Copper nanowire loaded CoNi nanosheet electrocatalyst as well as preparation method and application thereof

A technology of copper nanowires and electrocatalysts, applied in the field of electrocatalysis, can solve the problems of affecting the stability of catalytically active electrodes, restricting large-scale applications, and easy shedding of samples, so as to facilitate material transmission and increase the transmission of ions and electrons , Improve the effect of electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Place copper foam in 2mol / L NaOH and 0.2mol / L (NH 4 ) 2 S 2 o 8 Soak in the mixture solution for 20min, take it out and rinse to get Cu(OH) 2 Nanowires. Then placed in 1mol / L Na 2 SO 4 The current density in the solution is -20mA / cm 2 , reduced by a constant current for 15 minutes, taken out, rinsed, and dried in a vacuum oven to obtain Cu nanowires. Then place the Cu nanowire electrode in 30mL concentration of 0.1mol / L CoCl 2 and 0.1mol / L NiCl 2 In the mixed solution, use cyclic voltammetry with a scanning range of 0.2 to -1.2V and a scanning speed of 25mV / s, scan 25 times, take it out, rinse it, and dry it in a vacuum oven at 60°C for 4 hours to obtain copper nanoparticles. Wire-supported CoNi nanosheet electrocatalysts.

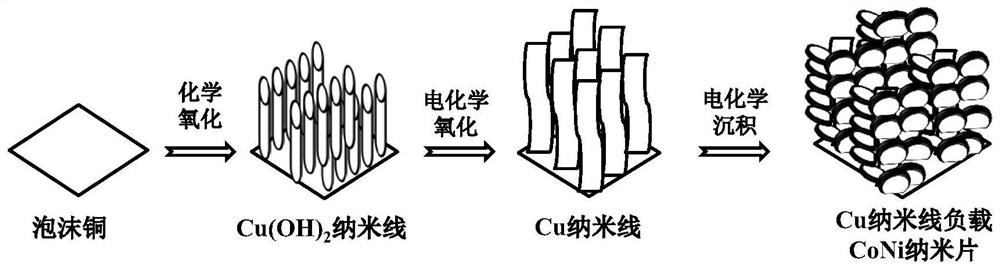

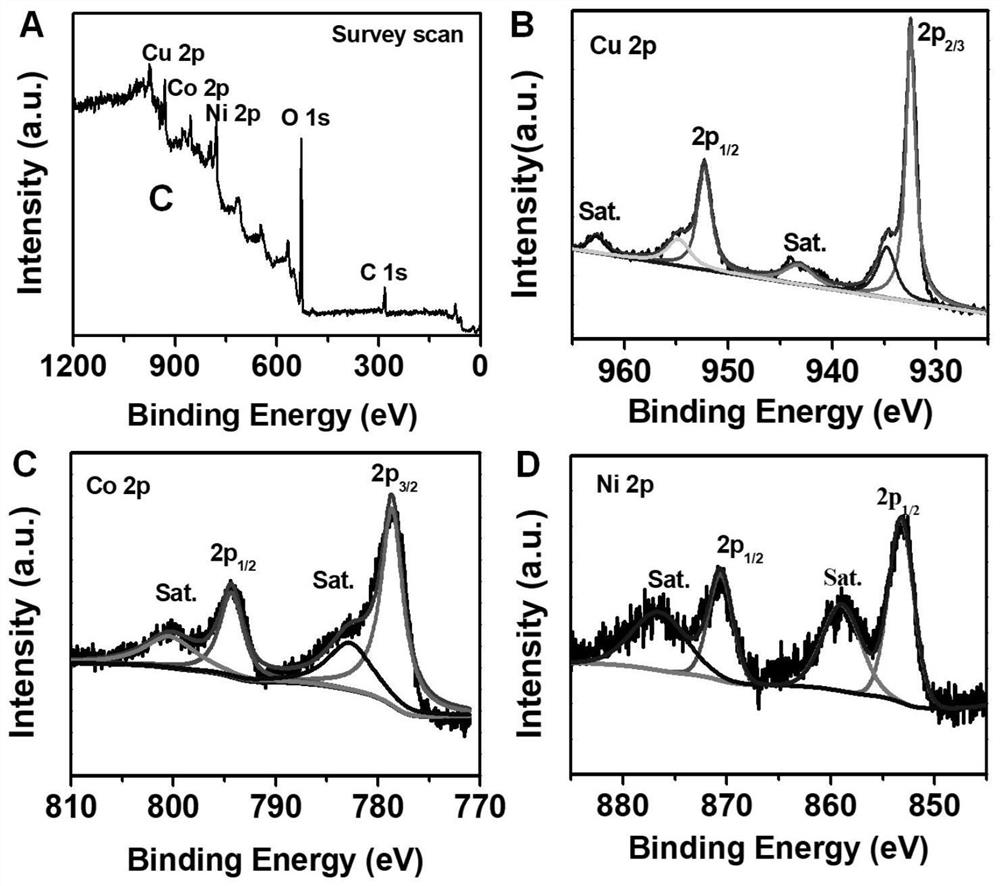

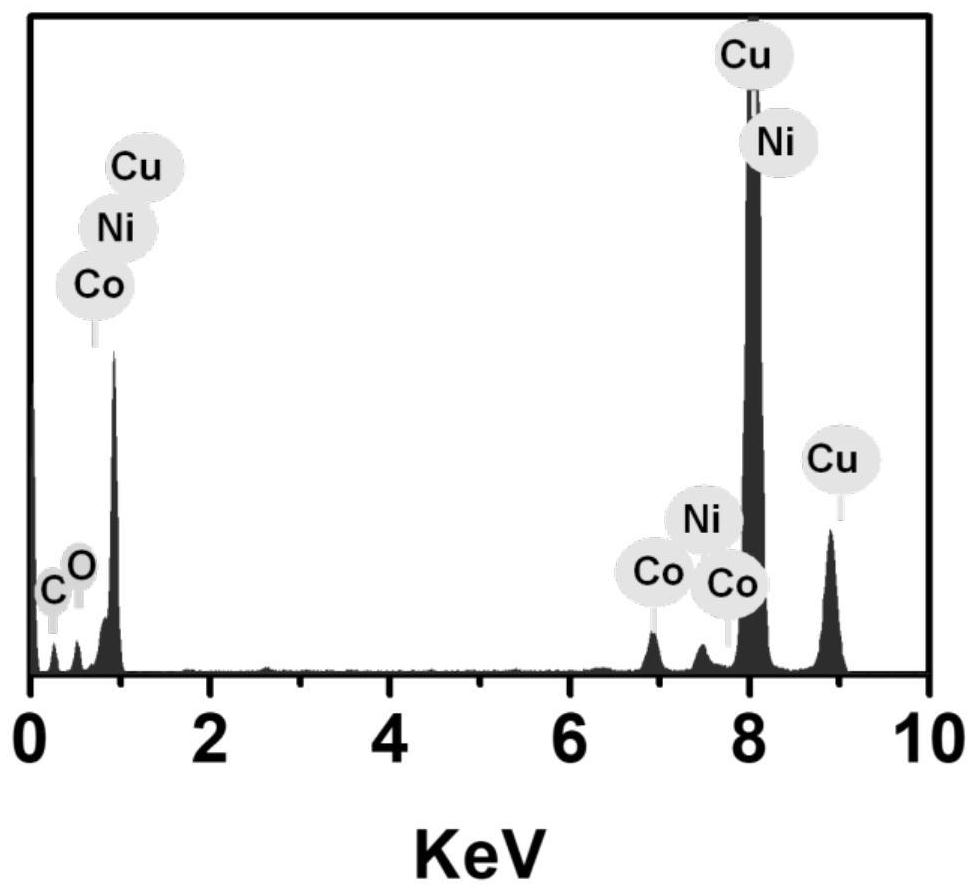

[0035] The schematic diagram of the preparation of CoNi nanosheet electrocatalyst supported by copper nanowires in this example is shown in figure 1 ; The prepared material is analyzed, copper nanowires loaded CoNi nanosheet electrocataly...

Embodiment 2

