Low-temperature sintered aluminum nitride ceramic material, aluminum nitride tape casting slurry and application

A low-temperature sintering technology for aluminum nitride ceramics, applied in the field of ceramic materials, can solve the problems of high sintering temperature of aluminum nitride ceramics, achieve good thermal conductivity, improve dispersion, reduce pores and glass phase effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0061] A low-temperature sintered aluminum nitride ceramic material prepared through the following steps:

[0062] Take 8 kg of micron-sized aluminum nitride ceramic powder with a median particle size D50 in the range of 2.2 μm and 2 kg of nano-sized aluminum nitride ceramic powder with a median particle size D50 in the range of 0.03 μm, and mix them to obtain aluminum nitride ceramic powder; Weigh 0.4kg of AlF at the same time 3 and 0.45kg of CaF 2 , to prepare a low-temperature sintered aluminum nitride ceramic material.

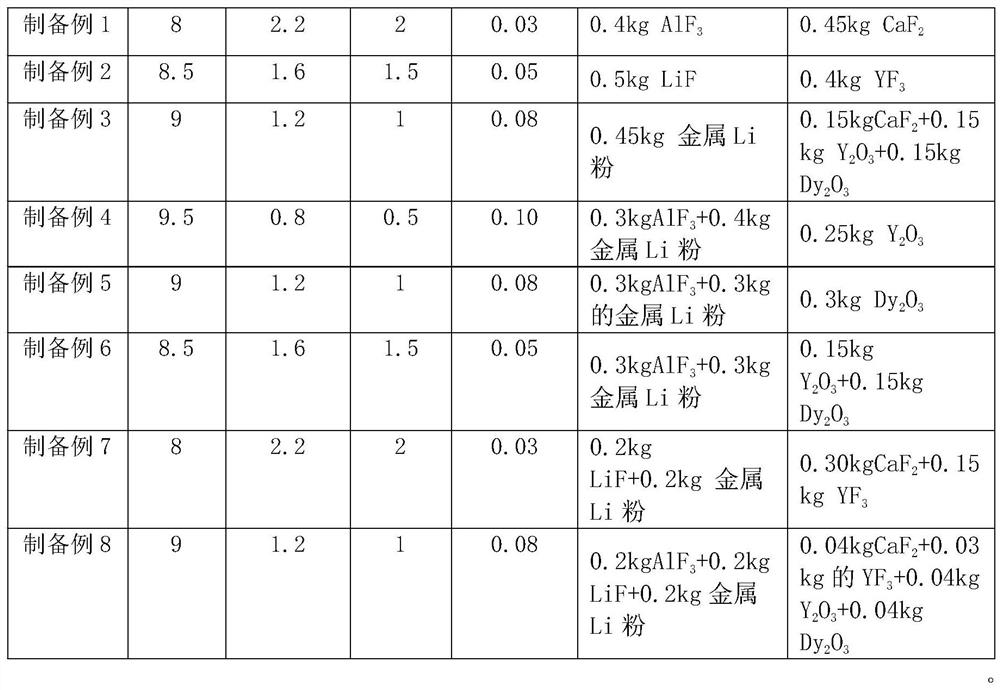

preparation example 2-8 and comparative preparation example 1

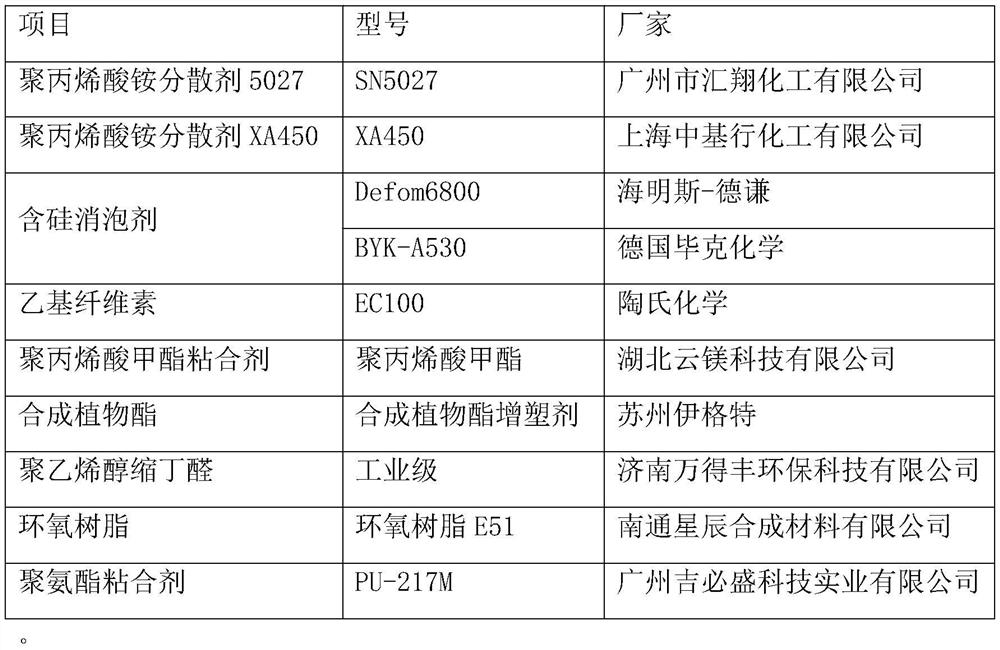

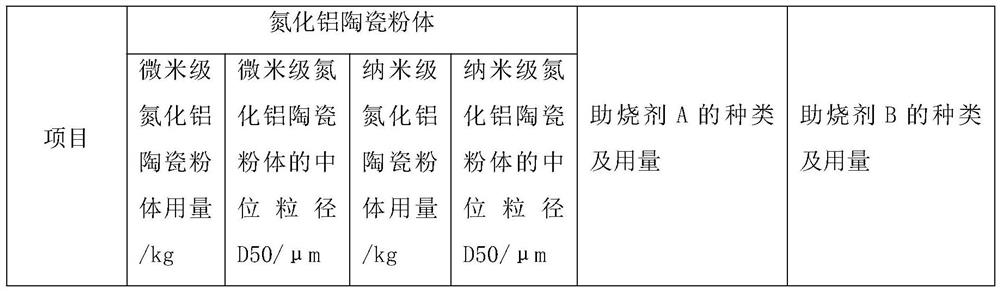

[0064] The difference between Preparation Examples 2-8 and Comparative Preparation Example 1 and the above Preparation Example 1 lies in the difference in the type and amount of materials, see Table 2 below for details;

[0065] Table 2 preparation examples 1-8 and comparative preparation example 1 material type, material consumption

[0066]

[0067]

Embodiment 1

[0070] A kind of aluminum nitride tape casting slurry is prepared through the following steps:

[0071] will diameter Zirconium balls, 1.1kg of absolute ethanol, 3.4kg of n-propyl acetate, 0.12kg of ammonium polyacrylate dispersant 5027 and 0.12kg of BYK-A530 defoamer were added to the barrel of the grinding equipment. 40%, stir until ammonium polyacrylate dispersant 5027 and BYK-A530 defoamer dissolve, then add 0.4kg of AlF 3 and 0.45kg of CaF 2 , ball milled to AlF at a speed of 1300rpm 3 and CaF 2 The median particle size D50 range of 0.3-0.5 μm, then add 10kg of the aluminum nitride ceramic powder of Preparation Example 1, continue ball milling at a speed of 1300rpm, and ball mill to the median particle size of the aluminum nitride ceramic powder After the D50 range is 0.8-1.2μm, stop the ball milling, add 0.75kg polyvinyl butyral and 0.75kg synthetic vegetable ester, stir evenly, ball mill for 40min at the speed of 1300rpm, discharge the material, and make it after v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com