Method for producing glucose through enzymolysis of poplar

A glucose and enzymatic hydrolysis technology, which is applied in the field of poplar wood enzymatic hydrolysis to produce glucose, can solve the problems of long enzymatic hydrolysis time, large amount of cellulase, and shortened enzymatic hydrolysis time, so as to reduce the amount of enzyme, increase the yield of glucose, shorten The effect of enzymatic digestion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

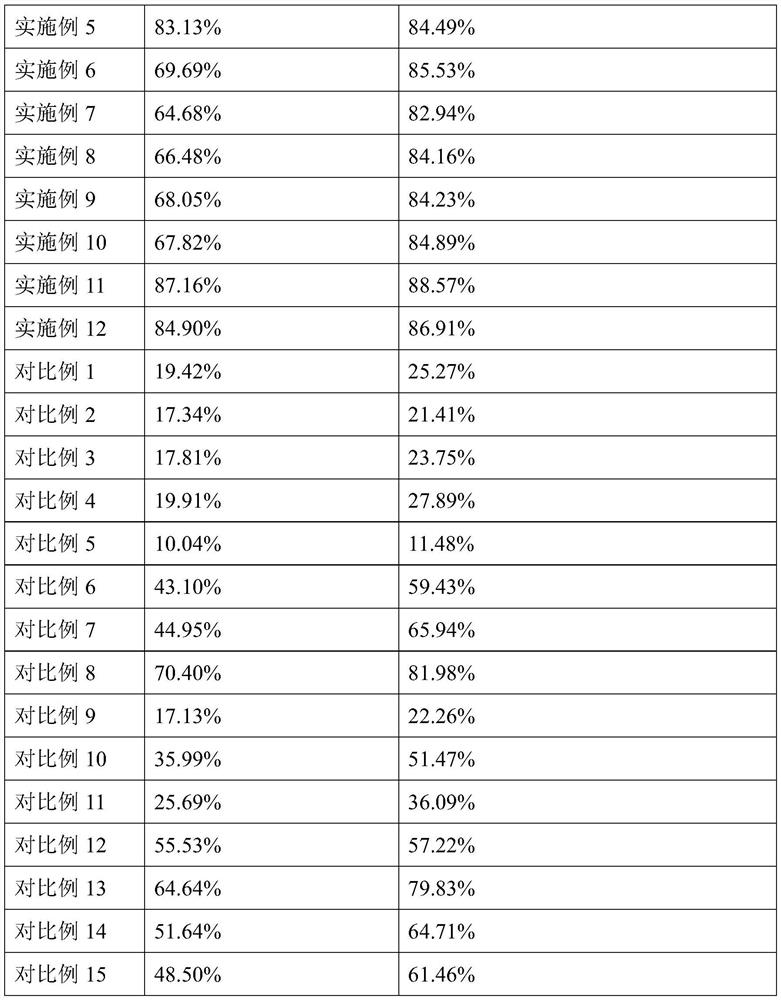

Examples

Embodiment 1

[0034] Embodiment 1 A kind of method that improves poplar enzymatic hydrolysis efficiency

[0035] S1. poplar wood pretreatment: 12g (absolute dry weight) poplar wood and 0.80g AlCl 3 Add 120mL of ultra-pure water, react in the reaction kettle at 180°C and 300rpm for 20min, add deionized water to wash until neutral, and use vacuum filtration to obtain poplar wood pretreatment residue;

[0036] S2. Enzymolysis: Take 2g poplar wood pretreatment residue (dry quantity), add 100mL acetic acid-sodium acetate buffer solution with pH=4.8, 40FPU cellulase (Saili II) and 0.3g surfactant PEG 8000, Enzyme hydrolyze at 50°C with a rotational speed of 150rpm.

Embodiment 2

[0037] Embodiment 2 A kind of method that improves poplar enzymatic hydrolysis efficiency

[0038] The difference from Example 1 is that the surfactant is replaced with 0.8 g of whey protein, and 100 mL of acetic acid-sodium acetate buffer solution with pH=4.5 is added.

Embodiment 3

[0039] Example 3 A method for improving the efficiency of enzymatic hydrolysis of poplar

[0040] The difference from Example 1 is that the surfactant is replaced by 0.2 g of calcium lignosulfonate, and 100 mL of acetic acid-sodium acetate buffer solution with pH=5 is added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com