Neodymium-iron-boron magnetic powder and preparation method thereof

A neodymium iron boron and magnetic powder technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., to avoid local demagnetization effect, reduce the probability of magnetic powder oxidation, and achieve the effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A novel method for preparing NdFeB magnetic powder, the specific steps are as follows:

[0038] 1. Ingredients smelting, smelting Nd-Fe-B alloy ingots or quick-setting sheets, the mass percentage of Nd, Fe, and B is as follows: Nd: 26.8%, B: 1.1%, and the rest is Fe. The melting process is quick-setting, smelting Argon protection during the process.

[0039] 2. Coarse crushing is convenient for the subsequent smelting process of the rapid quenching and spinning belt. The ingot or quick-setting sheet prepared in step 1 is broken into fine particles with a particle size of 13-48mm. The crushing equipment is a jaw crusher.

[0040] 3. Rapid quenching and stripping to obtain amorphous NdFeB thin strips. Add the coarsely crushed magnetic powder in step 2 to an induction furnace under argon protection for melting, and then perform rapid quenching and stripping treatment to obtain amorphous thin strips. bring.

[0041] 4. Tempering treatment to improve the homogenization of ...

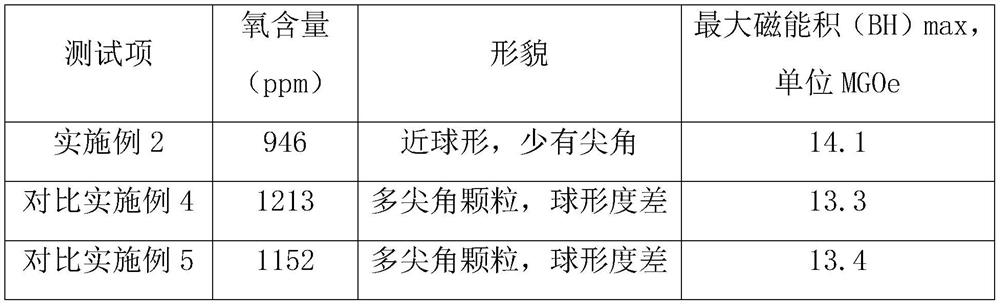

Embodiment 2

[0056] A novel method for preparing NdFeB magnetic powder, the specific steps are as follows:

[0057] 1. Ingredients smelting, smelting Nd-Fe-B alloy ingots or quick-setting sheets, Nd, Fe, and B mass percentages are Nd: 27.2%, B: 1.24%, and the rest is Fe. The smelting process is quick-setting, and the smelting process Medium argon protection.

[0058] 2. Coarse crushing is convenient for the subsequent smelting process of the rapid quenching and spinning belt. The ingot or quick-setting sheet prepared in step 1 is broken into fine particles with a particle size of 15-49mm. The crushing equipment is a jaw crusher.

[0059] 3. Rapid quenching and stripping to obtain amorphous NdFeB thin strips. Add the coarsely crushed magnetic powder in step 2 to an induction furnace under argon protection for melting, and then perform rapid quenching and stripping treatment to obtain amorphous thin strips. bring.

[0060] 4. Tempering treatment to improve the homogenization of the amorpho...

Embodiment 3

[0075] A novel method for preparing NdFeB magnetic powder, the specific steps are as follows:

[0076] 1. Ingredients smelting, smelting Nd-Fe-B alloy ingots or quick-setting sheets, the mass percentage of Nd, Fe, and B is as follows: Nd: 28.2%, B: 1.3%, and the rest is Fe. The smelting process is quick-setting, smelting Argon protection during the process.

[0077] 2. Coarse crushing is convenient for the subsequent smelting process of the quick quenching and spinning belt. The ingot or quick-setting sheet prepared in step 1 is broken into fine particles with a particle size of 11-39mm. The crushing equipment is a jaw crusher.

[0078] 3. Rapid quenching and stripping to obtain amorphous NdFeB thin strips. Add the coarsely crushed magnetic powder in step 2 to an induction furnace under argon protection for melting, and then perform rapid quenching and stripping treatment to obtain amorphous thin strips. bring.

[0079] 4. Tempering treatment to improve the homogenization of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com