Preparation method and device of high-purity silicon tetrafluoride

A technology for preparing high-purity silicon tetrafluoride and equipment, applied in chemical instruments and methods, silicon halide compounds, halosilanes, etc., can solve problems such as high acidity, complex composition, and many impurities in silicon tetrafluoride, and achieve reduction Acidity, simple process, effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

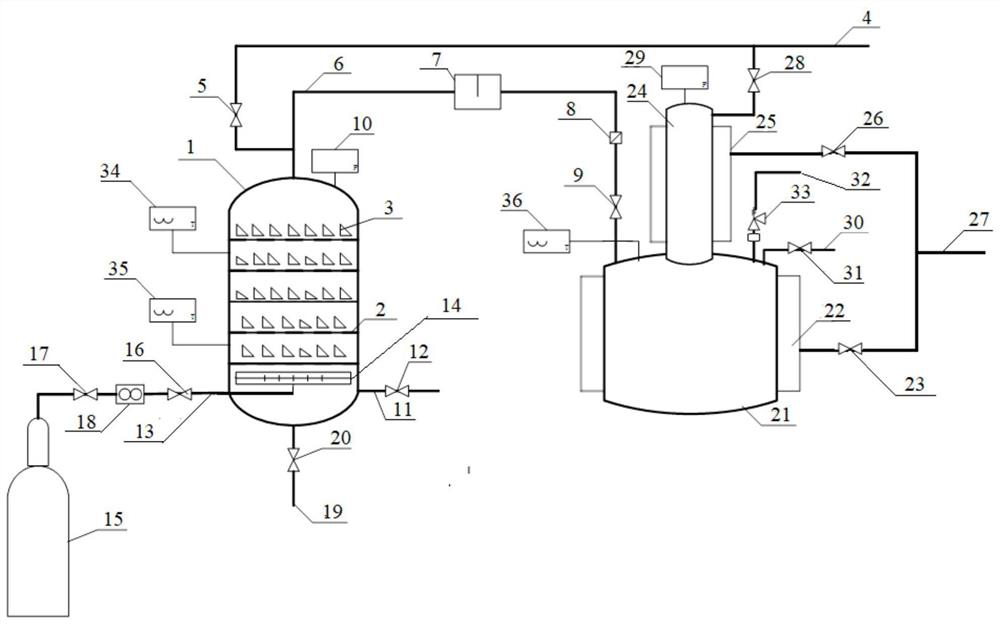

[0068] A kind of preparation method of high-purity silicon tetrafluoride, described method adopts such as figure 1 The preparation device of a kind of high-purity silicon tetrafluoride shown is carried out, and step is as follows:

[0069] ①Place the elemental silicon particles 3 with a particle size of 0.1mm in layers on the layered plate 2 in the reaction tower 1, raise the temperature to a displacement treatment temperature of 80°C, open the vacuum valve 5 of the reaction tower, and connect the reaction tower through the vacuum pipeline 4. 1. Vacuumize the interior to -0.095MPa, close the vacuum valve 5 of the reaction tower, open the replacement gas feed valve 12, feed helium gas with a purity of 99.999% through the replacement gas pipeline 11 until the inside of the reaction tower 1 is at normal pressure, and complete one pass Replacement treatment, repeat the replacement treatment 3 times, until the moisture content detected in the helium after the treatment is 0.4ppm, i...

Embodiment 2

[0079] A kind of preparation method of high-purity silicon tetrafluoride, described method adopts such as figure 1 The preparation device of a kind of high-purity silicon tetrafluoride shown is carried out, and step is as follows:

[0080] ① Place the elemental silicon particles 3 with a particle size of 3mm in layers on the layered plate 2 in the reaction tower 1, raise the temperature to a displacement treatment temperature of 150°C, open the vacuum valve 5 of the reaction tower, and pass the vacuum line 4 to the reaction tower 1. Vacuumize the interior to -0.095MPa, close the vacuum valve 5 of the reaction tower, open the replacement gas feed valve 12, and feed helium gas with a purity of 99.999% through the replacement gas pipeline 11 until the inside of the reaction tower 1 is at normal pressure, and complete one round of replacement treatment, repeat the replacement treatment 8 times, until the moisture content detected in the helium after the treatment is 0.3ppm, indica...

Embodiment 3

[0090] A kind of preparation method of high-purity silicon tetrafluoride, described method adopts such as figure 1 The preparation device of a kind of high-purity silicon tetrafluoride shown is carried out, and step is as follows:

[0091] ① Place the elemental silicon particles 3 with a particle size of 1.5mm in layers on the layered plate 2 in the reaction tower 1, raise the temperature to a displacement treatment temperature of 120°C, open the vacuum valve 5 of the reaction tower, and connect the reaction tower through the vacuum pipeline 4. Vacuumize the inside of 1 to -0.095MPa, close the vacuum valve 5 of the reaction tower, open the replacement gas feed valve 12, and feed helium with a purity of 99.999% through the replacement gas pipeline 11 until the inside of the reaction tower 1 is at normal pressure, and complete one pass Replacement treatment, repeat the replacement treatment 5 times, until the moisture content detected in the helium after the treatment is 0.4ppm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com