Ceramic heating body, method, infrared heating tube and equipment

A technology of ceramic heating elements and equipment, which is applied in the fields of ceramic heating elements, infrared heating tubes, and ceramic heating elements. The effect of high production process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

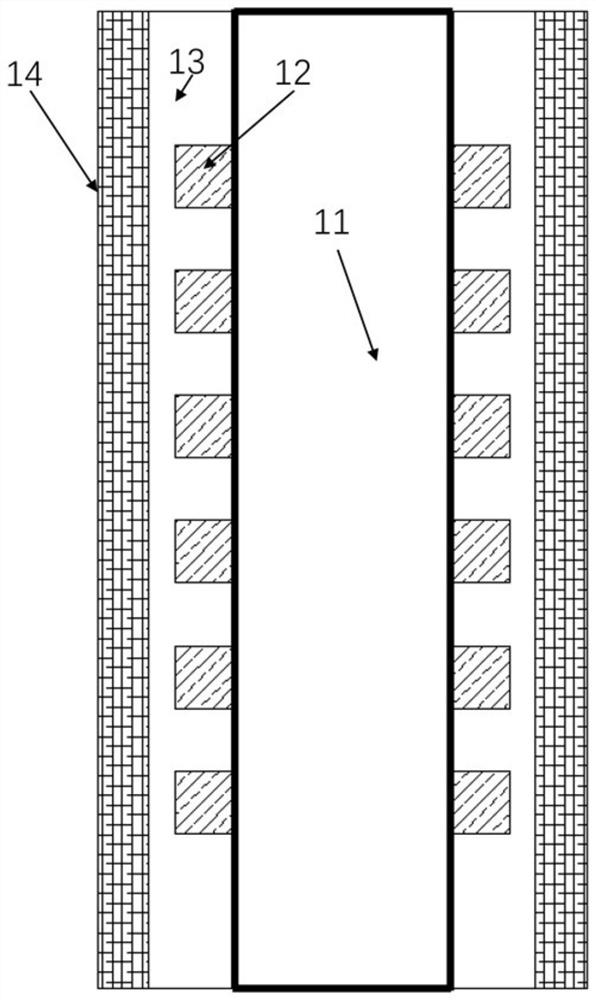

Embodiment 1

[0050] Such as figure 1 As shown, the ceramic heating element described in Embodiment 1 of the present invention; the ceramic substrate 11 is a single-layer ceramic material, and its material is preferably aluminum oxide, and can also be silicon dioxide, aluminum nitride, silicon carbide, zirconia, cordierite , Mullite and other simple substances or their composite materials;

[0051] The resistive conductive layer 12, the conductive layer 12 can be made of iron, copper, zinc, nickel, tungsten, molybdenum, tin, gold, silver, manganese, titanium, lanthanide metals and their oxides, nitrides, carbides, etc. one or more. The conductive layer 12 is generally controlled to be between 50 nanometers and 5000 nanometers, depending on specific requirements. ;

[0052] The cladding layer 13 is made of the same material or the same system as the ceramic substrate 11, and its material is preferably aluminum oxide, and can also be simple substances such as silicon dioxide, aluminum nitr...

