Boron- modified urushiol phenolic resin, preparation method and coating containing boron- modified urushiol phenolic resin

A technology of phenolic resin and urushiol resin is applied in the field of preparation method and coating containing the same, and boron-modified urushiol phenolic resin to achieve the effects of uniform reaction and excellent acid and alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example provides a method for extracting urushiol from raw lacquer. The specific operation steps are as follows: mix raw lacquer with 1:1 xylene and stir thoroughly, filter and then distill to remove water and xylene to obtain 30%wt-40%wt Urushiol xylene solution.

Embodiment 2

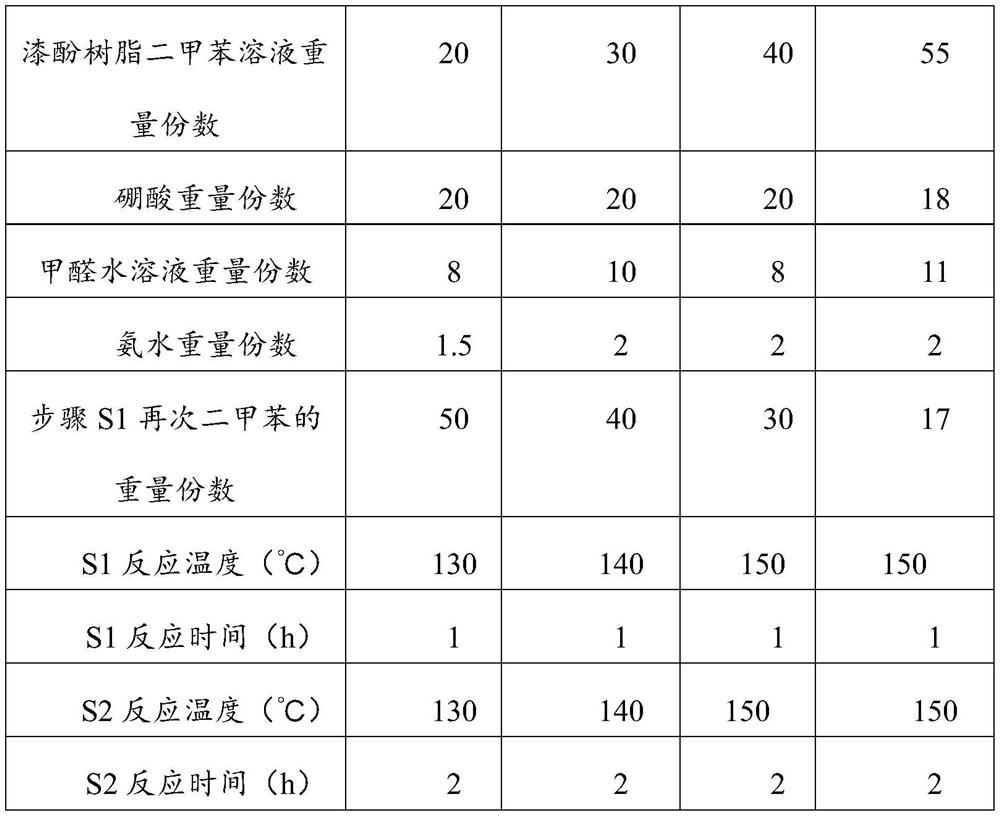

[0044] This embodiment provides the boron-modified urushiol phenolic resin prepared by different boron-modified urushiol phenolic resin preparation methods, and the specific operation steps are as follows:

[0045] Step S1: adding the urushiol resin xylene solution of Example 1 and boric acid, adding xylene again, and reacting to obtain urushiol borate;

[0046] Step S2: Condensation reaction of urushiol borate and 37%wt-40%wt formaldehyde solution under the catalysis of ammonia water to obtain boron-modified urushiol phenolic resin.

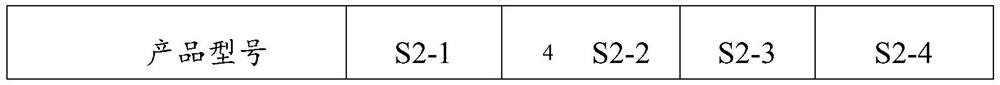

[0047] The specific raw material ratios and reaction conditions of different types of boron-modified urushiol phenolic resins are shown in Table 1.

