Polypyrrole/zirconium carbide/polyurethane composite fiber membrane as well as preparation method and application thereof

A composite fiber film and polyurethane technology, applied in fiber treatment, fiber type, spinning solution preparation, etc., can solve the problem of clothing losing air permeability and flexibility, and achieve the effect of unique and novel process and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

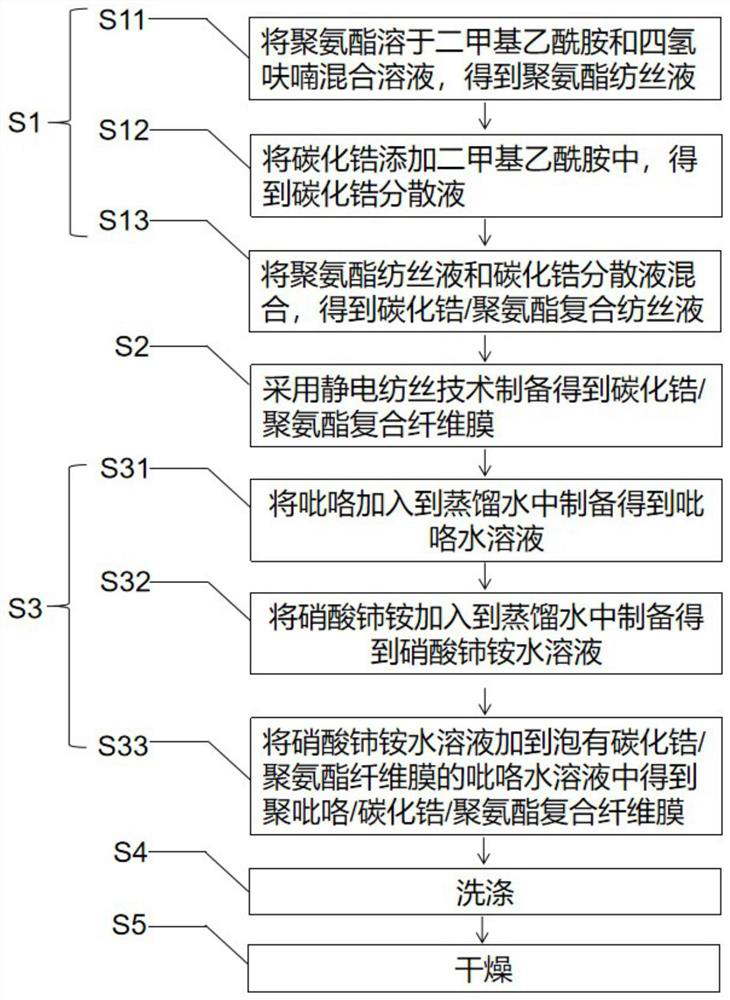

[0046] Such as figure 1 Shown, the preparation method of polypyrrole / zirconium carbide / polyurethane composite fiber film of the present invention comprises the steps:

[0047] (1) Add zirconium carbide and polyurethane to the mixed solution of dimethylacetamide and tetrahydrofuran to obtain zirconium carbide / polyurethane mixed spinning solution.

[0048] (1-1), dissolving polyurethane in dimethylacetamide and tetrahydrofuran mixed solution, stirring to obtain polyurethane spinning solution;

[0049] (1-2), then a certain amount of zirconium carbide is added in the dimethylacetamide solution to obtain a zirconium carbide dispersion;

[0050] (1-3). Finally, the polyurethane spinning solution is mixed with the zirconium carbide dispersion to obtain a zirconium carbide / polyurethane mixed spinning solution.

[0051](2) Prepare the zirconium carbide / polyurethane composite fiber membrane by using an electrospinning machine to prepare the zirconium carbide / polyurethane mixed spinni...

Embodiment

[0072] The preparation method of the polypyrrole / zirconium carbide / polyurethane composite fiber membrane of the present embodiment comprises the steps:

[0073] (1) Mix dimethylacetamide and tetrahydrofuran with a mass ratio of 1:1, add polyurethane and continuously stir for 8 hours at room temperature with a magnetic stirring device to obtain a polyurethane spinning solution with a solid content of 25%.

[0074] (2) Next, a certain amount of zirconium carbide was added into the dimethylacetamide solution, and then ultrasonically oscillated in a water bath at 35° C. for 30 minutes to obtain a zirconium carbide dispersion with a solid content of 25%.

[0075] (3) Finally, the polyurethane spinning solution and the zirconium carbide dispersion are mixed to obtain a zirconium carbide / polyurethane mixed spinning solution, wherein the zirconium carbide dispersion accounts for 4% of the mass sum of the zirconium carbide dispersion and the polyurethane spinning solution.

[0076] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com