A mixed matrix membrane with high acid resistance for methane/nitrogen separation, its preparation method and application

A technology of mixed matrix membrane and methane, which is applied in the field of membrane separation, can solve problems such as inability to achieve separation, and achieve good acid stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

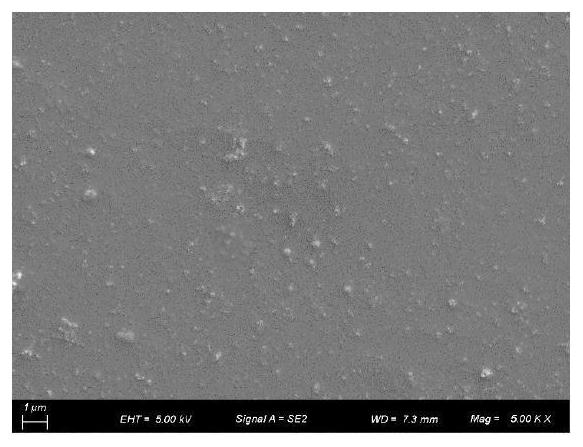

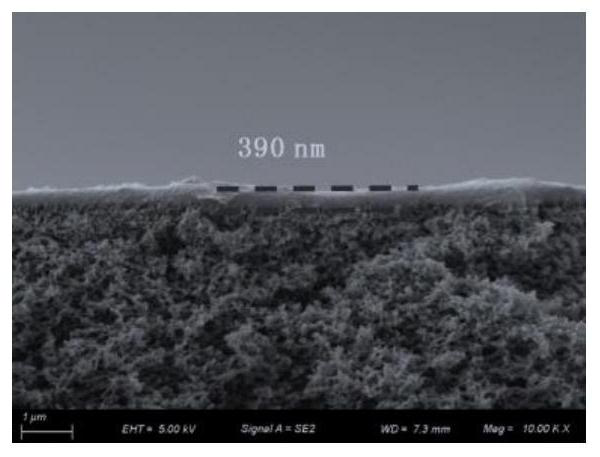

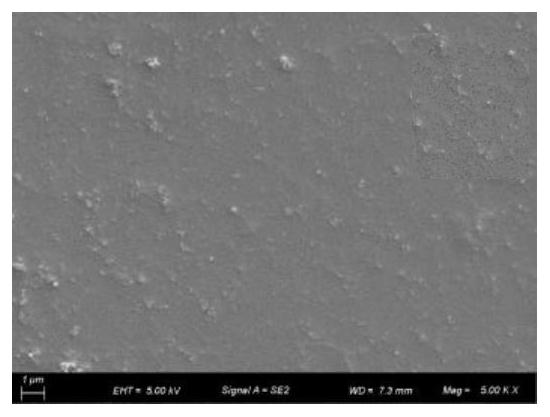

Image

Examples

preparation example 1

[0070] The preparation of ZIF-8 nanoparticles, concrete steps are as follows:

[0071] (1) Dissolve 2-methylimidazole and zinc nitrate 6-water in 100ml of methanol respectively to obtain a methanol solution of 2-methylimidazole with a concentration of 10g / L and 6-hydronic nitric acid with a concentration of 12g / L Methanol solution of zinc;

[0072] (2) Mix the methanol solution of 2-methylimidazole with a concentration of 10g / L and the methanol solution of zinc nitrate 6-water with a concentration of 12g / L obtained above, and let it stand for 24 hours, then use methanol to control the rotation speed to 300 Centrifugal cleaning at -500r / min until the effluent is clear, and then drying at a temperature of 80°C to obtain ZIF-8 nanoparticles with a particle size of 40-50nm;

[0073] The amount of the methanol solution of 2-methylimidazole and the methanol solution of zinc nitrate 6-water used in the above mixing is 3:1 according to the molar ratio of 2-methylimidazole:zinc nitrat...

preparation example 2

[0075] The preparation of ZIF-8 nanoparticles, concrete steps are as follows:

[0076] (1) Dissolve 2-methylimidazole and 6-zinc nitrate in methanol respectively to obtain a methanol solution of 2-methylimidazole with a concentration of 14g / L and a 6-zinc nitrate with a concentration of 12g / L methanol solution;

[0077] (2) Mix the methanol solution of 2-methylimidazole with a concentration of 14g / L and the methanol solution of zinc nitrate 6-water with a concentration of 12g / L obtained above, and let it stand for 24 hours to control the rotation speed to 300 with methanol Centrifugal cleaning at -500r / min until the effluent is clear, and then drying at a temperature of 80°C to obtain ZIF-8 nanoparticles with a particle size of 40-50nm;

[0078] The amount of the methanol solution of 2-methylimidazole and the methanol solution of zinc nitrate 6-water used in the above mixing is 3.11:1 according to the molar ratio of 2-methylimidazole:zinc nitrate 6-water.

preparation example 3

[0080] The preparation of ZIF-8 nanoparticles, concrete steps are as follows:

[0081] (1) Dissolve 2-methylimidazole and zinc nitrate 6-water in methanol respectively to obtain a methanol solution of 2-methylimidazole with a concentration of 14.69g / L and a 6-water nitric acid with a concentration of 16.24g / L Methanol solution of zinc;

[0082] (2) Mix the methanol solution of 2-methylimidazole with a concentration of 14.69g / L and the methanol solution of zinc nitrate 6-water with a concentration of 16.24g / L obtained above, and let it stand for 24 hours to control the rotation speed with methanol Centrifugal cleaning at 300-500r / min until the effluent is clear, and then drying at a temperature of 80°C to obtain ZIF-8 nanoparticles with a particle size of 40-50nm;

[0083] The amount of the methanol solution of 2-methylimidazole and the methanol solution of zinc nitrate 6-water used in the above mixing is 4:1 according to the molar ratio of 2-methylimidazole:zinc nitrate 6-wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com