Flaky tin disulfide and preparation method and application thereof

A tin disulfide, flake technology, applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., can solve the problems of cycle stability and poor rate performance, and achieve improved electrochemical performance, good application value, and grain size big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

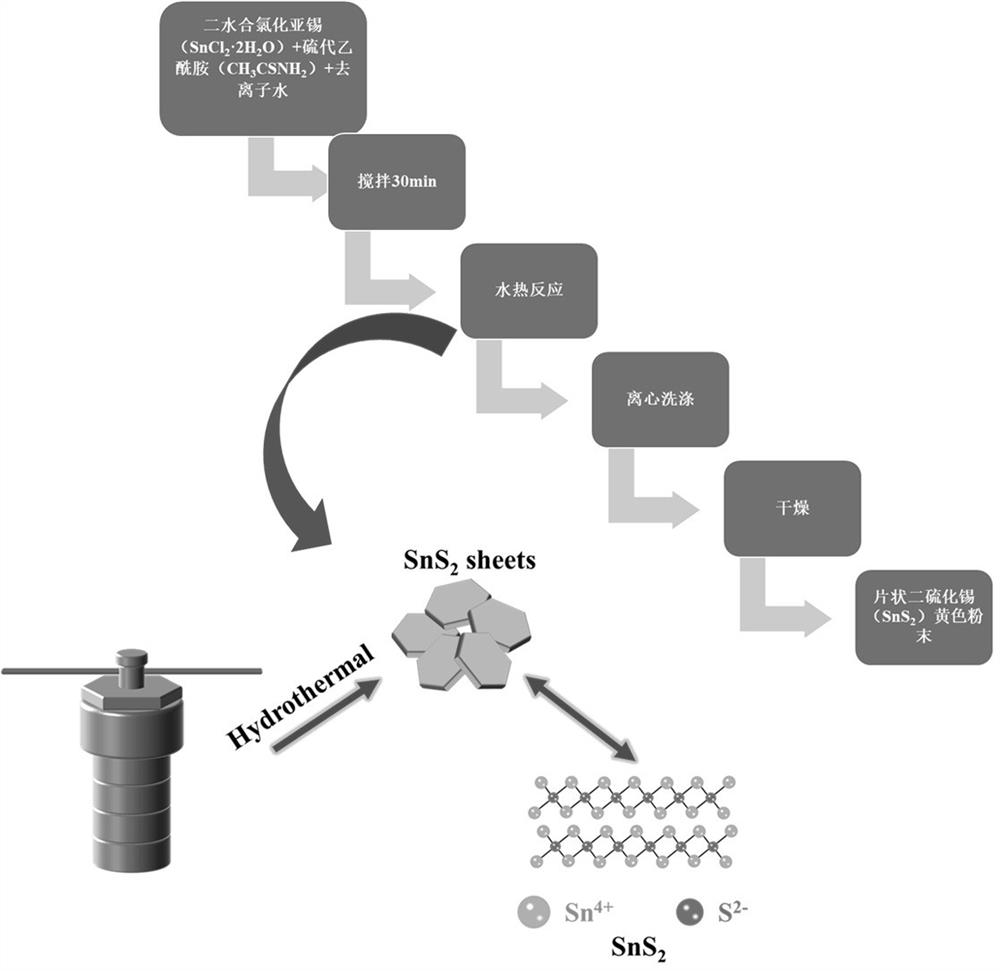

[0026] 1. Preparation of flaky tin disulfide.

[0027] like figure 1 As shown, the preparation process includes the following steps:

[0028] (1) Weigh 0.3949g of stannous chloride dihydrate (SnCl 2 ·2H 2 O) and 1.9722 g of thioacetamide (CH 3 CSNH 2 ) in a clean beaker, then add 35 ml of deionized water, and stir for about 30 minutes to mix thoroughly to obtain a mixed solution.

[0029] (2) Add an appropriate amount of ammonia water to the mixture to adjust the pH of the mixture to 8~9.

[0030] (3) Transfer the mixed solution after adjusting the pH value to an autoclave with a volume of 50ml, seal it and place it in an oven at 120°C for about 6 hours, until the reaction ends, and then take it out after the autoclave is cooled to room temperature. The reacted product is obtained.

[0031] (4) The product is centrifuged and washed three times with absolute ethanol, and the product is centrifuged and washed three times with deionized water to obtain the washed product, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com