Preparation device of biodegradable polyester material fused with soil base material

A technology of biodegradable polyester and preparation device, applied in the field of preparation device of biodegradable polyester material, can solve the problem of difficult degradation of plastic films, and achieve the effect of improving quality and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A biodegradable polyester material blended with the base soil matrix, the material is made of the following components by weight: 100 parts of biodegradable polyester, 30 parts of plasticizer, 25 parts of inorganic filler, 0.2 parts of antioxidant 60 parts of starch, 20 parts of lignin, 2 parts of lubricant;

[0045] The biodegradable polyester is one or a mixture of polylactic acid and poly(butylene terephthalate-CO-butylene adipate) ester; the plasticizer is diacetyl epoxy vegetable glycerin, inorganic filler At least one of calcium carbonate, kaolin, talc, titanium dioxide, mica, and montmorillonite; lignin is organic solvent lignin, sulfate lignin, alkali extraction lignin, enzymatic lignin or paper lignin Any one of them; the plasticizer is any one or a combination of ethylene glycol, glycerin, and sorbitol.

[0046] The present invention prevents starch from regenerating through the hydrogen bond and esterification reaction between lignin and starch, and the mast...

Embodiment 2

[0052] A biodegradable polyester material blended with the base soil matrix, the material is made of the following components by weight: 120 parts of biodegradable polyester, 5 parts of plasticizer, 200 parts of inorganic filler, 1 part of antioxidant 40 parts of starch, 30 parts of lignin, 0.8 parts of lubricant;

