Preparation method of infant rice flour with functions of quick solubility and easy digestion

A technology for infants and rice noodles, applied in food drying, food science, etc., can solve problems affecting product preparation, dissolution and rehydration performance, poor preparation performance of rice noodles, and unfavorable infants and young children to eat, etc., to increase digestion and absorption Functional, good heat retention, improved dissolution and rehydration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A kind of preparation method of quick-dissolving, easy-to-digest rice flour for infants and young children, it comprises the following steps:

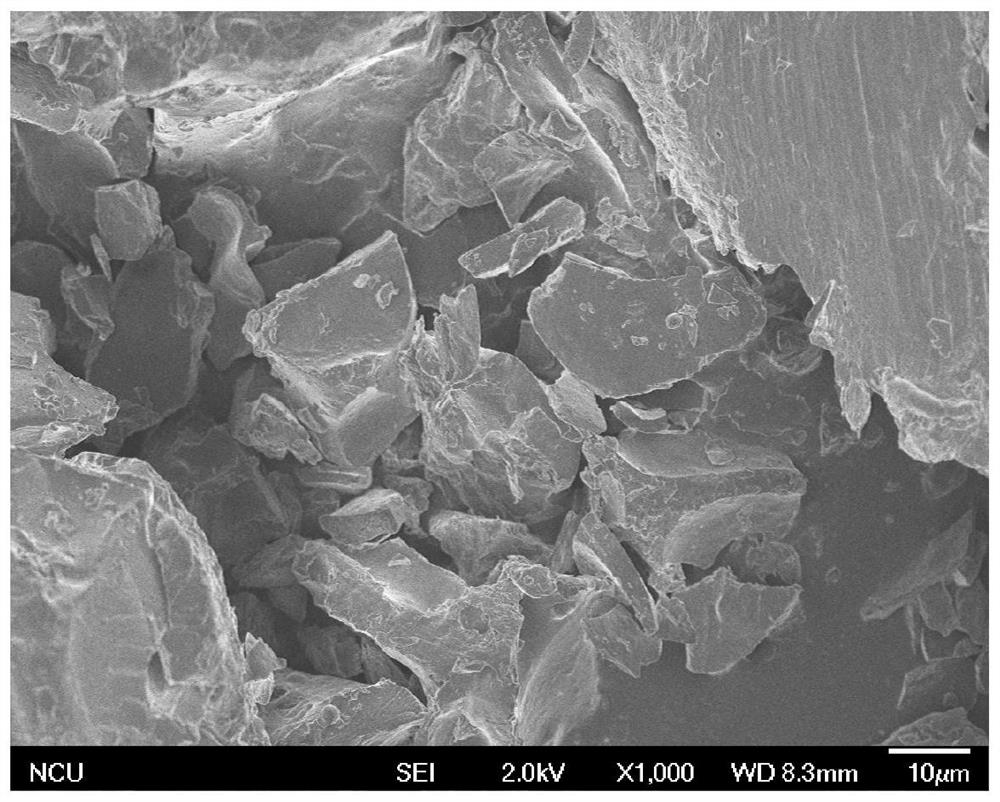

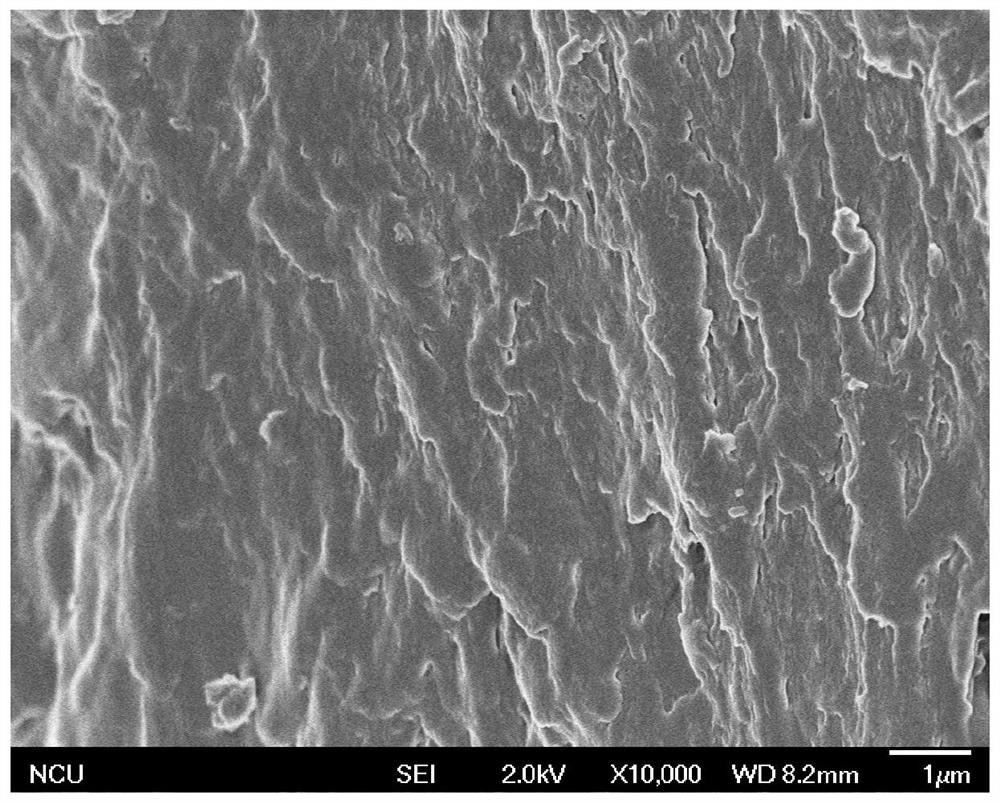

[0041] Step 1, pulping: crush the raw rice and pass it through a 60-100 mesh sieve, add water at 38-55°C to make the pulping, dissolve and mix evenly, and prepare rice with a concentration of 15-20% by mass of rice flour in the mixture Slurry, and then go through the colloid mill twice to get the slurry, the particle size after refining is 10-20μm;

