Preparation method of slice battery and laser equipment

A laser equipment and slicing technology, applied in the field of solar cells, can solve the problems of laser heat loss, efficiency loss, passivation defect loss at the cut surface, etc., so as to reduce the loss of total efficiency, reduce equipment occupation, and strengthen the passivation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

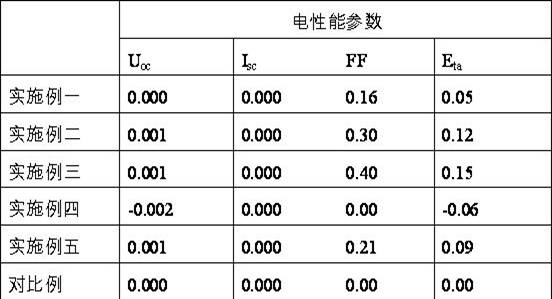

Examples

preparation example Construction

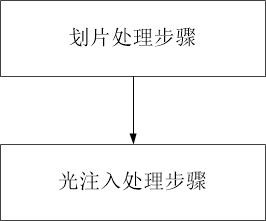

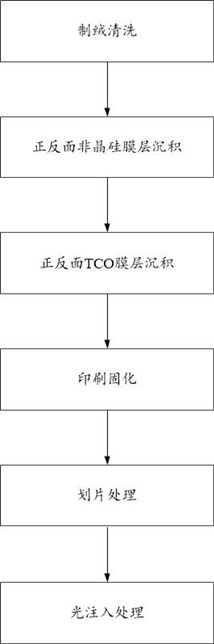

[0036] It can be understood that the preparation method of sliced cells generally includes multiple steps, and the scribing step and the light injection step are two of them. The preparation methods of different types of sliced cells are different. The preparation process of PERC sliced cells is It can include: texture cleaning, high temperature diffusion, etching and polishing, aluminum oxide film deposition on the back, silicon nitride film deposition on the front, laser grooving on the back, printing and sintering, light injection / electrical injection treatment, and scribing treatment. Taking the heterojunction battery as an example, its preparation method can include texture cleaning, front and back amorphous silicon film deposition, front and back TCO film deposition, printing and curing, light injection treatment and scribing treatment. However, in the embodiments of the present disclosure, only the light injection process and the scribing process are focused on, an...

Embodiment 1

[0050] see figure 2 For the embodiment of the present disclosure, a method for preparing a sliced battery is provided, the preparation method includes texture cleaning, front and back amorphous silicon film deposition, front and back TCO film deposition, printing and curing, dicing treatment and light injection treatment, Wherein, the light injection processing step and the scribing processing step are completed in different chambers of the same laser equipment.

[0051] Different chambers of the laser equipment respectively have a first laser light source and a second laser light source, and the first laser light source is used for scribing in the scribing process step. In the light injection step, the second laser light source is used to perform light injection treatment, and the scribing treatment step is after the light injection step. Both the first laser light source and the second laser light source are infrared laser light sources. The number of slices in this scr...

Embodiment 2

[0057] The difference between the second embodiment of the present disclosure and the first embodiment is that in the second embodiment, the dicing processing step is before the light injection processing step. Correspondingly, in the corresponding laser equipment provided in this embodiment, the laser scribing process is first performed on the loaded battery sheet, and then the laser light injection process is performed.

[0058] Compared with the first embodiment, the second embodiment can passivate and strengthen the repair of the defect during the laser light injection treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com