Nano-selenium composite gel and preparation method thereof, and selenium supplement

A composite gel and nano-selenium technology, which is applied in the direction of anti-toxic agents, drug combinations, pharmaceutical formulations, etc., can solve the problems of low stability and biological activity of nano-selenium products, improve stability and anti-oxidation performance, and improve stability Sexuality, the effect of good market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention also proposes a preparation method of the above-mentioned nano-selenium composite gel, in one embodiment, the preparation method of the nano-selenium composite gel comprises the following steps:

[0053] Step S10, under stirring, sequentially add sodium hydroxide and sodium trimetaphosphate to the oxidized starch solution to obtain a solution A, and continue stirring until the solution A solidifies to obtain a starch gel.

[0054] The present invention does not limit the specific concentration and type of the oxidized starch solution, it can be a routinely used oxidized starch solution, in the present embodiment, the ratio of the quality of the oxidized starch in the oxidized starch solution to the volume of deionized water is (1-7) g: (50-200) mL, that is, 1 g: 50 mL, 3 g: 100 mL, 4 g: 100 mL, 5 g: 150 mL, 7 g: 100 mL, 7 g: 200 mL, etc. The oxidized starch may be corn oxidized starch, potato oxidized starch, etc. In one embodiment, corn oxidized s...

Embodiment 1

[0069] (1) Add 4 g of corn oxidized starch with a degree of oxidation of 30% into a beaker filled with 100 mL of deionized water, and stir to completely disperse the oxidized starch to obtain an oxidized starch solution; while stirring, add 0.8g of sodium hydroxide and 1.2g of sodium trimetaphosphate were used to obtain a solution A, and the stirring was continued until the solution A was solidified to obtain a starch gel, and then the starch microgel was refrigerated at 4°C for 12 hours for later use.

[0070] (2) The above-mentioned starch gel was passed through a 200-mesh sieve, washed with deionized water until neutral, redissolved in 100 mL of deionized water, and freeze-dried at -20°C for 12 hours to obtain starch microgel.