[0042] Step 2, enzymatic hydrolysis: adding 0.10-0.15% high-temperature-resistant α-amylase of raw material rice flour and 0.10-0.13% enzyme activity accelerator of raw material rice flour into the refining liquid obtained in step 1 for enzymolysis, the temperature Enzymolysis at 80-90°C for 30-60 minutes, after enzymolysis, measure the DE value, inactivate the enzyme, and obtain the enzymolysis solution; the enzyme activity accelerator is CaCl 2 , CaSO 4 、Na 2 HPO 4 , Ca(NO 3 ...

Embodiment 1

[0065] A kind of preparation method of quick-dissolving, easy-to-digest rice flour for infants and young children, it comprises the following steps:

[0066] Step 1, pulping: crush the raw rice and pass it through a 60-mesh sieve, add water at 38°C for pulping, dissolve and mix evenly, and make rice pulp with a concentration of 15% of the mass percentage of rice flour in the mixture, and then pass it twice Colloid mill to obtain a refining solution, the particle size after refining is 10 μm;

[0067] Step 2, enzymatic hydrolysis: the high temperature resistant α-amylase of raw material rice flour 0.10% and the enzyme activity accelerator CaCl of raw material rice flour 0.10% 2 Add it to the refining solution obtained in step 1 for enzymolysis, enzymolysis at a temperature of 85°C for 46 minutes, measure the DE value after enzymolysis, and inactivate the enzyme to obtain an enzymolysis solution;

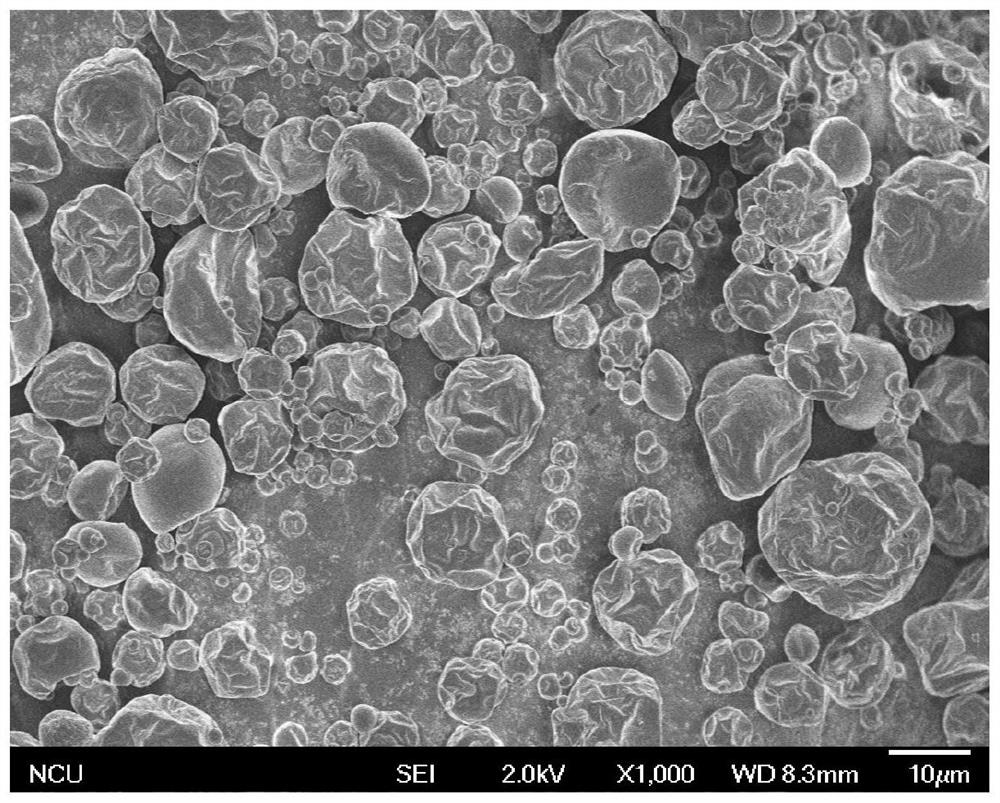

[0068] Step 3, spray drying: spray-dry the enzymolysis solution obtained in step...

Embodiment 2

[0071] A kind of preparation method of quick-dissolving, easy-to-digest rice flour for infants and young children, it comprises the following steps:

[0072] Step 1, pulping: crush the raw rice and pass through an 80-mesh sieve, add water at 45°C for pulping, dissolve and mix evenly, and make rice pulp with a concentration of 18% of the mass percentage of rice flour in the mixture, and then pass it twice Colloid mill to obtain a refining solution, the particle size after refining is 15 μm;

[0073] Step 2, enzymatic hydrolysis: the high temperature resistant α-amylase of raw material rice flour weight 0.13% and the enzyme activity accelerator CaSO of raw material rice flour weight 0.11% 4 Add it to the refining solution obtained in step 1 for enzymolysis, enzymolysis at 80°C for 60 minutes, measure the DE value after enzymolysis, and inactivate the enzyme to obtain an enzymolysis solution;

[0074] Step 3, spray drying: spray-dry the enzymolysis solution obtained in step 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com