[0040] Place copper foam in 2mol / L NaOH and 0.2mol / L (NH 4 ) 2 S 2 o 8 Soak in the mixture solution for 20min, take it out and rinse to get Cu(OH) 2 Nanowires. Then placed in 1mol / L Na 2 SO 4 The current density in the solution is -20mA / cm 2 , reduced by a constant current for 15 minutes, taken out, rinsed, and dried in a vacuum oven to obtain Cu nanowires. Then place the Cu nanowire electrode in 30mL concentration of 0.1mol / L CoCl 2 and 0.1mol / L NiCl 2 In the mixed solution, use cyclic voltammetry with a scanning range of 0.2 to -1.2V and a scanning speed of 25mV / s, scan 5 times, take it out, rinse it, and dry it in a vacuum oven at 60°C for 4 hours to obtain copper nanowires Supported CoNi nanosheet electrocatalysts.

Embodiment 3

[0042] Place copper foam in 2mol / L NaOH and 0.2mol / L (NH 4 ) 2 S 2 o 8 Soak in the mixture solution for 20min, take it out and rinse to get Cu(OH) 2 Nanowires. Then placed in 1mol / L Na 2 SO 4 The current density in the solution is -20mA / cm 2 , reduced by a constant current for 15 minutes, taken out, rinsed, and dried in a vacuum oven to obtain Cu nanowires. Then place the Cu nanowire electrode in 30mL concentration of 0.1mol / L CoCl 2 and 0.1mol / L NiCl 2 In the mixed solution, use cyclic voltammetry with a scanning range of 0.2 to -1.2V and a scanning speed of 25mV / s, scan 50 times, take it out, rinse it, and dry it in a vacuum oven at 60°C for 4 hours to obtain copper nanowires Supported CoNi nanosheet electrocatalysts.

[0043] The difference between embodiment 1 and embodiment 2 and embodiment 3 is that the number of scanning circles is different, adopt the same experimental method as embodiment 1 to the performance verification of embodiment 2-3 product, the resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com