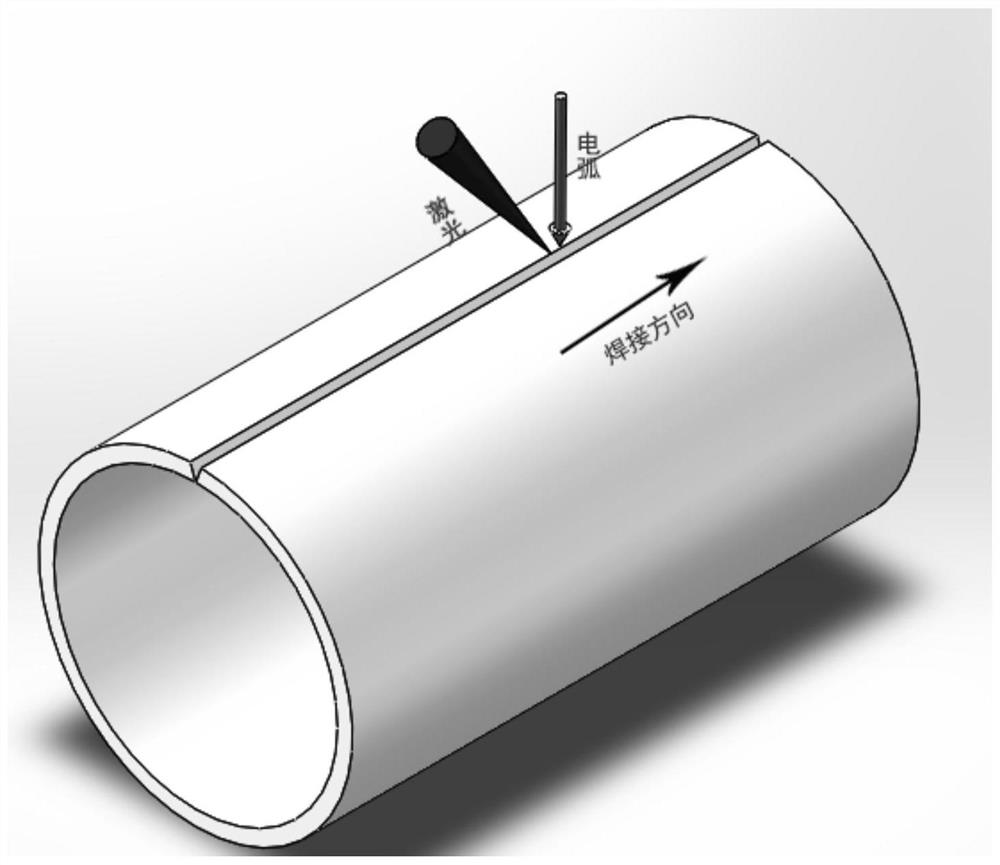

Efficient laser-electric arc composite heat source high-strength steel pipeline straight seam welding process

A compound heat source and straight seam welding technology, which is applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of expanding the heat-affected zone, reducing the mechanical properties, and unstable production quality. The effects of saving welding filler materials, improving welding production efficiency, and shortening the construction period of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

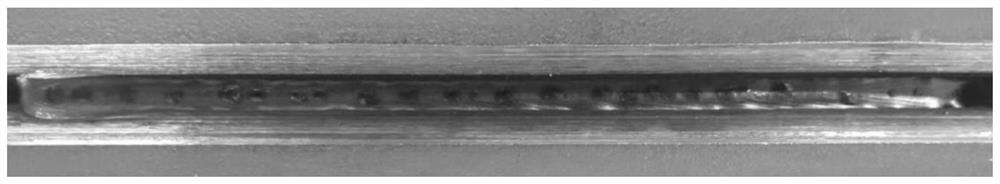

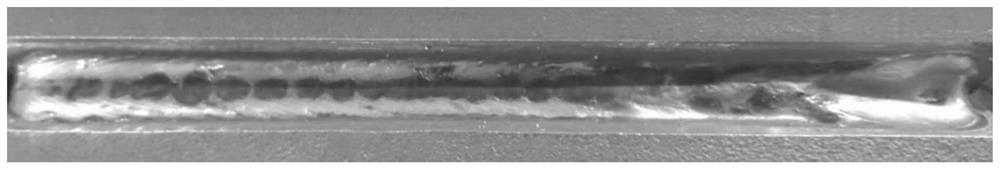

[0051] Example 1: Straight weld seam of X65 pipeline with wall thickness 16mm and pipeline inner diameter φ568

[0052] 1. Preparation before welding

[0053] (1) Groove processing, open a groove with 20° on both sides and 2mm on the blunt side.

[0054] (2) Check whether the surface of the workpiece is wet. If the surface of the workpiece is wet, wait for it to dry before welding;

[0055] (3) Grind the welded part with an angle grinder or sandpaper to remove surface oxides and use acetone solution to wipe off the oil.

[0056] (4) Welding method and selection of welding materials, using laser-MAG arc hybrid welding as the main method for welding, 82% argon and 18% CO 2 Mixed gas, the welding wire is ER70S-G welding wire with a diameter of 1mm.

[0057] 2. Spot welding

[0058] (1) According to the structural size of the workpiece, the distance between spot welding is 200mm, the spot welding current is 150A, and the spot welding time is 2s.

[0059] (2) When spot welding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com