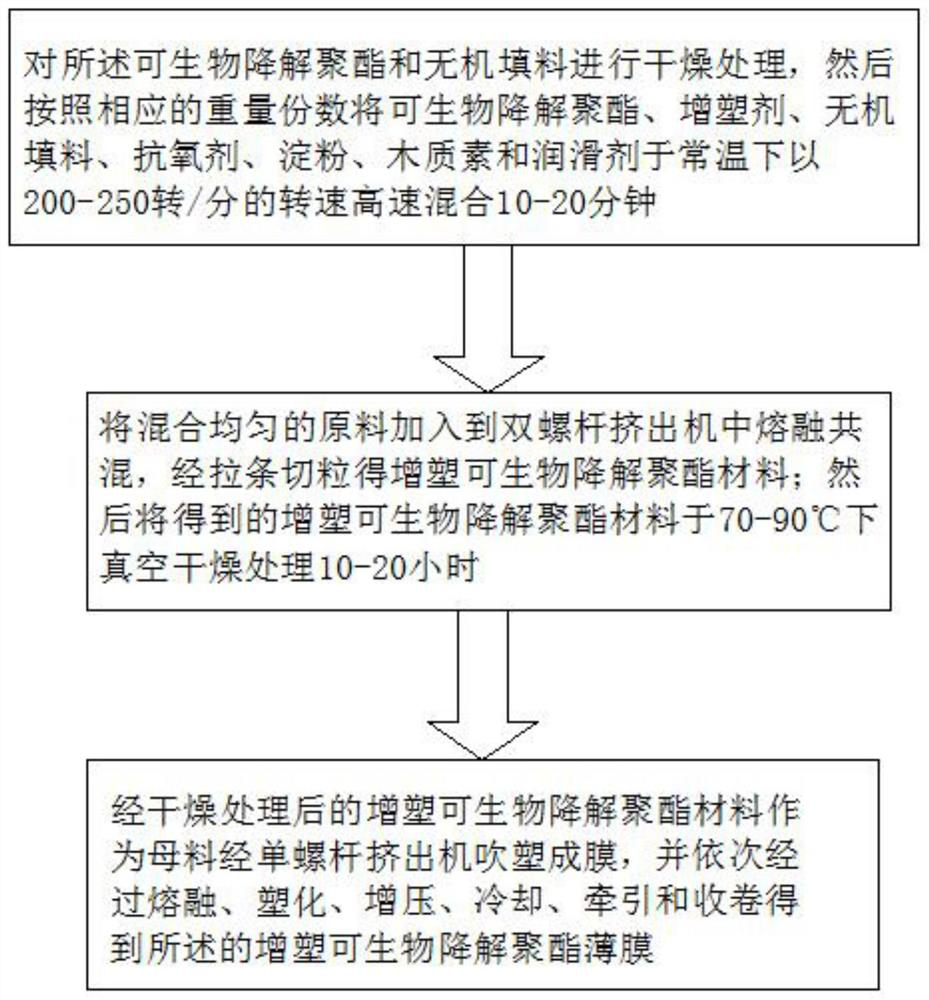

[0053] refer to figure 1 , a preparation process of a biodegradable polyester material blended with a base soil matrix, comprising the following steps;

[0054] Step 1: Dry the biodegradable polyester and inorganic filler, and then mix the biodegradable polyester, plasticizer, inorganic filler, antioxidant, starch, lignin and lubricant according to the corresponding parts by weight Mix at a high speed of 250 rpm for 10 minutes at room temperature;

[0055] Step 2: Add the homogeneously mixed raw materials into a twin-screw extruder for melt blending, and pelletize the plasticized biodegradable polyester material through the strands; then put the obtained plastici...

Embodiment 3

[0059] Embodiment 3 is an improvement to Embodiment 2. After extruding the plastic film in semi-molten state by the extruder, a tubular plastic film is formed. At this time, the tubular shape needs to be positioned and clamped. There is no such thing as the positioning and clamping of the prior art. Rapid cooling of the plastic film in the semi-molten state, so that the plastic film in the semi-molten state easily adheres to the clamping plate, and the integrity of the plastic film is destroyed; in addition, during the film cutting and winding process, the cutter When the tubular plastic film is cut into a film, it is rewound by the rewinding wheel. However, the independent driving device of the rewinding wheel and the film cutting process in the prior art cannot be synchronized, and it is easy to cause the rewinding wheel to rotate too fast or Too slow leads to problems with film breakage and buildup.

