Perovskite thin film based on PbCl2 buffer layer and preparation method and application thereof

A perovskite and buffer layer technology, applied in the field of solar cells, can solve problems such as poor photovoltaic performance of solar cells, and achieve the effects of accelerating commercial development, wide absorption spectrum, and improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

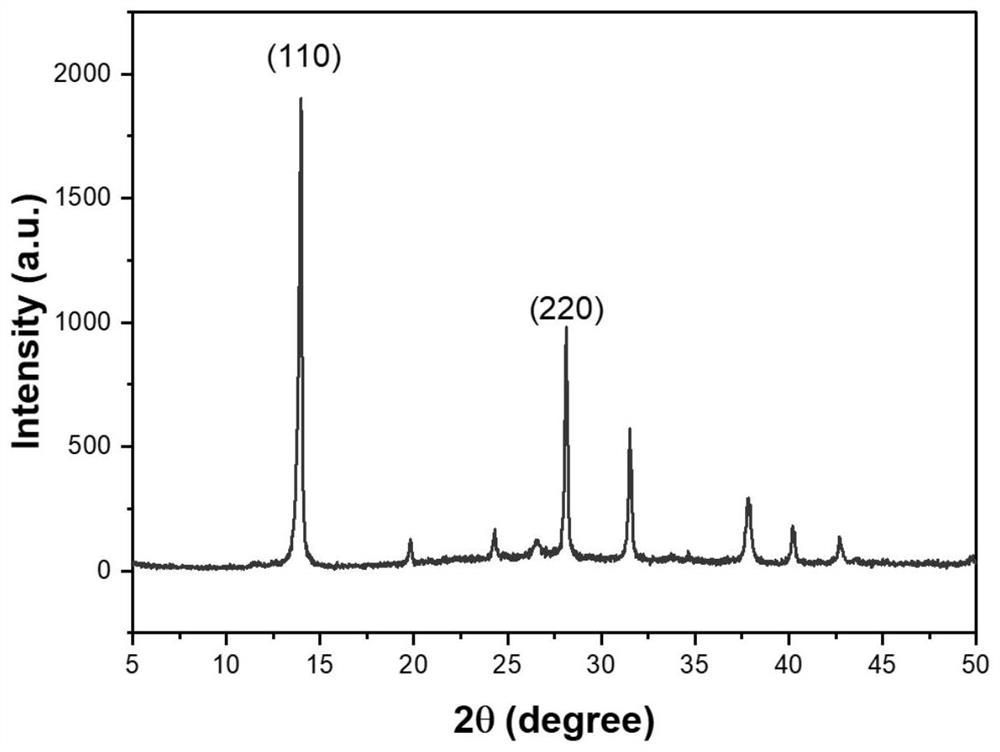

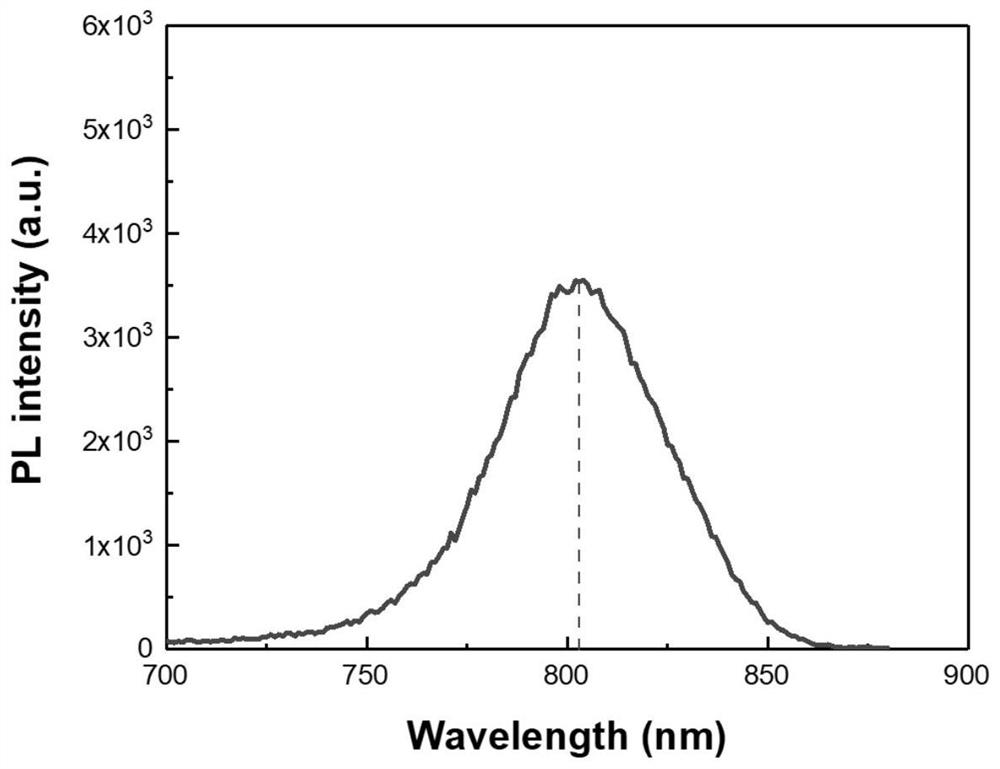

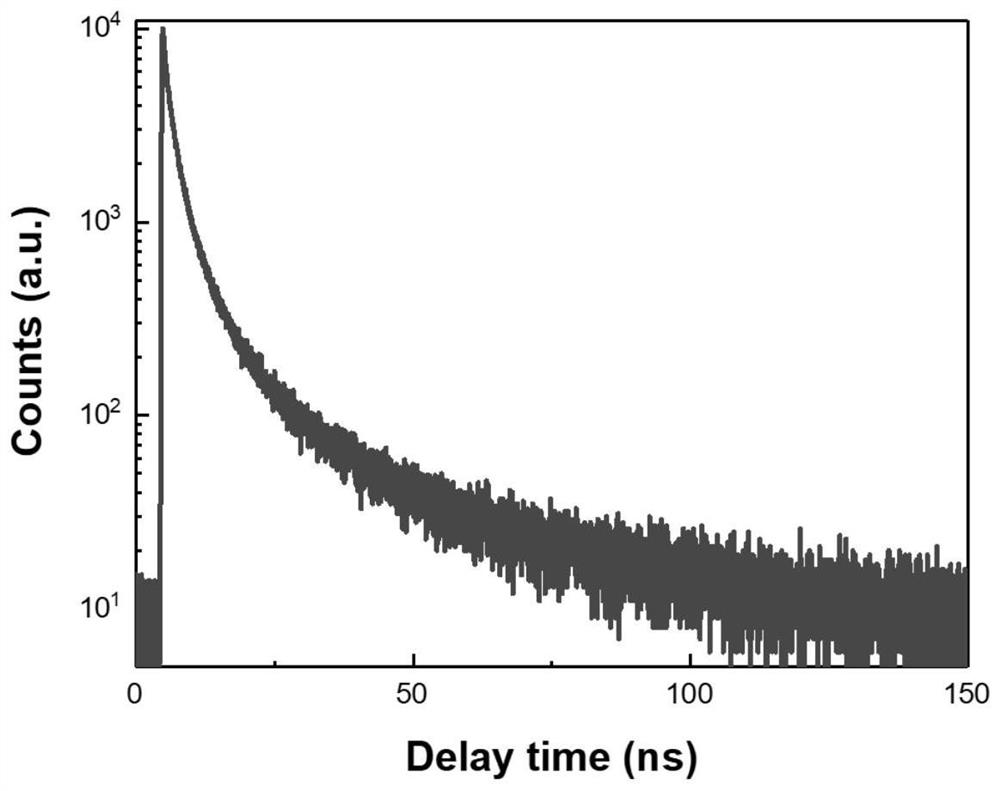

[0037] A PbCl-based 2 The preparation method of the perovskite thin film of interface buffer layer, comprises the following steps:

[0038] Step 1. Weigh PbCl 2 Powder, FAI and lead iodide are used as evaporation sources, respectively placed in the crucible, and then put into the evaporation furnace; and the cleaned substrate is placed on the sample rack in the vacuum chamber, the door is closed, the vacuum is drawn, and the vacuum degree reach 10 -4 At the Pa level, set the substrate temperature to 30°C, the substrate is an FTO substrate and has been deposited with C60 Electron transport layer;

[0039] Step 2. Adjust PbCl 2 The evaporation rate is Start to deposit PbCl after the rate stabilizes 2 Buffer layer, deposition thickness is 5nm, turn off the evaporation power, stop PbCl 2 Deposition, the substrate is kept rotating during the deposition process;

[0040] Step 3. Setting the substrate temperature to be 85°C, adjusting the evaporation molar ratio of FAI and le...

Embodiment 2

