Preparation method of low-radioactivity ceramic glaze and prepared ceramic glaze

A ceramic glaze and low-radioactive technology, applied in the field of ceramic glaze, can solve the problems of decreased whiteness and hardness of the glaze surface, affecting the aesthetics and durability of sanitary ceramic products, difficult to remove, etc., to achieve improved hardness and whiteness, uniform Effect of crystallization and low radioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method for low-radioactive ceramic glaze, specifically comprising the steps of:

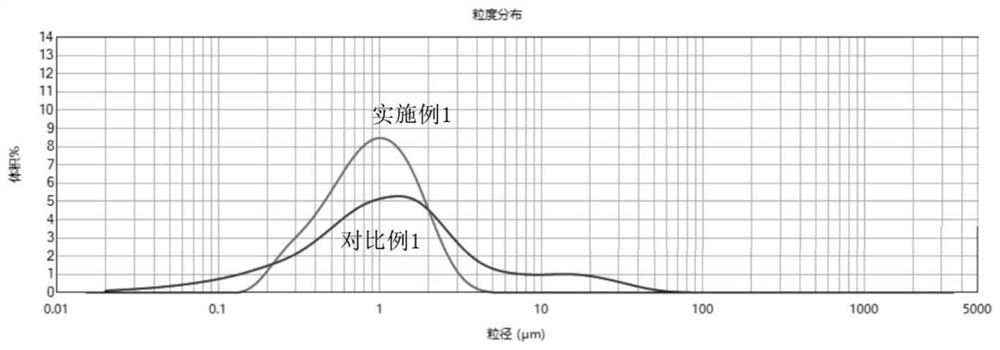

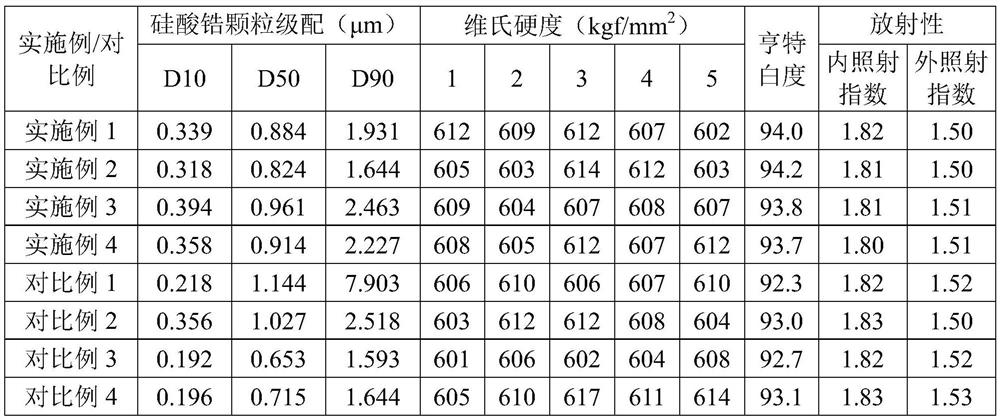

[0044](1) Pre-grinding: In terms of parts by mass, take 10 parts of industrial zirconium silicate, and use 2-3mm alumina microcrystalline balls for ball milling for 30 minutes until the D10, D50, and D90 of zirconium silicate are 0.339 μm, 0.884 μm, and 1.931μm, to get zirconium silicate pre-grinding slurry;

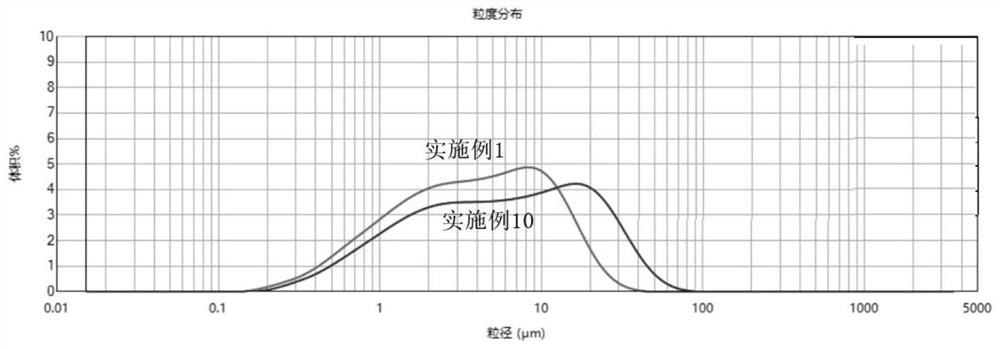

[0045] (2) Primary grinding: without drying, the zirconium silicate pre-grinding slurry is directly mixed with 16 parts of potassium feldspar, 6 parts of albite, 30 parts of quartz, 3 parts of alumina, 13 parts of calcite, dolomite 6 parts, 7 parts of wollastonite and 3 parts of frit are mixed, after adding water, ball mill with high alumina ball until the slurry D10≤1.5μm, D50≤5μm, D90≤15μm, to obtain primary grinding slurry;

[0046] (3) Final grinding: add 2 parts of zinc oxide and 5 parts of kaolin to the primary grinding slurry, continue ball milling until D10, D5...

Embodiment 2

[0049] Compared with Example 1, the only difference in this example is that the zirconium silicate pre-grinding slurry D10, D50, and D90 are respectively 0.318 μm, 0.824 μm, and 1.644 μm, and the others are the same as in Example 1.

Embodiment 3

[0051] Compared with Example 1, the only difference in this example is that the zirconium silicate pre-grinding slurry D10, D50, and D90 are 0.394 μm, 0.961 μm, and 2.463 μm, respectively, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com