a 100mL autoclave for hydrothermal reaction, wherein the hydrothermal temperature is 220°C, and the hydrothermal time is 18h, to obtain MoS 2 suspension;

[0041] (3) MoS 2 The suspension was washed and centrifuged three times with deionized water and absolute ethanol, and dried in a vacuum oven for 24 hours before use;

[0042] (4) Take 100mg MoS 2 Powder and pour into 10mL N-methylpyrrolidone organic solvent to co...

Embodiment 3

[0046] (1) Weigh 3g of KOH, 20mL of IPA (isopropanol) and 80mL of deionized water to prepare an alkaline etching solution. Immerse the pretreated silicon wafer in the etching solution, the etching temperature is 80°C, and the holding time is 2h, then rinse the surface of the etched silicon wafer with deionized water, and put it in a vacuum drying oven for drying treatment , to obtain a pyramidal silicon array for use;

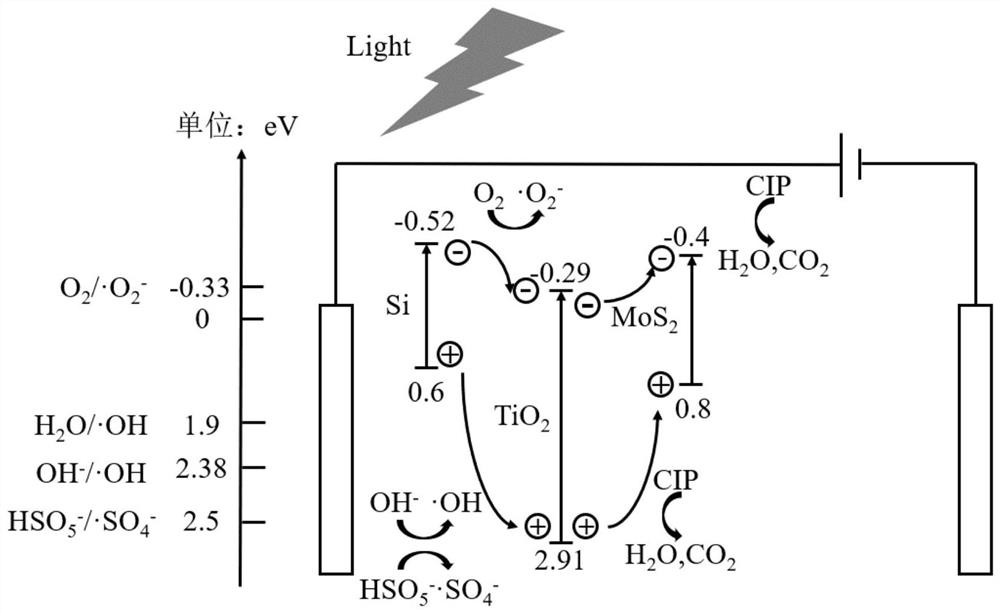

[0047] (2) Simulating sewage to investigate the performance of Si pyramid array photocatalysts

[0048] In the CHI660D electrochemical workstation, 100mL of ciprofloxacin with a concentration of 10mg / L was simulated as water source and 0.5MNa 2 SO 4 The electrolyte was added to a three-electrode electrolytic cell for photocatalytic experiments. Si pyramid array photocatalyst is used as the working electrode, Pt is used as the counter electrode, Ag / AgCl is used as the reference electrode, a xenon lamp light source with a power of 300W and a filter with a cut-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com