Fireproof and explosion-proof power cable and preparation method thereof

A technology for power cables and cable cores, applied in the field of fireproof and explosion-proof power cables and their preparation, can solve problems such as fires and secondary disasters, achieve the effects of eliminating explosions, preventing static sparks, and improving physical and mechanical properties and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

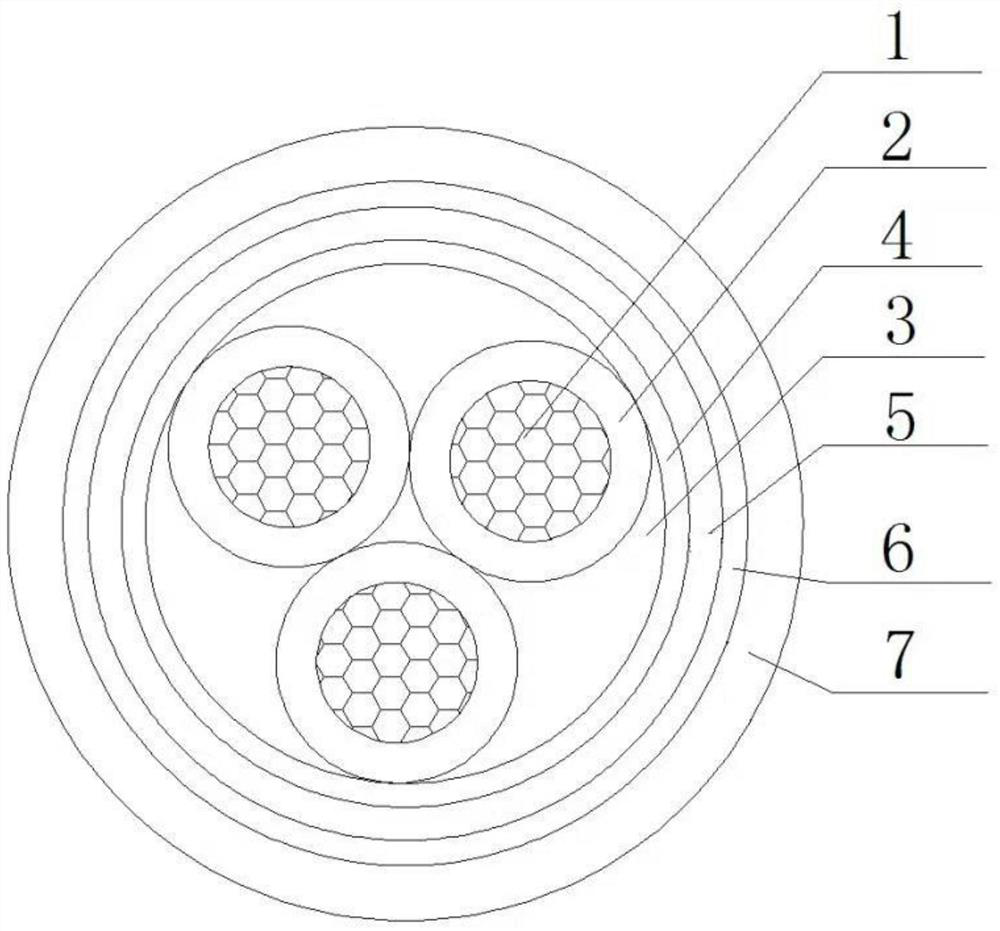

[0042] refer to figure 1 , A fire-proof and explosion-proof power cable proposed by the present invention includes: a cable core, an outer insulating layer 4 wrapped around the outside of the cable core, an inner sheath 5 longitudinally wrapped outside the outer insulating layer 4, and an inner sheath 5 wrapped around The outer high temperature cladding layer 6 and the outer sheath 7 extruded and wrapped outside the high temperature cladding layer 6;

[0043]The cable core includes a plurality of conductors 1 and an inner insulating layer 2 wrapped around the outside of the conductor 1; the conductor 1 is formed by twisting and pressing a plurality of copper wires; the inner insulating layer 2 adopts an inorganic refractory synthetic mica tape. It is formed by wrapping and drying; the gap in the cable core is filled with inorganic refractory filling material 3 magnesium hydroxide;

[0044] The outer insulating layer 4 is made of inorganic refractory synthetic mica tape wrappe...

Embodiment 2

[0062] Compared with Example 1, the raw material ratio of the chlorinated polyethylene rubber sheathing material is different, and the details are as follows:

[0063] The raw materials of the chlorinated polyethylene rubber sheathing material, in parts by weight, include: 90 parts of chlorinated polyethylene resin, 10 parts of EPDM rubber, 20 parts of acetylene carbon black, 40 parts of graphite powder, and 20 parts of nano aluminum hydroxide , 1 part of antioxidant, 2.8 parts of organic peroxide, 3 parts of accelerator, 1 part of coupling agent KH560, 5 parts of magnesium oxide, 20 parts of processing oil, 4 parts of other additives;

[0064] Among them, the nano aluminum hydroxide is an aluminate coupling agent modified nano aluminum hydroxide, and its preparation is as follows: adding the anhydrous ethanol solution of the aluminate coupling agent into the nano aluminum hydroxide, and stirring the reaction at 40 ° C 6h, centrifuge, wash, dry, grind, and obtain; wherein, the...

Embodiment 3

[0066] Compared with Example 1, the raw material ratio of the chlorinated polyethylene rubber sheathing material is different, and the details are as follows:

[0067] The raw materials of the chlorinated polyethylene rubber sheathing material, in parts by weight, include: 90 parts of chlorinated polyethylene resin, 10 parts of EPDM rubber, 30 parts of acetylene carbon black, 20 parts of graphite powder, and 30 parts of nano aluminum hydroxide , 2 parts of antioxidant, 4.2 parts of organic peroxide, 4 parts of accelerator, 2 parts of coupling agent KH560, 15 parts of magnesium oxide, 30 parts of processing oil, 6 parts of other additives;

[0068] Among them, the nano aluminum hydroxide is an aluminate coupling agent modified nano aluminum hydroxide, and its preparation is as follows: adding the anhydrous ethanol solution of the aluminate coupling agent into the nano aluminum hydroxide, and stirring the reaction at 50 ° C 4h, centrifuge, wash, dry, grind, and obtain; wherein, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus of rupture | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com