Viscosity-reducing water reducing agent and preparation method and application thereof

A water reducing agent and viscosity reducing technology, applied in the field of viscosity reducing water reducing agent and its preparation, can solve the problems of prolonging construction progress, increasing cost, increasing construction, etc., and achieve the effect of slow flow rate, reduced viscosity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

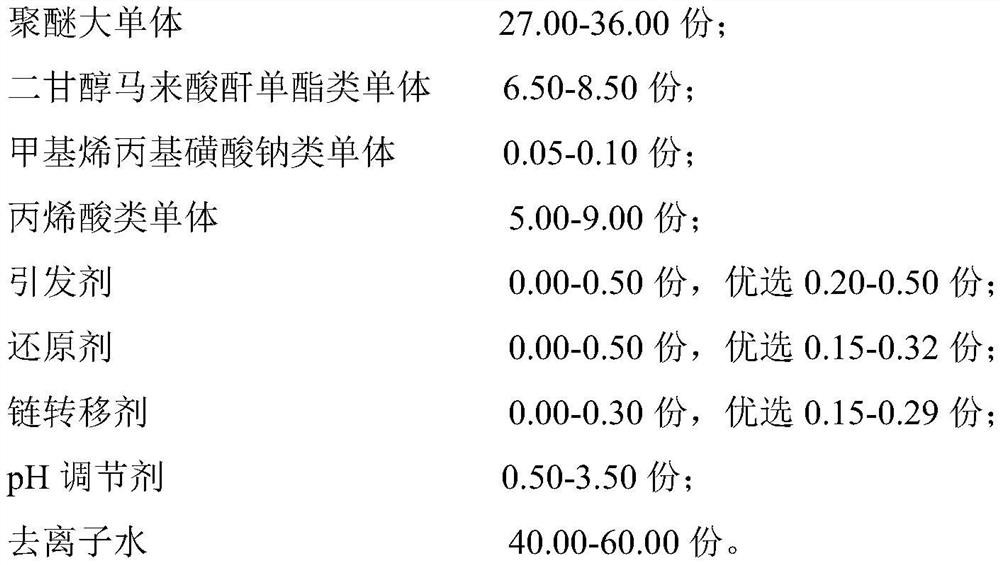

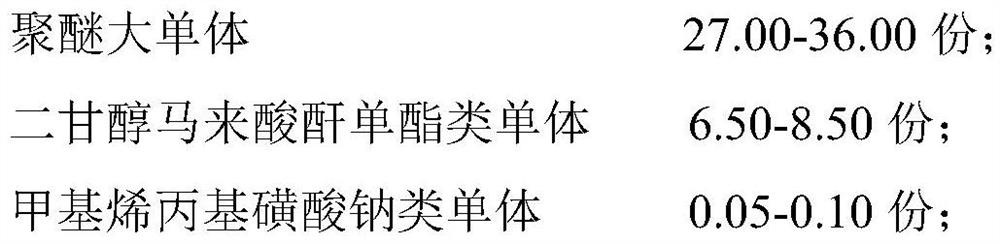

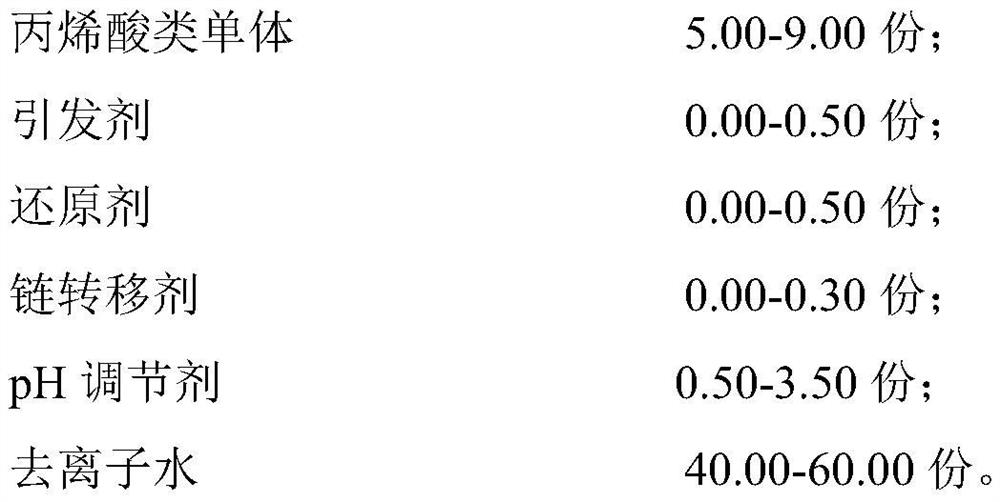

Method used

Image

Examples

Embodiment 1

[0044] Example 1 The main components of synthesizing a novel viscosity-reducing and water-reducing agent are: in parts by weight, 36.69 parts of polyether macromonomer, 3.82 parts of diethylene glycol maleic anhydride monoester monomer, methallyl sulfonic acid 0.092 parts of sodium monomer, 8.45 parts of acrylic monomer, 0.44 parts of initiator, 0.257 parts of reducing agent, 0.257 parts of chain transfer agent, 3.25 parts of pH adjusting solution and 46.75 parts of deionized water.

[0045] Embodiment 1 Synthesizing the preparation method of novel viscosity-reducing and water-reducing agent

[0046] (1) Put 36.69 parts of isopentenol polyoxyethylene ether (TPEG-1250), 0.092 parts of sodium methallyl sulfonate, 26.75 parts of deionized water and 0.44 parts of hydrogen peroxide in reaction flask A, and heat Dissolve at 30°C-40°C and mix uniformly to obtain Polymer I.

[0047] (2) Under normal temperature conditions, 0.257 parts of ascorbic acid (VC), 0.257 parts of β-mercaptop...

Embodiment 2

