Synthesis method of tetrabutylammonium bromide

A technology of tetrabutylammonium bromide and synthesis method, applied in the field of tetrabutylammonium bromide synthesis, can solve problems such as increasing energy consumption, increasing equipment cost, large amount of solvent added, avoiding evaporation loss, improving color degree, the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

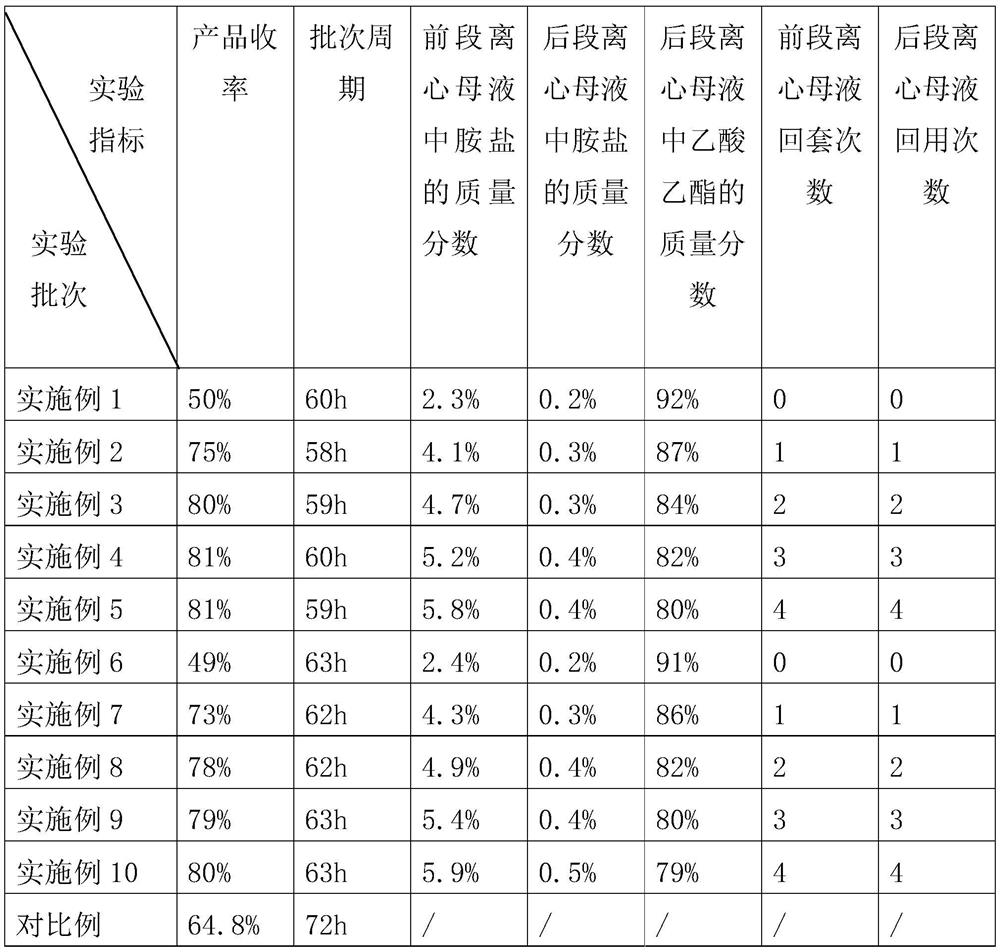

Examples

Embodiment 1

[0025] A kind of synthetic method of tetrabutylammonium bromide is characterized in that comprising the following steps:

[0026] (1) Prepare 640kg of dichloroethane solvent, 960kg of bromobutane and 1200kg of tri-n-butylamine to the corresponding batching tanks respectively, and add them to the reaction kettle in turn, and reflux at 95°C for 40 hours to obtain tetrabutyl Crude ammonium bromide;

[0027] (2) material in the reaction kettle is cooled to 60 ℃, and the tetrabutylammonium bromide crude product obtained in the step (1) is transferred in the crystallization kettle;

[0028] (3) Continue to lower the temperature of the crystallization kettle to 20°C for crystallization, and after the crystallization is completed, transfer the material to a centrifuge for centrifugation to obtain the centrifuged mother liquor in the previous stage;

[0029] (4) When the centrifuge no longer has mother liquor to flow out, rinse the centrifuge with 40kg ethyl acetate, centrifuge again ...

Embodiment 2

[0031] A kind of synthetic method of tetrabutylammonium bromide is characterized in that comprising the following steps:

[0032] (5) Detect the front-stage centrifugal mother liquor obtained in step (3) in Example 1, the mass fraction of amine salt is 2.3%, prepare the front-stage centrifugal mother liquor in the step (3) of Example 1 to the batching tank, and replenish inwardly Dichloroethane to 640kg, in addition, 960kg of bromobutane and 1200kg of tri-n-butylamine were respectively prepared into corresponding batching tanks, and added to the reaction kettle in turn, and refluxed at 95°C for 40h to obtain tetrabutyl bromide Crude ammonium;

[0033] (6) material in the reaction kettle is cooled to 60 ℃, and the tetrabutylammonium bromide crude product obtained in the step (5) is transferred in the crystallization kettle;

[0034] (7) Continue cooling the crystallization kettle to 20°C for crystallization, transfer to a centrifuge for centrifugation after the crystallization...

Embodiment 3

[0037] A kind of synthetic method of tetrabutylammonium bromide is characterized in that comprising the following steps:

[0038] (9) Detect the front-stage centrifugal mother liquor obtained in step (7) in Example 2, the mass fraction of amine salt is 4.1%, prepare the front-stage centrifugal mother liquor in the step (7) of Example 2 to the batching tank, and supplement inwardly Dichloroethane to 640kg, in addition, 960kg of bromobutane and 1200kg of tri-n-butylamine were respectively prepared into corresponding batching tanks, and added to the reaction kettle in turn, and refluxed at 95°C for 40h to obtain tetrabutyl bromide Crude ammonium;

[0039] (10) material in the reaction kettle is cooled to 60 ℃, and the tetrabutylammonium bromide crude product obtained in the step (9) is transferred in the crystallization kettle;

[0040] (11) Continue cooling the crystallization kettle to 20°C for crystallization, transfer to a centrifuge for centrifugation after the crystallizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com