Preparation method of rapidly-thinned single-element tellurene two-dimensional material

A two-dimensional material and single-element technology, applied in the direction of element selenium/tellurium, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as few and unfavorable applications, and achieve strong controllability, simple process, and adaptability The effect of large-scale promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

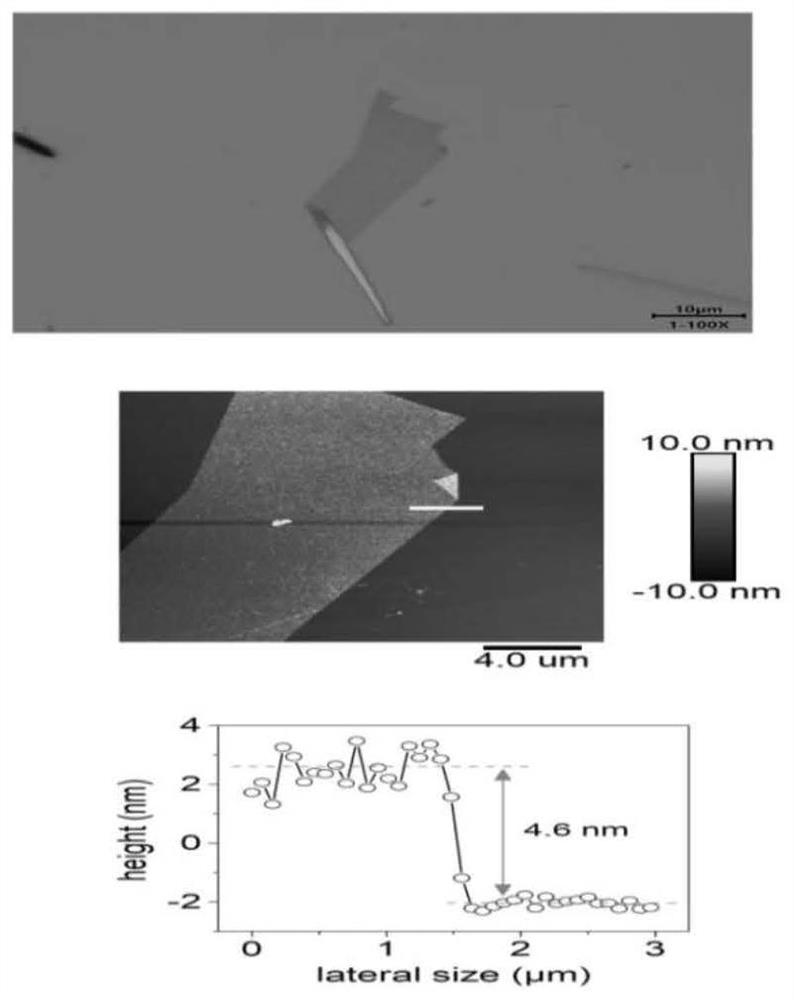

Embodiment 1

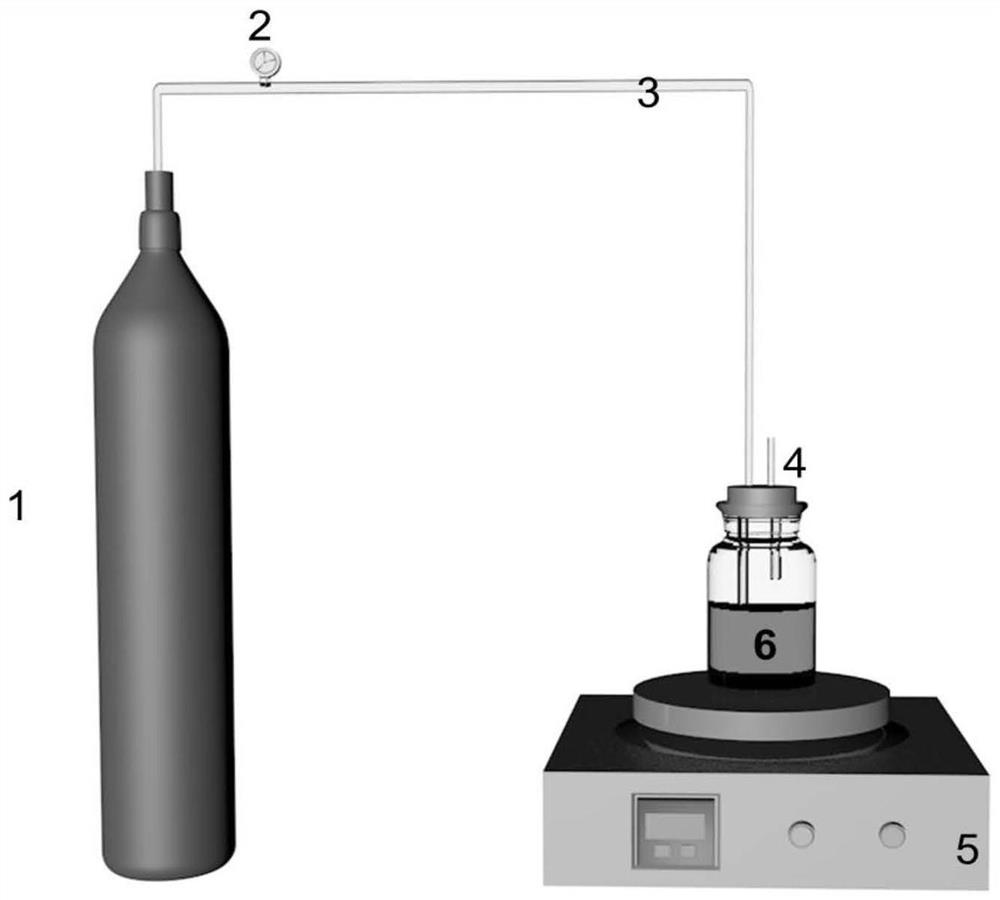

[0030] A preparation method for rapidly thinning a single-element tellurene two-dimensional material, specifically comprising the following steps:

