Lithium ion battery negative electrode material as well as preparation method and application method thereof

A technology for lithium-ion batteries and negative electrode materials, which is applied in the manufacture of electrodes, battery electrodes, electrolyte storage batteries, etc., can solve problems such as the absence of further expansion space, and achieve the effects of broad market application value, high electrochemical capacity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

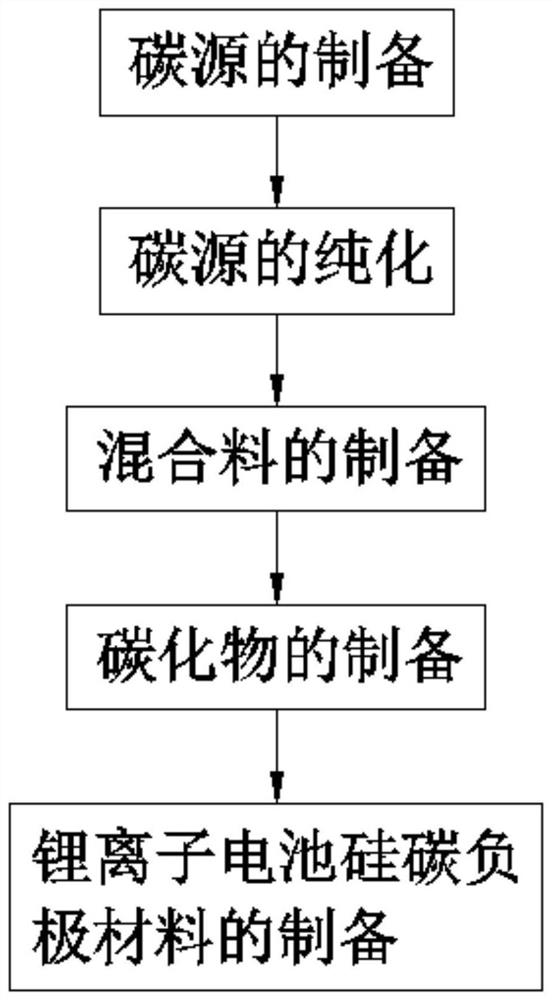

[0031] Embodiment 1: a kind of negative electrode material of lithium ion battery and its preparation method and application method, such as figure 1 Shown, the preparation method of lithium-ion battery negative electrode material comprises the following steps:

[0032] S1. Preparation of carbon source

[0033] Using carbon / carbon composite material leftovers, waste materials, decommissioned waste materials and other residual materials as raw materials, the carbon / carbon composite material residual materials are mechanically crushed through a 100-mesh sieve, burned at 500°C, and then mixed with a strong alkali, at 90 Stir at ℃ until all the water is evaporated, and then carry out graphitization treatment through a graphitization furnace to obtain a carbon source.

[0034] Preferably, the strong base is potassium hydroxide, and the weight ratio of potassium hydroxide to carbon source is 0.5:1.

[0035] Preferably, the graphitization process is as follows: under the protection...

Embodiment 2

[0054] Embodiment 2: A lithium-ion battery negative electrode material and its preparation method and application method. The difference from Example 1 is that the preparation method of the lithium-ion battery negative electrode material comprises the following steps:

[0055] S1. Preparation of carbon source

[0056] Using carbon / carbon composite material leftovers, waste materials, decommissioned waste materials and other residual materials as raw materials, the carbon / carbon composite material residual materials are mechanically crushed through a 50-mesh sieve, burned at 400°C, and then mixed with a strong alkali, and heated at 80 Stir at ℃ until all the water is evaporated, and then carry out graphitization treatment through a graphitization furnace to obtain a carbon source.

[0057] Preferably, the strong base is sodium hydroxide, and the weight ratio of sodium hydroxide to carbon source is 0.1:1.

[0058] Preferably, the graphitization process is as follows: under the ...

Embodiment 3

[0069] Embodiment 3: A lithium ion battery negative electrode material and its preparation method and application method. The difference from Example 1 is that the preparation method of the lithium ion battery negative electrode material comprises the following steps:

[0070] S1. Preparation of carbon source

[0071] Using carbon / carbon composite material leftovers, waste materials, decommissioned waste materials and other residual materials as raw materials, the carbon / carbon composite material residual materials are mechanically crushed through a 150-mesh sieve, burned at 600°C, and then mixed with a strong alkali, at 100 Stir at ℃ until all the water is evaporated, and then carry out graphitization treatment through a graphitization furnace to obtain a carbon source.

[0072] Preferably, the strong base is sodium hydroxide, and the weight ratio of sodium hydroxide to carbon source is 1:1.

[0073] Preferably, the graphitization process is as follows: under the protection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com