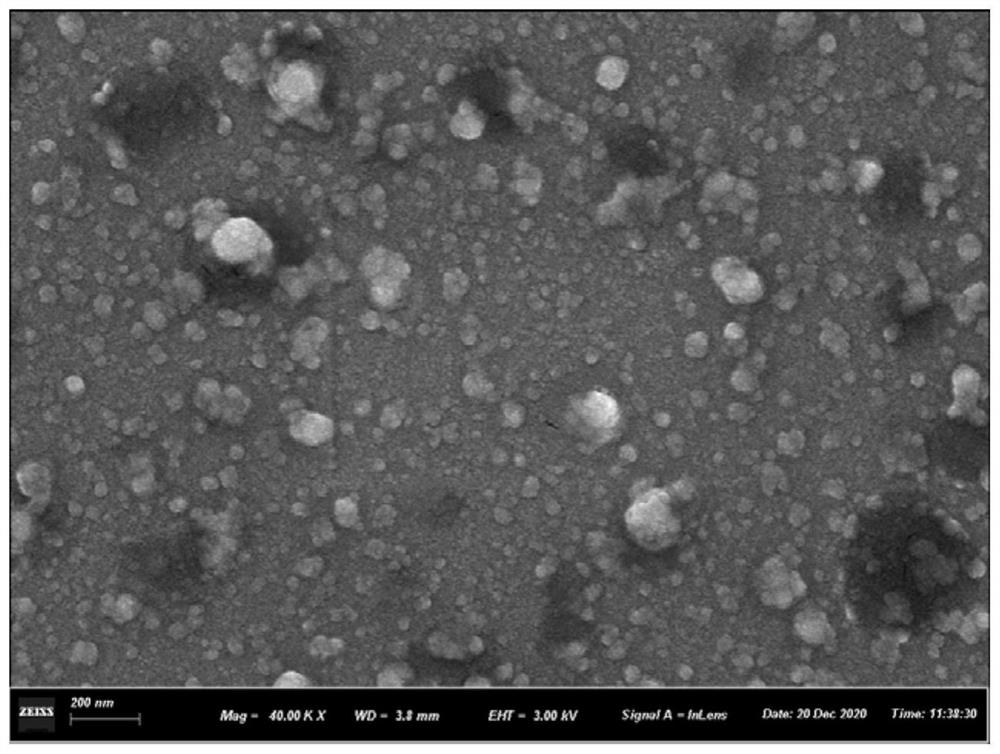

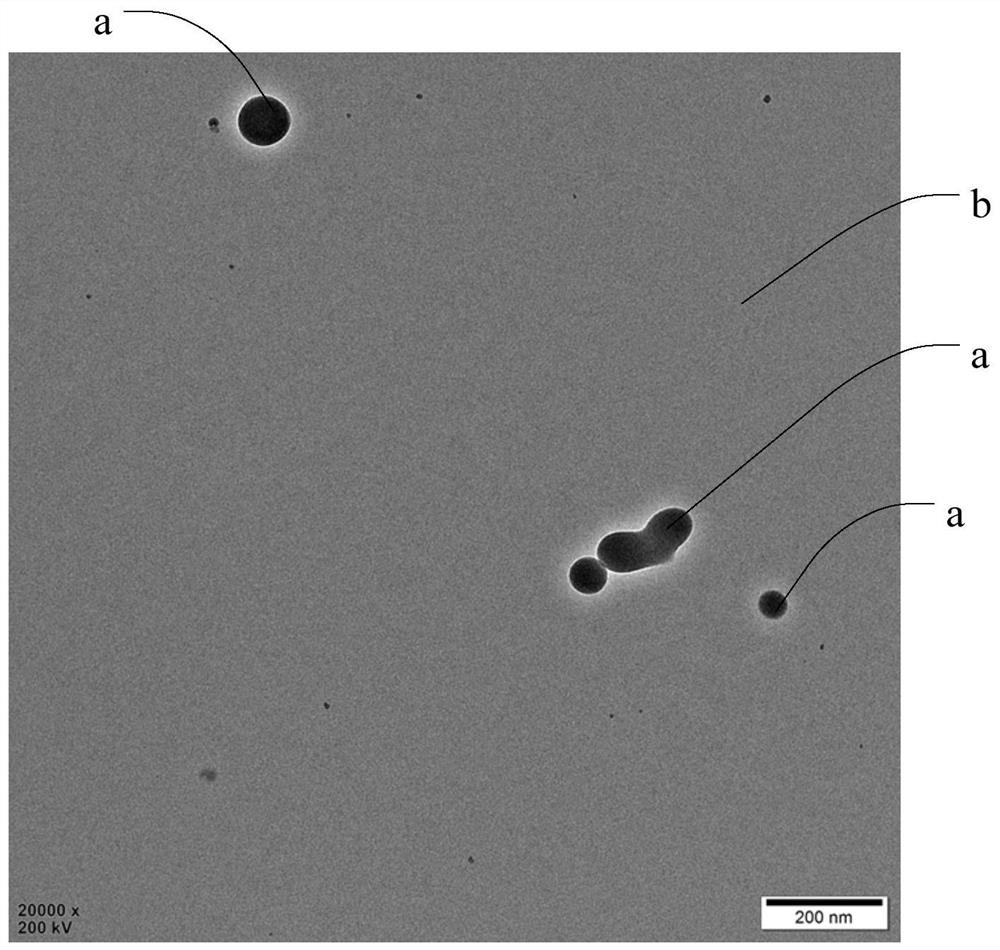

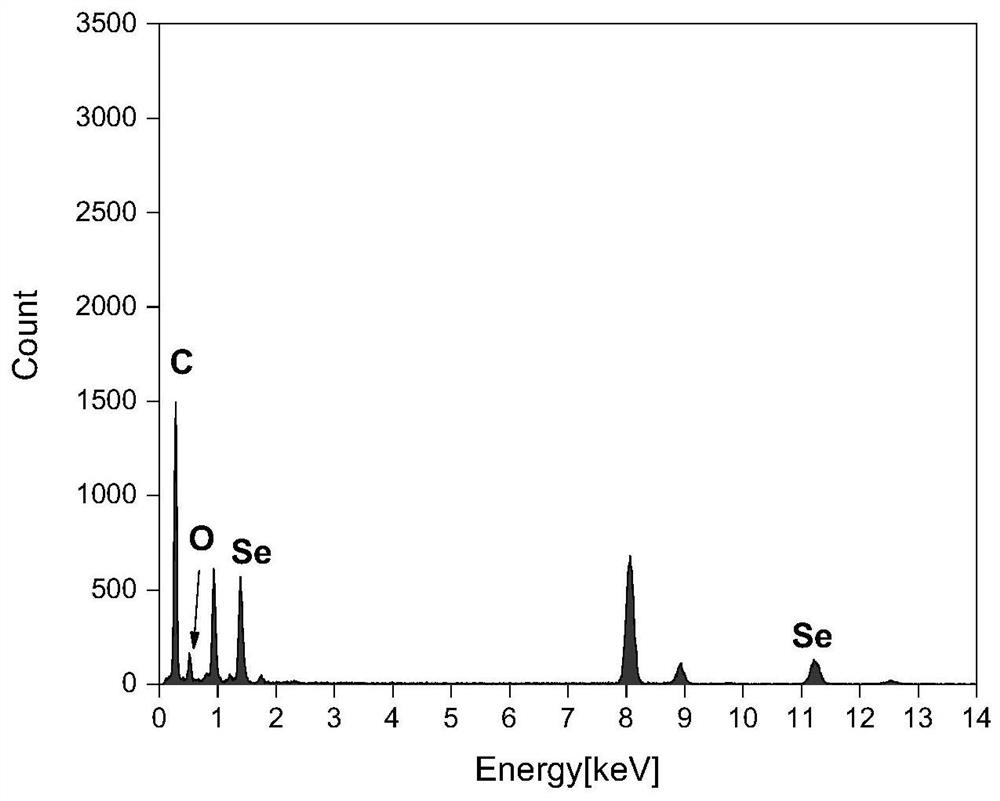

[0071] (3) 0.27 g of the above-mentioned starch microgel was dissolved in 300 mL of deionized water, and subjected to a high-pressure homogenization treatment at a pressure of 600 bar for 30 minutes to obtain a starch microgel solution.

[0072] (4)...

Embodiment 2

[0075] (1) Add 4 g of corn oxidized starch with a degree of oxidation of 30% into a beaker filled with 100 mL of deionized water, and stir to completely disperse the oxidized starch to obtain an oxidized starch solution; while stirring, add 0.8g of sodium hydroxide and 1.2g of sodium trimetaphosphate were used to obtain a solution A, and the stirring was continued until the solution A was solidified to obtain a starch gel, and then the starch microgel was refrigerated at 4°C for 12 hours for later use.

[0076] (2) The above-mentioned starch gel was passed through a 200-mesh sieve, washed with deionized water until neutral, redissolved in 100 mL of deionized water, and freeze-dried at -20°C for 12 hours to obtain starch microgel.

[0077] (3) 0.27 g of the above-mentioned starch microgel was dissolved in 300 mL of deionized water, and subjected to a high-pressure homogenization treatment at a pressure of 600 bar for 30 minutes to obtain a starch microgel solution.

[0078] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com