[0031] (1) Preparation of single-element tellurene material precipitates by hydrothermal method: a) Weigh 1 g of polyvinylpyrrolidone and dissolve it in deionized water, and stir until the above aqueous solution is clear; b) Weigh 0.05 g of sodium tellurite and add it to the In the clarified aqueous solution described in step a), stir for 10 minutes, then add 1ml of ammonia water and 1ml of hydrazine hydrate in sequence, and continue stirring for 5 minutes to obtain a mixed solution; c) pour the mixed solution described in step b) into a hydrothermal reaction kettle , and then place the hydrothermal reaction kettle in an oven at 180° C. to grow for 6 hours; d) take out the reacted solution in the hydrothermal reaction kettle in step c), and wash it by centrifugation until the upper solution reaches a clear state, that is, Single-e...

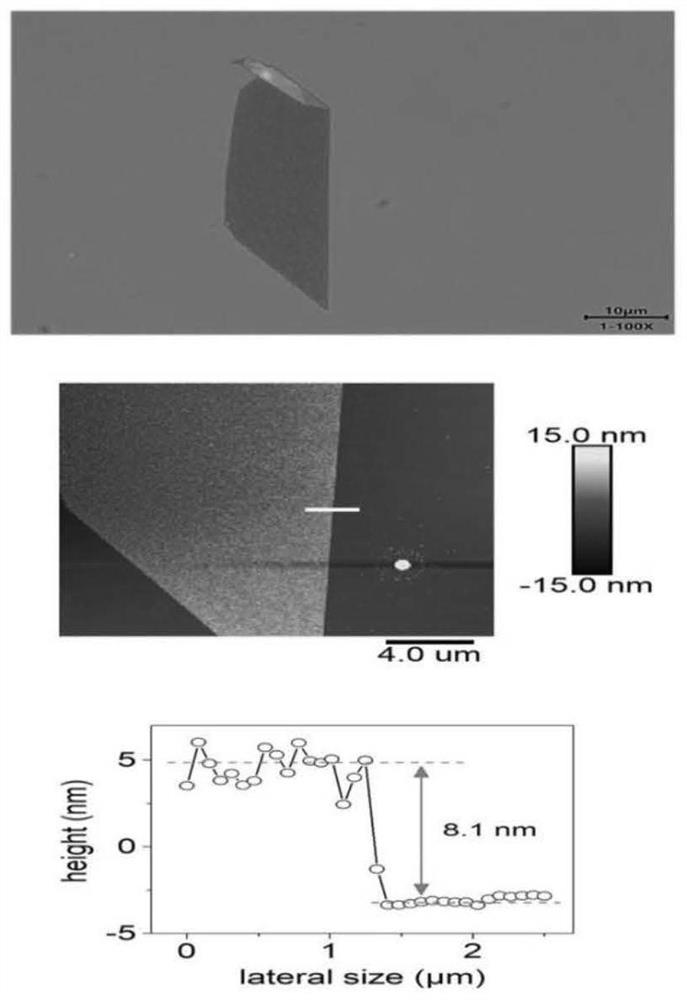

Embodiment 2

[0036] A preparation method for rapidly thinning a single-element tellurene two-dimensional material, specifically comprising the following steps:

[0037](1) Preparation of single-element tellurene material precipitate by hydrothermal method: a) Weigh 1.5g of octadecylamine and dissolve it in deionized water, and stir until the above aqueous solution is in a clear state; b) Weigh out 0.03g of tellurous acid Add sodium into the clear aqueous solution described in step a), stir for 20 minutes, then add 1.5ml of ammonia water and 1.5ml of hydrazine hydrate to it in turn, and continue stirring for 5 minutes to obtain a mixed solution; c) pour the mixed solution described in step b) into a hydrothermal reaction kettle, and then place the hydrothermal reaction kettle in an oven at 150° C. to grow for 4 hours; d) take out the reacted solution in the hydrothermal reaction kettle in step c), and wash it by centrifugation until the solution becomes clear state, that is, the single-elem...

Embodiment 3

[0042] A preparation method for rapidly thinning a single-element tellurene two-dimensional material, specifically comprising the following steps:

[0043] (1) Preparation of single-element tellurene material precipitate by hydrothermal method: a) Weigh 2 g of sodium lauryl sulfate and dissolve it in deionized water, and stir until the above aqueous solution is in a clear state; b) Weigh out 0.07 g of tellurous acid Add sodium into the clear aqueous solution described in step a), stir for 30 minutes, then add 2ml of ammonia water and 2ml of hydrazine hydrate to it in turn, and continue stirring for 5 minutes to obtain a mixed solution; c) pour the mixed solution described in step b) into water heat the reaction kettle, and then place the hydrothermal reaction kettle in an oven at 160° C. to grow for 7 hours; d) take out the reacted solution in the hydrothermal reaction kettle in step c), and centrifugally wash until the solution reaches a clear state, The single-element tellur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com