Method for constructing multi-field coupling artificial synapse through manganese oxide electromagnetic regulation and control

A manganese oxide, electromagnetic technology, applied in the manufacture/processing of electromagnetic devices, electrical components, material selection, etc., can solve the problems of limiting the plasticity of simulated synaptic functions, unfavorable continuous regulation of resistance, etc., to achieve the effect of expanding application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

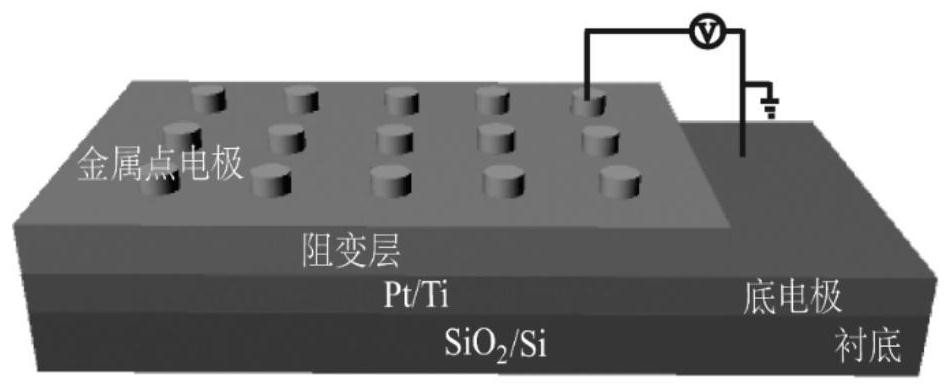

[0051] A component that mimics synapse function, its structure is metal / perovskite manganese oxide / (Pt / Ti) / (SiO 2 / Si), the preparation method comprises the following steps:

[0052] (1)CeO 2 Target preparation: weighing CeO 2 powder, and then tableted according to the desired target size; the flake CeO 2 Put it into a cleaned crucible and place it in a muffle furnace, and calcinate at 1200°C for 30h to obtain the desired CeO 2 Ceramic target.

[0053] (2)La 2 / 3 Ba 1 / 3 MnO 3 Target preparation:

[0054] Pretreatment: Weigh La 2 o 3 Powder, BaCO 3 powder, MnO 2 Powder, on La 2 o 3 The powder was pre-fired in a low-temperature furnace at 900°C for 8 hours to dry it.

[0055] Solid state sintering: according to stoichiometric ratio La 2 o 3 Powder, BaCO 3 powder, MnO 2 Put the powder in an agate mortar and grind it well to mix it evenly. Then put the evenly ground powder into a cleaned crucible and place it in a high temperature furnace for annealing. After th...

Embodiment 2

[0059] A component that simulates synapse function, its structure is LSMO / CeO 2 / (Pt / Ti) / (SiO 2 / Si), the preparation method comprises the following steps:

[0060] (1)CeO 2 Ceramic target preparation: weighing CeO 2 powder, and then tableted according to the desired target size; the flake CeO 2 Put it into a cleaned crucible and sinter in a muffle furnace; calcinate at 1200°C for 30h to obtain the required CeO 2 Ceramic target.

[0061] (2) La 0.7 Sr 0.3 MnO 3 Ceramic target preparation:

[0062] Pretreatment: Weigh La 2 o 3 powder, SrCO 3 powder, MnO 2 Powder, on La 2 o 3 The powder was pre-fired in a low-temperature furnace at 900°C for 8 hours for drying.

[0063] Solid phase sintering: After weighing the raw materials according to the required stoichiometric ratio, grind them thoroughly to make them evenly mixed. Then put the above powder into a cleaned crucible and place it in a muffle furnace for sintering. In order to obtain a high-density ceramic targ...

Embodiment 3

[0071] The difference between embodiment 3 and embodiment 1 is that the number of layers of components is different, CeO 2 Thin films and LBMO (La 2 / 3 Ba 1 / 3 MnO 3 ) film preparation is different, the rest of the process is exactly the same.

[0072] Deposited on (Pt / Ti) / (SiO2) by pulsed laser 2 / Si) substrates sequentially prepared large-area CeO 2 , LSMO film and metal electrode Au. A KrF laser with a wavelength of 248nm was used as a light source for deposition, the laser frequency for growing thin films was 3Hz, and the laser energy was 450mJ. During the growth process, O was introduced into the vacuum chamber 2 As the working gas, the prepared oxygen pressure is 35Pa. CeO 2 The deposition temperature of the LSMO and LSMO films is 650°C, the deposition time is 40 and 10 minutes, respectively, and then annealed in situ for 30 minutes. After the annealing is completed, a metal gold film is deposited on it, the deposition temperature is room temperature, and the dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com