[0048] Table 1 different types of boron modified urushiol phenolic resin preparation method

[0049]

[0050]

[0051] In the above table, the parts by weight of urushiol resin, formaldehyde and the parts by weight of solvent are calculated as follows:

[0052] Product number S2-1...

Embodiment 3

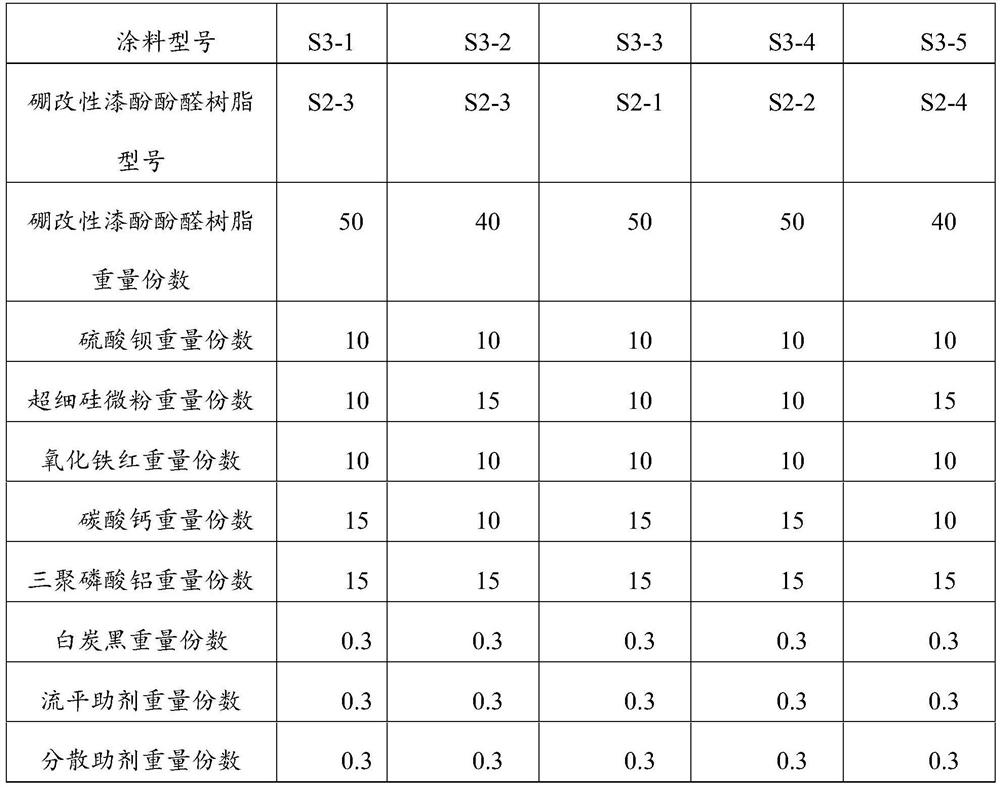

[0060] The present embodiment provides the different types of coatings prepared by the boron-modified urushiol phenolic resin of the embodiment 2 model, and its specific preparation method is as follows;

[0061] The formula in Table 3 was mixed in proportion under the condition of 40°C to 50°C, fully stirred evenly, ground for 15-20 minutes, and filtered to obtain the coating.

[0062] In this embodiment, the specific substances or sources related to raw materials are as follows:

[0063] Barium sulfate: Henan Bafeng Chemical Co., Ltd., superfine precipitated barium sulfate, first-class product

[0064] Ultrafine silica powder: Shenzhen Haiyang Powder Technology Co., Ltd. YH-G10

[0065] Iron oxide red: Zibo Baoyan Chemical Co., Ltd. A-130#

[0066]Calcium carbonate: Kelong Powder Co., Ltd. CC988

[0067] Aluminum tripolyphosphate; Jinan Huijinchuan Chemical Co., Ltd.

[0068] Silica: Shanghai Kaiyin Chemical Co., Ltd. N20

[0069] Leveling aid: BYK 466

[0070] Dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com