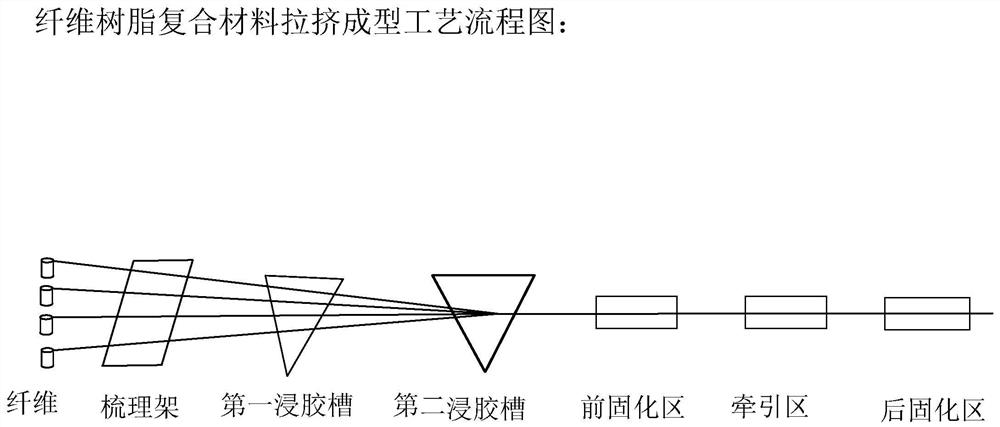

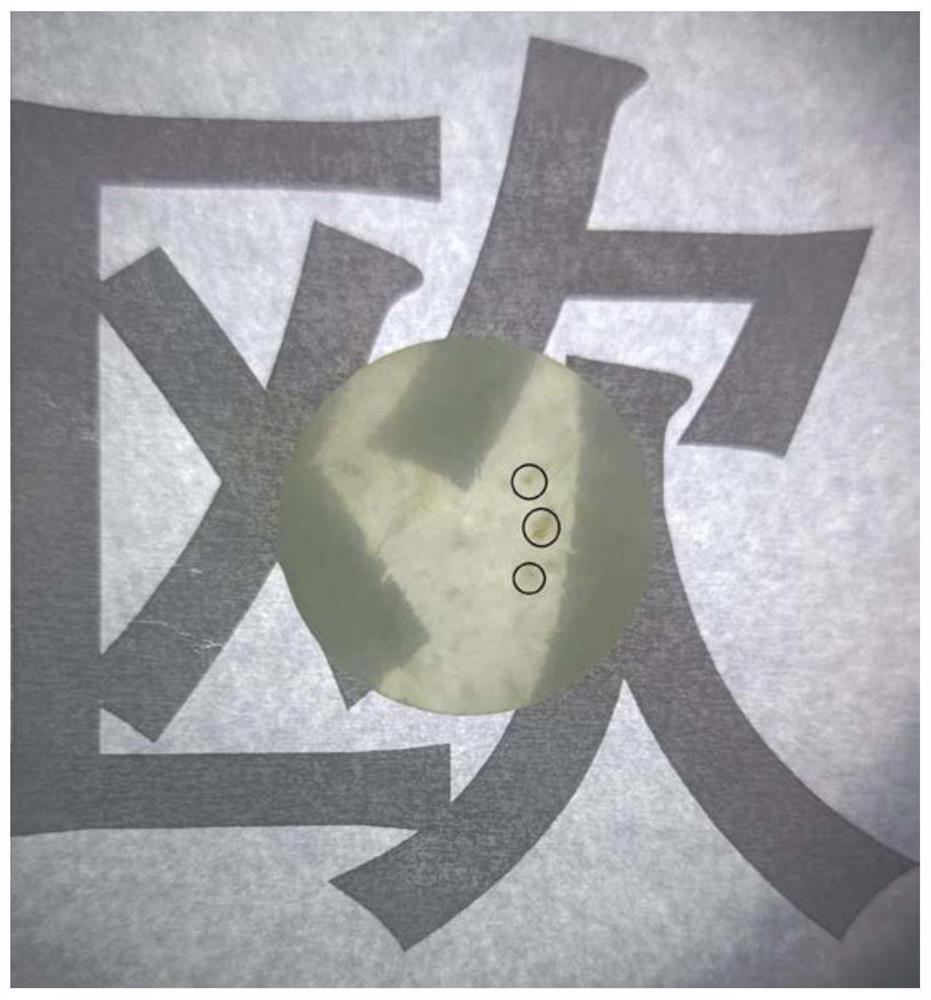

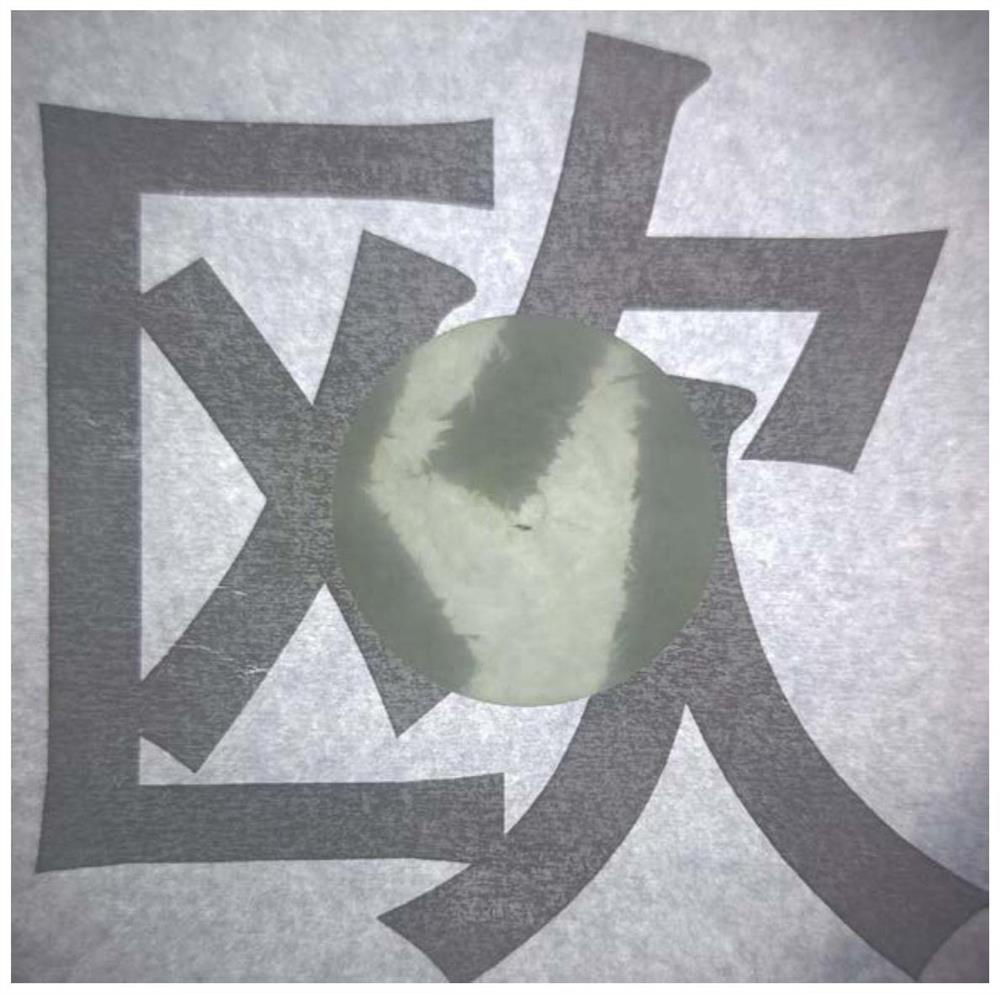

High-light-transmittance fiber resin composite material for repairing peg, core and crown of machinable dental department and preparation method

A technology of fiber resin and composite materials, applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve the problem of being unable to observe restorations, difficult to meet the requirements of CAD/CAM design and cutting, and having no X-ray resistance and transparency. Light and other issues, to achieve the effect of good aesthetics, small deformation, high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0074] Put 5.0kg of epoxy resin, 4.7kg of methyl tetrahydrophthalic anhydride, 1.5kg of DMP-30, 0.2kg of internal mold release agent, 0.1kg of antioxidant 1010 and 2.0kg of barium glass powder into the mixer, and use 600r / Stir at a stirring rate of 90 min for 90 min to obtain a resin matrix 1 with a refractive index of 1.57.

preparation example 2

[0076] Put 5.0kg of epoxy resin, 4.7kg of methyl hexahydrophthalic anhydride, 1.5kg of DMP-30, 0.2kg of internal mold release agent, 0.1kg of antioxidant 1010 and 2.0kg of barium glass powder into the mixer, and use 600r / Stir at a stirring rate of 90 min for 90 min to obtain a resin matrix 2 with a refractive index of 1.58.

preparation example 3

[0078] Put 6.8kg of epoxy resin, 3.5kg of methyl hexahydrophthalic anhydride, 1.5kg of DMP-30, 0.2kg of internal mold release agent, 0.1kg of antioxidant 1010 and 2.0kg of barium glass powder into the mixer, and use 600r / The mixture was stirred at a stirring rate of 90 min for 90 min to obtain a resin matrix 3 with a refractive index of 1.56.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com