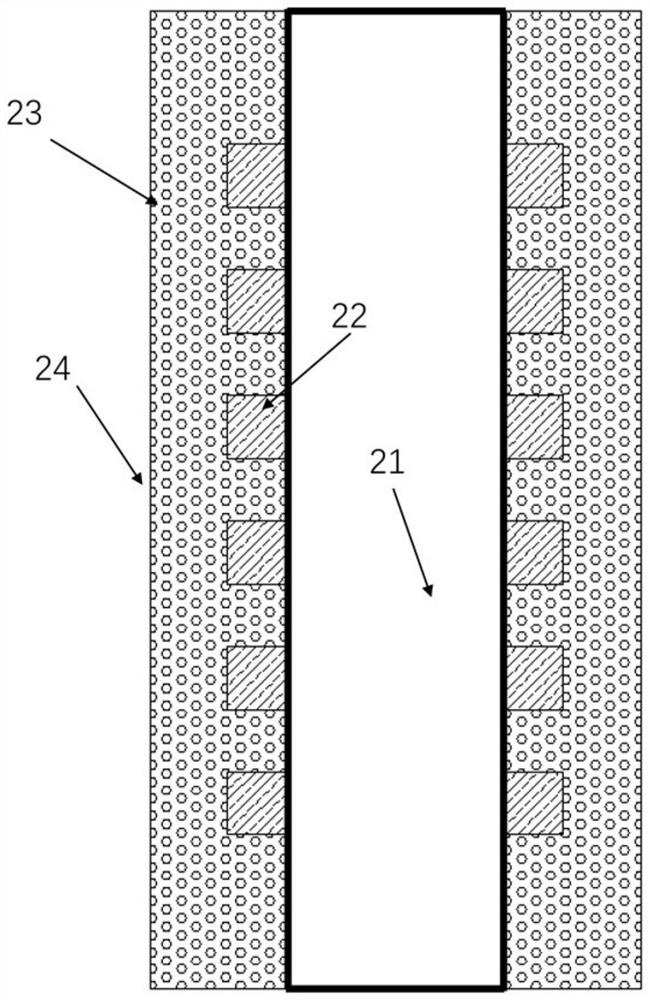

Embodiment 2

[0055] Such as figure 2 As shown, the ceramic heating element described in Embodiment 2 of the present invention; the ceramic substrate 21 is a single-layer ceramic material, and its material is preferably aluminum oxide, and can also be silicon dioxide, aluminum nitride, silicon carbide, zirconia, cordierite , Mullite and other simple substances or their composite materials;

[0056] The resistive conductive layer 22, the conductive layer 22 can be made of iron, copper, zinc, nickel, tungsten, molybdenum, tin, gold, silver, manganese, titanium, lanthanide metals and their oxides, nitrides, carbides, etc. One or more; the conductive layer 22 is generally controlled between 50 nanometers and 5000 nanometers, depending on specific requirements.

[0057] The cladding layer 23 of the conductive resistor is the same as the single-layer ceramic material of the substrate 21 or a material of the same system, and its material is preferably aluminum oxide, and can also be silicon diox...

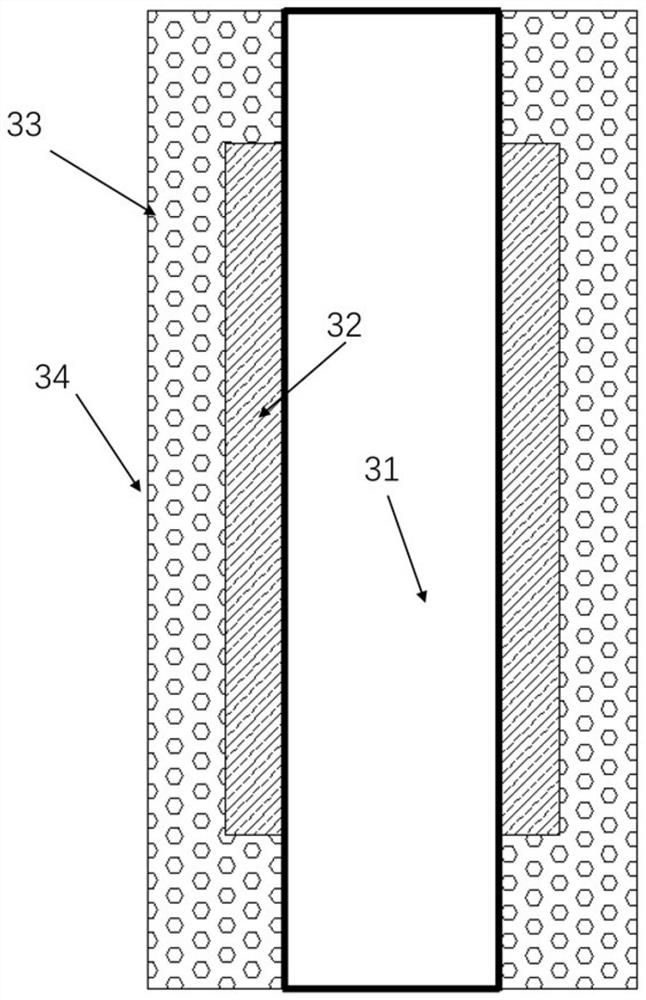

Embodiment 3

[0067] Such as image 3 As shown, the ceramic heating element described in Embodiment 3 of the present invention; the ceramic substrate 31 is a single-layer ceramic material, and its material is preferably aluminum oxide, and can also be silicon dioxide, aluminum nitride, silicon carbide, zirconia, cordierite , Mullite and other simple substances or their composite materials;

[0068] The resistive conductive layer 32, the conductive layer 32 can be made of iron, copper, zinc, nickel, tungsten, molybdenum, tin, gold, silver, manganese, titanium, lanthanide metals and their oxides, nitrides, carbides, etc. One or more; the conductive layer 32 is generally controlled between 50 nanometers and 5000 nanometers, depending on specific requirements.

[0069] The coating layer 33 of the conductive resistor is the same as the single-layer ceramic material of the substrate 31 or a material of the same system, and its material is preferably aluminum oxide, and can also be silicon dioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com