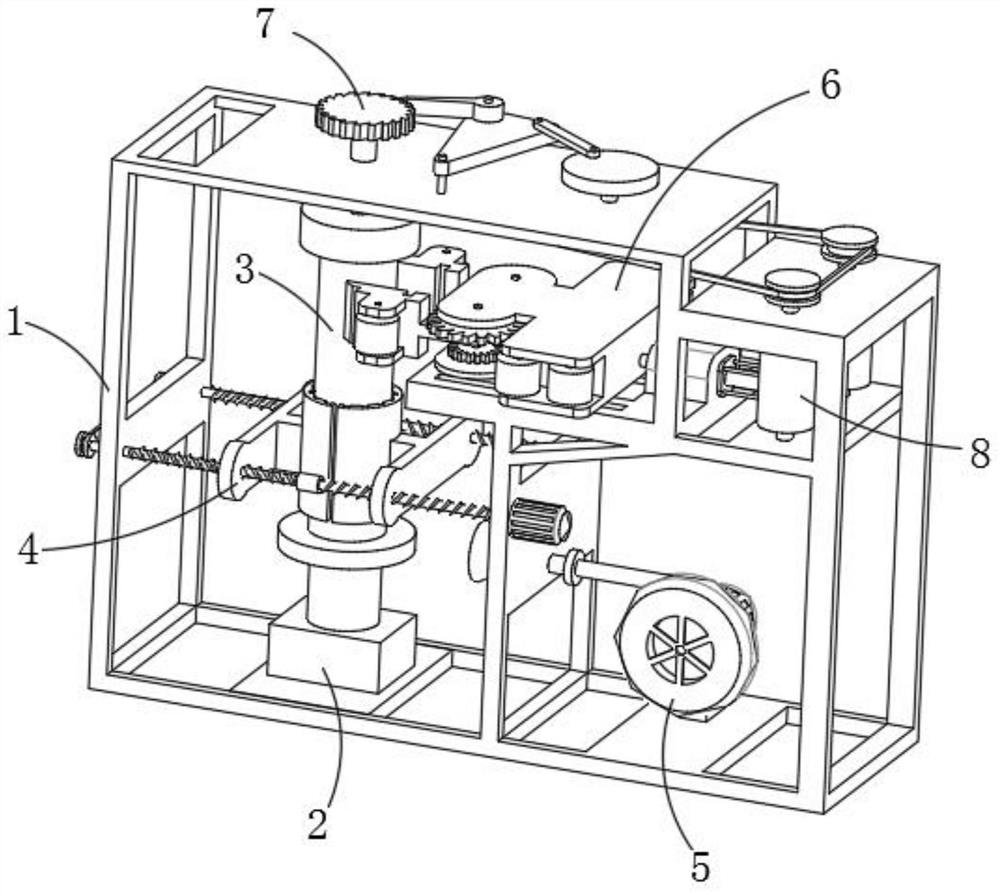

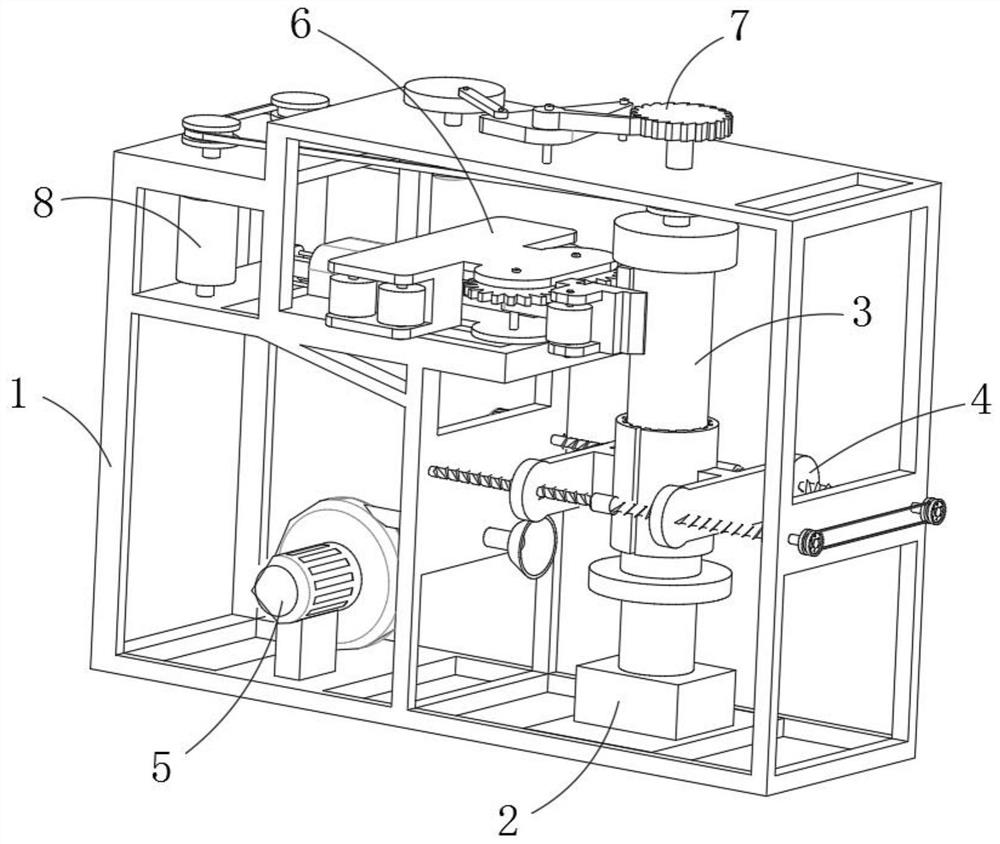

[0060] refer to Figure 2-11 A preparation device for a biodegradable po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com