A kind of preparation method of graphene antibacterial yarn

A technology of graphene and graphene solution, which is applied in the field of textile production, can solve the problems of non-permanent antibacterial, body damage, and easy elution of antibacterial substances, and achieve the effects of long-lasting antibacterial time, improvement of odor, and wide application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

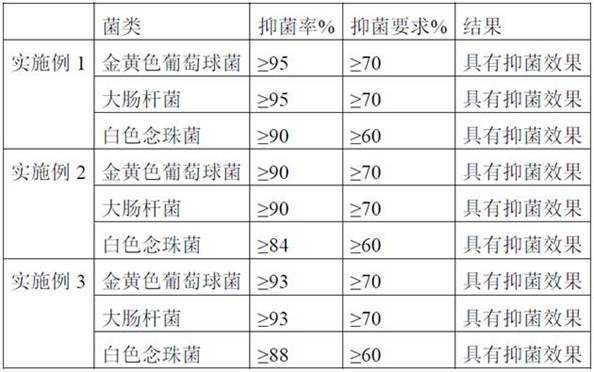

Embodiment 1

[0027] A preparation method of graphene antibacterial yarn, the preparation method is the following steps:

[0028] S.1 ultrasonically vibrate the 0.7mg / ml graphene oxide solution for 25min, pour it into the immersion tank, turn on the vibrator at the bottom of the immersion tank, the yarn immersion time is 1.0h, and the over-rolling rate is 60%. The yarn is pad-coated in the solution, and the yarn is in a semi-drying state after being dried in an oven channel at 50 °C for 1.0 h;

[0029] S.2 In 0.6mg / ml cinnamaldehyde solution, add photoinitiator, stir and mix well, the concentration of photoinitiator is 3.8ug / ml, soak the graphene yarn treated in S.1 in the mixture, heat Under the condition of 60°C and 73Hz frequency, after ultrasonic vibration for 10min, placed under 400uw / cm² intensity UV lamp for 25min, and finally the yarn was taken out for natural cooling and then passed through the oven channel to be dried and shaped, and the graphite can be obtained by winding. Antib...

Embodiment 2

[0031] A preparation method of graphene antibacterial yarn, the preparation method is the following steps:

[0032] S.1 ultrasonically vibrate the 0.2mg / ml graphene oxide solution for 20min, pour it into the immersion tank, turn on the vibrator at the bottom of the immersion tank, the yarn immersion time is 0.5h, and the over-rolling rate is 55%. The yarn is pad-coated in the solution, and the yarn is in a semi-dry state after being dried in an oven channel at 55°C for 0.5h;

[0033] S.2 In 0.3mg / ml cinnamaldehyde solution, add photoinitiator, stir and mix well, the concentration of photoinitiator is 3.0ug / ml, soak the graphene yarn treated in S.1 in the mixture, heat Under the condition of 55℃ and 60Hz frequency, after ultrasonic vibration for 15min, placed under the ultraviolet lamp of 380uw / cm² intensity for 30min. Finally, the yarn was taken out for natural cooling and then passed through the oven channel to be dried and shaped, and the graphite can be obtained by winding....

Embodiment 3

[0035] A preparation method of graphene antibacterial yarn, the preparation method is the following steps:

[0036] S.1 ultrasonically vibrate the 0.5mg / ml graphene oxide solution for 30min, pour it into the immersion tank, turn on the vibrator at the bottom of the immersion tank, the yarn immersion time is 0.8h, and the over-rolling ratio is 45%. The yarn is pad-coated in the solution, and the yarn is in a semi-dry state after being dried in an oven channel at 60°C for 0.7h;

[0037] S.2 In 0.45mg / ml cinnamaldehyde solution, add photoinitiator, stir and mix well, the concentration of photoinitiator is 2.5ug / ml, soak the graphene yarn treated in S.1 in the mixture, heat Under the condition of 70°C and 80Hz frequency, after ultrasonic vibration for 20min, placed under 420uw / cm² intensity UV lamp for 35min irradiation, finally the yarn was taken out for natural cooling, and then dried and shaped through the oven channel, and the graphite can be obtained by winding. Antibacteria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com