[0051] Example 2 The main components of synthesizing a novel viscosity-reducing and water-reducing agent are: by weight, 34.08 parts of polyether macromonomer, 7.09 parts of diethylene glycol maleic anhydride monoester monomer, methallyl sulfonic acid 0.085 parts of sodium monomer, 7.85 parts of acrylic monomer, 0.41 parts of initiator, 0.24 parts of reducing agent, 0.24 parts of chain transfer agent, 3.25 parts of pH adjusting solution and 46.75 parts of deionized water.

[0052] Embodiment 2 The preparation method of synthesizing novel viscosity-reducing water-reducing agent

[0053] (1) Put 34.08 parts of isopentenol polyoxyethylene ether (TPEG-1250), 0.085 parts of sodium methallyl sulfonate, 26.75 parts of deionized water and 0.41 parts of hydrogen peroxide in reaction flask A, and heat Dissolve at 30°C-40°C and mix uniformly to obtain Polymer I.

[0054] (2) Under normal temperature conditions, 0.24 parts of ascorbic acid (VC), 0.24 parts of β-mercaptopropionic acid and...

Embodiment 3

[0058] Example 3 The main components of synthesizing a novel viscosity-reducing and water-reducing agent are: in parts by weight, 31.83 parts of polyether macromonomer, 9.93 parts of diethylene glycol maleic anhydride monoester monomer, methallyl sulfonic acid 0.08 parts of sodium monomer, 7.33 parts of acrylic monomer, 0.38 parts of initiator, 0.22 parts of reducing agent, 0.22 parts of chain transfer agent, 3.25 parts of pH adjusting solution and 46.75 parts of deionized water.

[0059] Embodiment 3 Synthesizing the preparation method of novel viscosity-reducing and water-reducing agent

[0060] (1) Put 31.83 parts of isopentenol polyoxyethylene ether (TPEG-1250), 0.08 parts of sodium methallyl sulfonate, 26.75 parts of deionized water and 0.38 parts of hydrogen peroxide in reaction flask A, and heat Dissolve at 30°C-40°C and mix uniformly to obtain Polymer I.

[0061] (2) Under normal temperature conditions, 0.22 parts of ascorbic acid (VC), 0.22 parts of β-mercaptopropion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com