High-conductivity antibacterial formaldehyde-free adhesive as well as preparation method and application thereof

A kind of aldehyde adhesive, high conductivity technology, applied in the field of highly conductive antibacterial aldehyde-free adhesive and its preparation, can solve the problem of release, achieve high dry strength and water resistance bonding performance, solve non-renewable problems, stable sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

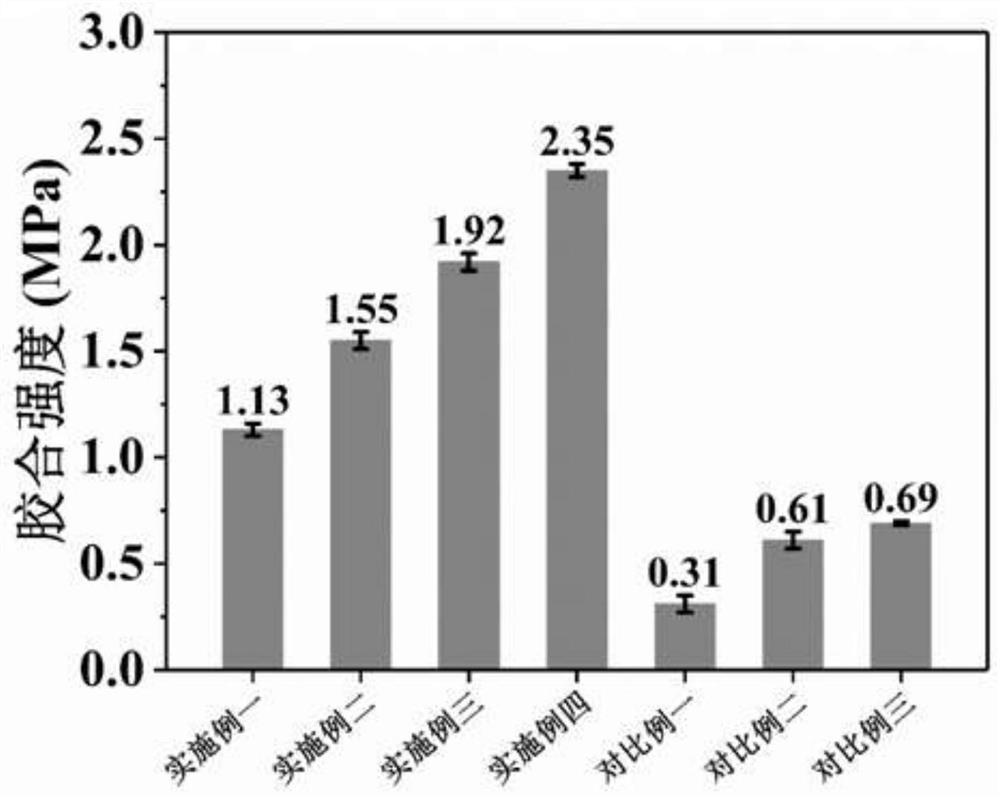

Examples

preparation example Construction

[0034] The preparation method of the barium titanate@silver nanoparticles, comprising the following steps:

[0035] a: Weigh 0.3g of barium titanate nanoparticles and add 90ml of SnCl 2 ·H 2 In the mixed solution of O and HCl, the SnCl 2 ·H 2 The concentration of O in the mixed solution is 0.05M, and the concentration of the HCl in the mixed solution is 0.02M. After stirring evenly, ultrasonically disperse for 30min, stir and reflux the mixed solution for centrifugation, and wash the precipitate with deionized water and then dry it;

[0036] b: ultrasonically disperse the precipitate obtained in step a in 60 ml of 0.35M silver nitrate ammonia water, stir for 30 min, and then centrifuge, and wash the precipitate with deionized water to obtain a granular product;

[0037] c: take another 45ml of 0.03M silver nitrate ammonia water, add 45ml of 0.25% polyvinylpyrrolidone, ultrasonically disperse the granular product obtained in step c in the above mixed solution, add 2ml of for...

Embodiment 1

[0039] A preparation method of a highly conductive antibacterial formaldehyde-free adhesive, comprising the following steps:

[0040] 1) Weigh 6g neopentyl glycol diglycidyl ether, two parts of 6g soybean protein powder, 88g dispersion medium water, 0.25g barium titanate@silver nanoparticles;

[0041] 2) Add neopentyl glycol diglycidyl ether, a portion of soybean protein powder and barium titanate@silver nanoparticles into the dispersion medium water in turn, and ultrasonically disperse for 10 min after stirring uniformly;

[0042] 3) Add another part of soybean protein powder into the mixed solution in step 2), stir evenly, and prepare a highly conductive and antibacterial formaldehyde-free adhesive.

Embodiment 2

[0044] A preparation method of a highly conductive antibacterial formaldehyde-free adhesive, comprising the following steps:

[0045] 1) Weigh 6g neopentyl glycol diglycidyl ether, two parts of 6g soybean protein powder, 88g dispersion medium water, 0.5g barium titanate@silver nanoparticles;

[0046]2) Add neopentyl glycol diglycidyl ether, a portion of soybean protein powder and barium titanate@silver nanoparticles into the dispersion medium water in turn, and ultrasonically disperse for 10 min after stirring uniformly;

[0047] 3) Add another part of soybean protein powder into the mixed solution in step 2), stir evenly, and prepare a highly conductive and antibacterial formaldehyde-free adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com