A kind of in-situ regeneration method of catalyst for producing acetonitrile by ammoniation of acetic acid

A technology of ammonification and in-situ regeneration of acetic acid, which is applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems of insufficient combustion of catalyst carbon deposits, easy sintering of catalysts, and successful regeneration of catalysts Low efficiency and other problems, to achieve the effect of effective regeneration and reuse, saving labor in time, and meeting the requirements of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

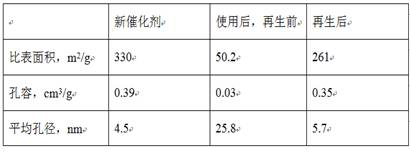

Embodiment 1

[0041] An in-situ regeneration method for a catalyst used in the process of producing acetonitrile by ammoniation of acetic acid comprises the steps of preparing a pretreatment solution, catalyst pretreatment, ultrasonic treatment, airflow contact treatment, oxidation calcining treatment, and secondary pore-forming treatment.

[0042] To configure the pretreatment solution, mix a predetermined number of N-methylpyrrolidone, acetonitrile, and water, and stir and mix at 200 RPM for 5 minutes to prepare the pretreatment solution.

[0043] The weight ratio of the N-methylpyrrolidone, acetonitrile and water is 30:90:10.

[0044] The acetonitrile has a purity greater than 99.9%, an ultraviolet light transmittance of 92% at UV200nm, 97% at 230nm, and 99% at 240nm.

[0045] The N-methylpyrrolidone has a purity greater than 99.9%, a moisture content of less than 0.02, a chromaticity of 12, and an electrical conductivity of 1.33×10 -8 s / m.

[0046] Described water is fresh water.

[...

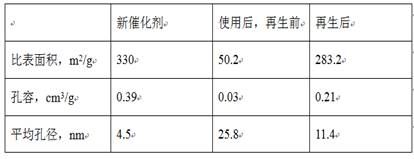

Embodiment 2

[0059] An in-situ regeneration method for a catalyst used in the process of producing acetonitrile by ammoniation of acetic acid comprises the steps of preparing a pretreatment solution, catalyst pretreatment, ultrasonic treatment, airflow contact treatment, oxidation calcining treatment, and secondary pore-forming treatment.

[0060] To prepare the pretreatment solution, mix a predetermined number of N-methylpyrrolidone, acetonitrile, and water, and stir and mix at 250 RPM for 10 minutes to prepare the pretreatment solution.

[0061] The weight ratio of the N-methylpyrrolidone, acetonitrile and water is 50:80:10.

[0062] The acetonitrile has a purity greater than 99.9%, an ultraviolet light transmittance of 92% at UV200nm, 97% at 230nm, and 99% at 240nm.

[0063] The N-methylpyrrolidone has a purity greater than 99.9%, a moisture content of less than 0.02, a chromaticity of 12, and an electrical conductivity of 1.33×10 -8 s / m.

[0064] Described water is fresh water.

[0...

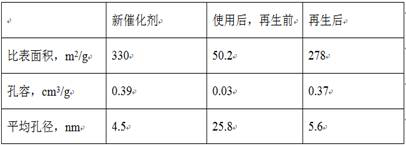

Embodiment 3

[0077] An in-situ regeneration method for a catalyst used in the process of producing acetonitrile by ammoniation of acetic acid comprises the steps of preparing a pretreatment solution, catalyst pretreatment, ultrasonic treatment, airflow contact treatment, oxidation calcining treatment, and secondary pore-forming treatment.

[0078] To configure the pretreatment solution, mix a predetermined number of N-methylpyrrolidone, acetonitrile, and water, and stir and mix at 300 RPM for 10 minutes to prepare the pretreatment solution.

[0079] The weight ratio of the N-methylpyrrolidone, acetonitrile and water is 50:85:20.

[0080] The acetonitrile has a purity greater than 99.9%, an ultraviolet light transmittance of 92% at UV200nm, 97% at 230nm, and 99% at 240nm.

[0081] The N-methylpyrrolidone has a purity greater than 99.9%, a moisture content of less than 0.02, a chromaticity of 12, and an electrical conductivity of 1.33×10 -8 s / m.

[0082] Described water is fresh water.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com