Anti-bleeding agent for concrete, preparation method of anti-bleeding agent, concrete admixture and concrete

A technology for concrete and water agent, applied in the fields of concrete, anti-bleeding agent for concrete and its preparation, and concrete admixture, can solve the problems of poor workability and loss of concrete fluidity over time, so as to reduce the overall cost and reduce the production cost. Water rate, the effect of reducing bleeding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

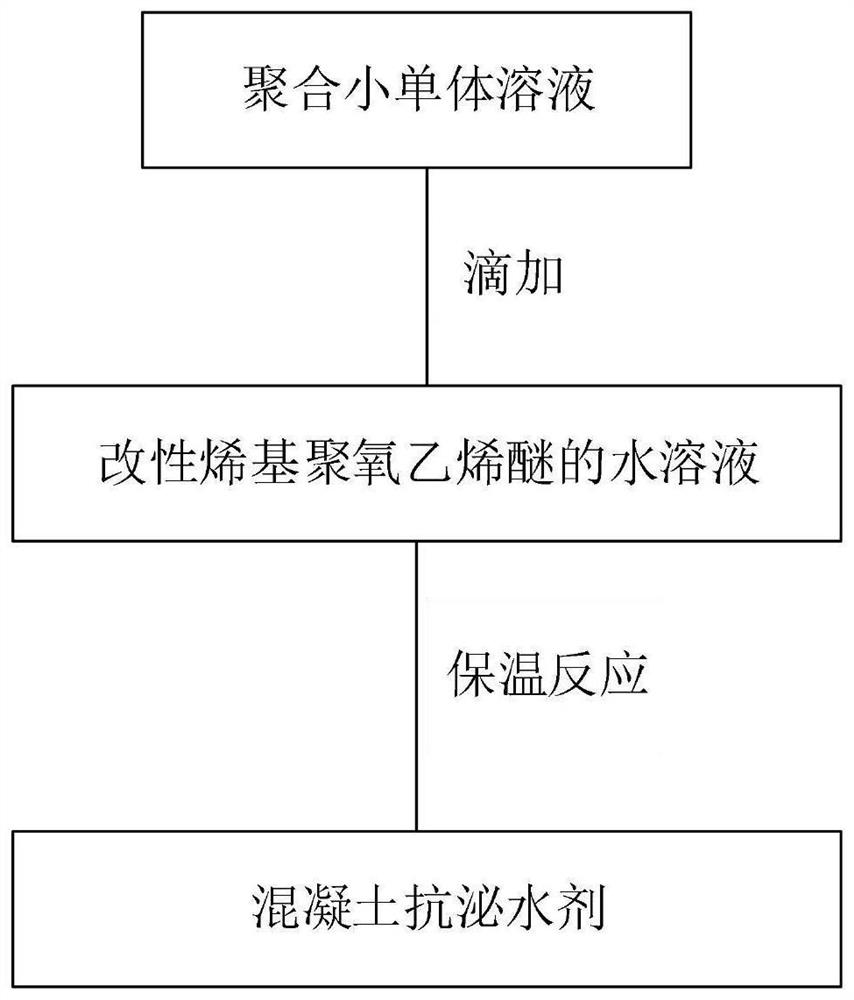

[0020] In order to solve the above technical problems, such as figure 1 As shown, the present invention provides a preparation method of an anti-bleeding agent for concrete, comprising: adding small polymerized monomers, reducing agents and chain transfer agents into a dripping tank to obtain a solution of small polymerized monomers; The modified alkenyl polyoxyethylene ether and the oxidizing agent are added to the reaction vessel to prepare the modified alkenyl polyoxyethylene ether solution; the polymerized small monomer solution is added dropwise to the modified alkenyl polyoxyethylene ether solution, and the insulation reaction is carried out Finally, the concrete anti-bleeding agent is prepared.

[0021] Specifically, the modified alkenyl polyoxyethylene ether, oxidizing agent and water are added into the reaction vessel in turn and fully stirred and dissolved to prepare an aqueous solution containing 30-60 wt% of the modified alkenyl polyoxyethylene ether; the polymeriz...

Embodiment 1

[0038] Add 1000 parts by mass of water, 1200 parts by mass of isopentenyl polyoxyethylene ether, 5 parts by mass of hydrogen peroxide, and 2 parts by mass of peracetic acid in the reaction kettle, and stir evenly; add 100 parts by mass of water, ascorbic acid 1 part by mass, 1 part by mass of ammonium bisulfite, 9 parts by mass of mercaptopropionic acid, 50 parts by mass of acrylic acid, and 200 parts by mass of hydroxypropyl acrylate, and stir evenly to obtain a dropwise solution. The reactor was controlled by a constant temperature water bath to maintain 35 degrees Celsius. At the same time, turn on the DC frequency conversion peristaltic pump under the dripping tank, control the pump speed so that the dripping liquid is added to the reactor at a uniform speed, and the addition is completed within 30 minutes. 70 parts by mass of 40% sodium hydroxide solution and 1032 parts by mass of water were added after the heat preservation reaction for 60 minutes. The anti-bleeding age...

Embodiment 2

[0041]Add 500 parts by mass of water, 500 parts by mass of methallyl polyoxyethylene ether, 1 part by mass of hydrogen peroxide, and 2 parts by mass of ammonium persulfate into the reactor, and stir evenly; add 100 parts by mass of water to the dropping tank successively, 0.2 parts by mass of sodium formaldehyde sulfoxylate, 0.8 parts by mass of sodium bisulfite, 3 parts by mass of thioglycolic acid, 90 parts by mass of acrylic acid, 50 parts by mass of maleic anhydride, 300 parts by mass of hydroxyethyl acrylate, stirred evenly and added dropwise liquid. The reactor was controlled by a constant temperature water bath to maintain 25 degrees Celsius. At the same time, turn on the DC frequency conversion peristaltic pump under the dripping tank, control the pump speed so that the dripping liquid is added to the reactor at a uniform speed, and the addition is completed within 60 minutes. After 45 minutes of heat preservation reaction, 227 parts by mass of 40% sodium hydroxide so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com