[0045] Figure 4 For the present invention based on PbCl 2 The device structure diagram of perovskite solar cells with interface buffer layer, from bottom to top are FTO substrate, C 60 Electron transport layer, PbCl 2 Interface buffer layer, FAPbI 3 Perovskite film, Spiro-OMeTAD hole transport layer and Au electrode layer. The preparation method of described perovskite solar cell comprises the following steps:

[0046] Step 1. Select FTO conductive glass as the substrate, use acetone, ethanol, and deionized water as solvents for ultrasonic treatment in turn, dry the ITO conductive glass after ultrasonic treatment with nitrogen, and then use oxygen plasma for 12 minutes, further Remove organic matter on the surface of the substrate, while enhancing the bonding force and adhesion on the surface of the substrate material;

[0047] Step 2. adopt evaporation method to prepare C on the FTO conductive glass substrate surface 60 Electron transport layer: place the FTO substrate...

Embodiment 3

[0054] According to the steps of Example 2, PbCl-based 2 Perovskite for interfacial buffer layer, only the PbCl in step 3 2 The deposition thickness is adjusted to 10nm and 20nm, and other steps remain unchanged.

[0055] The perovskite solar cells prepared in this example were analyzed for photovoltaic performance, and the results were as follows Image 6 shown, indicating that PbCl 2 Excessive thickness will adversely affect the photovoltaic performance of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com