Tundish cover castable and method for preparing tundish cover by using same

A castable and cladding technology, which is applied in the field of refractory materials, can solve the problems of burnout of the cladding metal structure frame, large consumption of spare parts, and little effect, and achieves optimized heat transfer characteristics, low thermal expansion coefficient, and improved microscopic effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

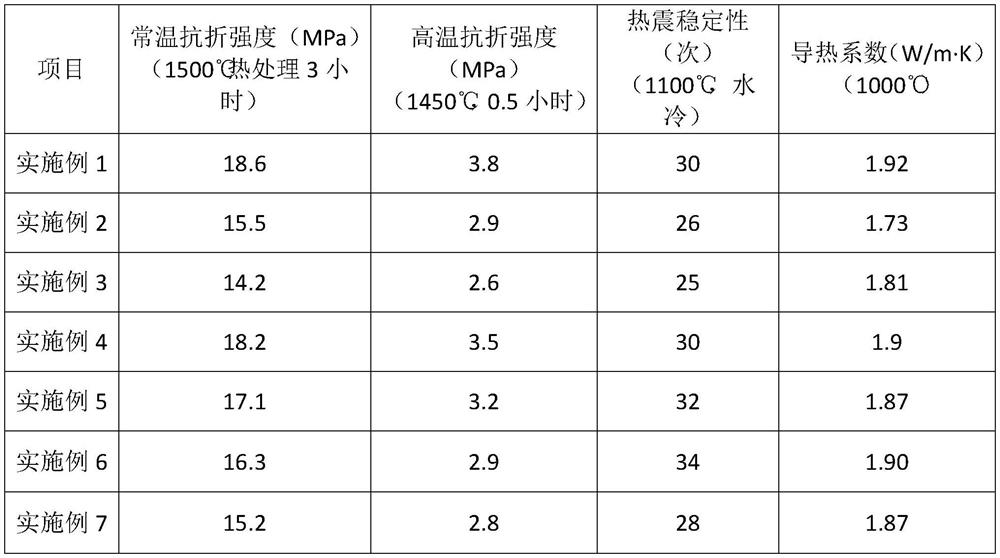

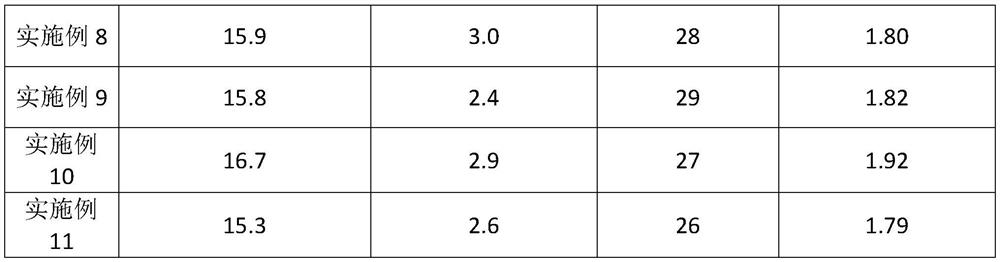

Examples

Embodiment 1

[0020] Mix 32wt% of glass powder, 20wt% of silicon carbide powder, 35wt% of silicon carbide particles, 5wt% of silicon micropowder, 4wt% of glucose, and 4wt% of water. Heat treatment at ℃ for 3 hours, cool to room temperature with the furnace, crush and sieve to obtain prefabricated powder with a particle size of less than 0.088mm and prefabricated granules with a particle size of 0.088-2mm.

[0021] With 55wt% alumina particles, 18wt% alumina fine powder, 2wt% silica powder, 3wt% prefabricated powder, 6wt% prefabricated particles, 4.75wt% alumina micropowder, 0.1wt% metal aluminum powder , 4wt% aluminate cement, 2wt% stainless steel fiber, 0.1wt% sodium tripolyphosphate, 0.05wt% propylene glycol alginate, add 5wt% water and stir evenly, put it in the mold for vibration molding, and then After standing still at room temperature for 24 hours and then heat-treating at 110° C. for 24 hours, the tundish cover is obtained.

Embodiment 2

[0023] Mix 35wt% of glass powder, 18wt% of silicon carbide powder, 34wt% of silicon carbide particles, 4wt% of silicon micropowder, 5wt% of glucose, and 4wt% of water. Heat treatment at -°C for 3 hours, cool down to room temperature with the furnace, crush and sieve to obtain prefabricated powder with a particle size of less than 0.088mm and prefabricated granules with a particle size of 0.088-2mm.

[0024] With 55wt% alumina particles, 18wt% alumina fine powder, 2wt% silica powder, 3wt% prefabricated powder, 6wt% prefabricated particles, 4.73wt% alumina micropowder, 0.1wt% metal aluminum powder , 4wt% aluminate cement, 2wt% stainless steel fiber, 0.1wt% sodium tripolyphosphate, 0.07wt% propylene glycol alginate, and 5wt% water were stirred evenly, then placed in a mold for vibration molding, and then successively After standing still at room temperature for 24 hours and heat-treating at 110° C. for 24 hours, the tundish cover is obtained.

Embodiment 3

[0026] Mix 40wt% of glass powder, 20wt% of silicon carbide powder, 29wt% of silicon carbide particles, 2wt% of silicon micropowder, 5wt% of glucose, and 4wt% of water. Heat treatment at ℃ for 3 hours, cool to room temperature with the furnace, crush and sieve to obtain prefabricated powder with a particle size of less than 0.088mm and prefabricated granules with a particle size of 0.088-2mm.

[0027] With 55wt% alumina particles, 18wt% alumina fine powder, 2wt% silica powder, 3wt% prefabricated powder, 6wt% prefabricated particles, 4.75wt% alumina micropowder, 0.1wt% metal aluminum powder , 4wt% aluminate cement, 2wt% stainless steel fiber, 0.1wt% sodium tripolyphosphate, 0.05wt% propylene glycol alginate, and 5wt% water were stirred evenly, then placed in a mold for vibration molding, and then successively After standing still at room temperature for 24 hours and heat-treating at 110° C. for 24 hours, the tundish cover is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com