Preparation method and application of active layer of organic photovoltaic device

A technology of organic photovoltaic devices and active layers, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, and electric solid-state devices. The effect of thin film morphology and performance, short preparation cycle and low preparation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Weigh 8.2 mg of polymer donor PM6 and dissolve it in 1 ml of chloroform solvent to obtain a PM6 solution with a concentration of 8.2 mg / ml;

[0035] 2) Weighing 8 mg of the small molecule receptor Y6 solution and dissolving it in 1 ml of chloroform solvent to obtain a Y6 solution with a concentration of 8 mg / ml;

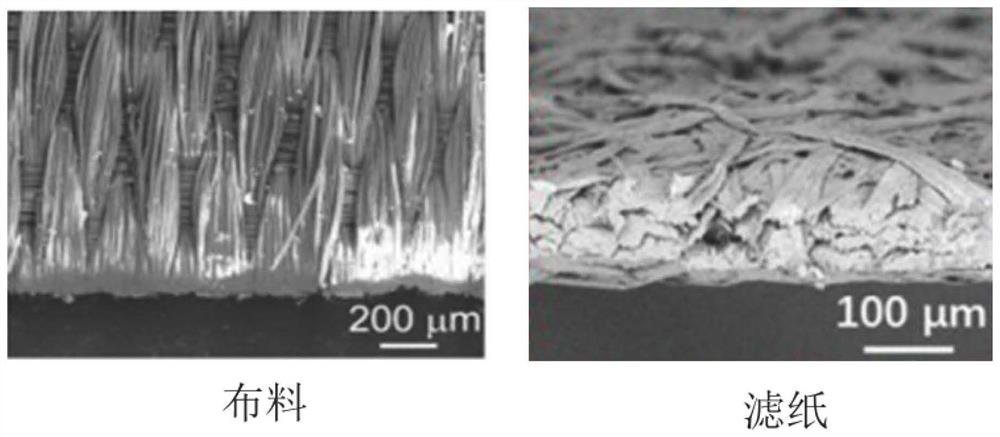

[0036] 3) Prepare several filter paper scrapers with a width of 1 cm;

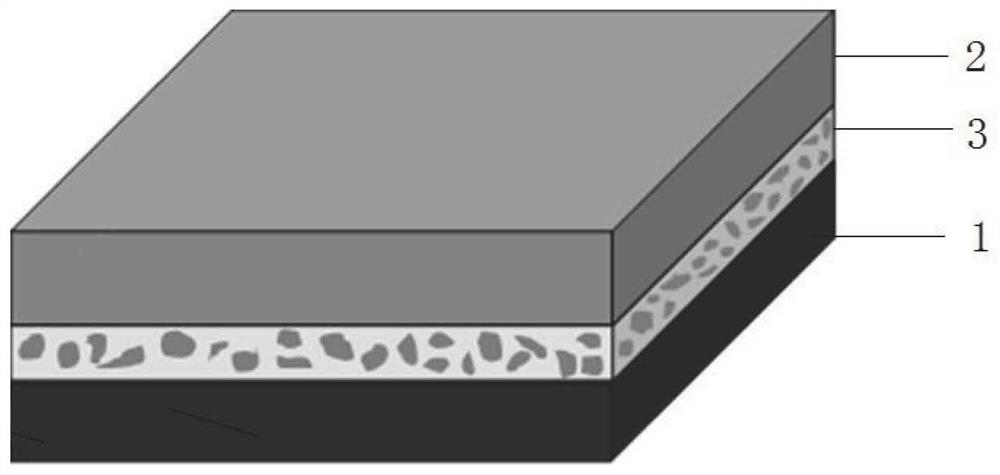

[0037] 4) Prepare PEDOT:PSS film layer on the cleaned ITO substrate;

[0038] 5) Scrape PM6 solution on the PEDOT:PSS layer, adjust the contact between the scraper and the substrate, the liquid supply flow rate is 15 μl / min, and the scraping speed is 3mm / s;

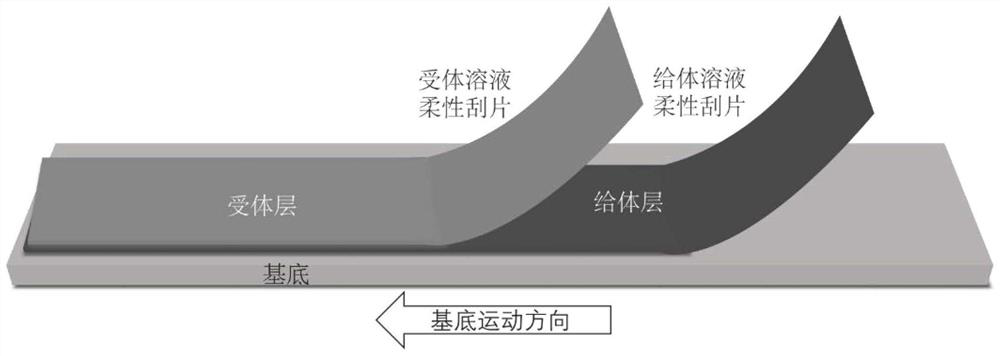

[0039] 6) Replace the scraper, continue to scrape the Y6 solution on the donor PM6 layer, adjust the contact between the scraper and the substrate, the flow rate of the liquid supply is 10 μl / min, and the scraping speed is 2mm / s, and finally a planar diffusion heterojunction organic active layer.

[0040] 7) Prepare the electron...

Embodiment 2

[0043] 1) Weigh 5 mg of polymer donor PTQ10 and dissolve it in 1 ml of chloroform / o-xylene mixed solvent to obtain a PTQ10 solution with a concentration of 5 mg / ml;

[0044] 2) Weighing 6 mg of the small molecule receptor Y6-BO and dissolving it in 1 ml of chloroform / o-xylene mixed solvent to obtain a Y6-BO solution with a concentration of 6 mg / ml;

[0045] 3) Prepare several flexible microstructure cloth scrapers with a width of 1 cm;

[0046] 4) Prepare PEDOT:PSS film layer on the cleaned ITO substrate;

[0047] 5) Scrape-coat PTQ10 solution on the PEDOT:PSS layer, adjust the contact between the scraper and the substrate, the substrate temperature is 70°C, and the scraping speed is 25mm / s;

[0048] 6) Replace the scraper, continue to scrape the Y6-BO solution on the donor PTQ10 layer, adjust the contact between the scraper and the substrate, the substrate temperature is 70°C, and the scraping speed is 35mm / s, and finally a planar diffusion heterojunction organic active lay...

Embodiment 3

[0053] Embodiment 3 is the same as the preparation method of the active layer and the organic solar cell device prepared from this active layer in embodiment 2, and the difference is that in step 1) and step 2), the donor and acceptor materials are independently adjacent Xylene solvent is dissolved, and concrete step 1) and step 2) are as follows:

[0054] 1) Weigh 5 mg of polymer donor PTQ10 and dissolve it in 1 ml of o-xylene solvent to obtain a PTQ10 solution with a concentration of 5 mg / ml;

[0055] 2) Weighing 6 mg of the small molecule receptor Y6-BO and dissolving it in 1 ml of o-xylene solvent to obtain a Y6-BO solution with a concentration of 6 mg / ml;

[0056] Step 3)-step 8) in this embodiment are exactly the same as Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com