Straight waveguide phase modulator, integrated assembly and preparation method

A phase modulator and straight waveguide technology, applied in instruments, voltage/current isolation, measurement devices, etc., can solve the reliability of fiber optic current transformers, the impact of assembly complexity, the impact of manufacturing costs, different coupling efficiencies, and the impact of contrast. Achieve the effect of reducing the complexity of optical path assembly, improving system reliability, and reducing fiber splicing points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

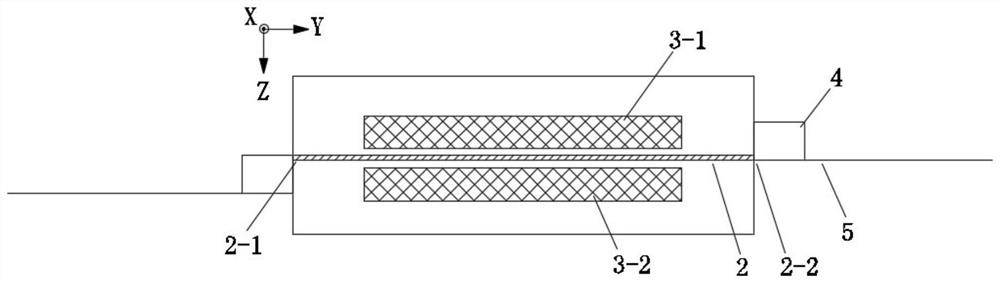

[0069] refer to figure 2 , shown in the figure is a schematic structural diagram of the straight waveguide phase modulator provided by this embodiment. A straight waveguide phase modulator, comprising: a lithium tantalate base wafer 1, which has an electro-optical effect; a straight waveguide 2, which is a zinc oxide diffused optical waveguide, formed in the lithium tantalate base wafer 1; a metal electrode 3, used for The light wave transmitted in the straight waveguide 2 is modulated; the optical fiber crystal carrier block 4 is made with a groove on the surface or a round hole in the center for placing the polarization maintaining optical fiber 5, which is formed on the lithium tantalate substrate wafer 1 after polishing Straight waveguides in 2-coupling bonding.

[0070] As the base wafer and the substrate medium used to form the optical waveguide, the lithium tantalate base wafer 1 is an optical-grade crystal material. Lithium tantalate crystal materials with the same ...

Embodiment 2

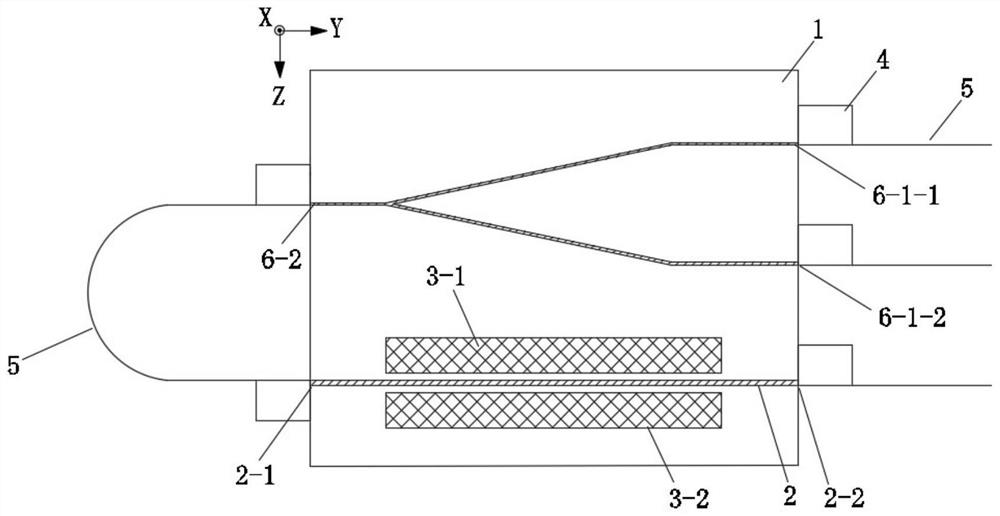

[0079] refer to image 3 , which is a schematic structural diagram of an embodiment of the integrated component provided by this embodiment. An integrated component includes: a lithium tantalate base wafer 1 , a straight waveguide 2 , a metal electrode 3 , an optical fiber crystal carrier block 4 , a polarization-maintaining optical fiber 5 , and a Y-branch waveguide coupler 6 . Among them, the structures of the lithium tantalate base wafer 1 , the straight waveguide 2 , the metal electrode 3 , and the optical fiber crystal carrier block 4 are the same as in the embodiment 1, and will not be described in detail here.

[0080] The Y-branch waveguide coupler 6 integrates two important functions of the waveguide coupler and the waveguide polarizer, among which: the function of the waveguide coupler is realized through the Y-branch structure; Feature implementation.

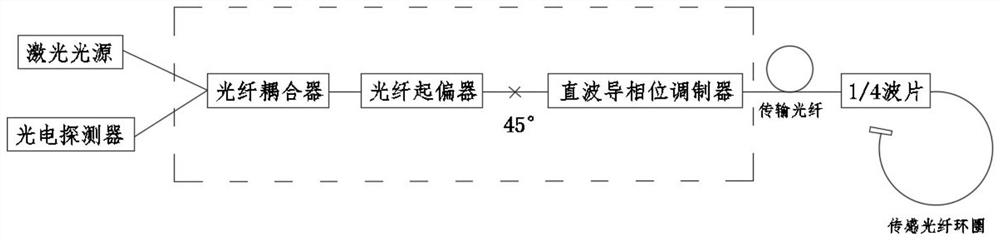

[0081] refer to image 3 , this embodiment can be figure 1 Each discrete optical fiber device in the dotted bl...

Embodiment 3

[0084] refer to Figure 5 , which is a schematic structural diagram of the integrated components provided by this embodiment. In order to further improve the integration of integrated components, improve the reliability of components, reduce assembly difficulty and manufacturing cost, on the basis of Embodiment 2, this embodiment improves the fiber crystal carrier block 4 by adopting multi-channel fiber crystal carrier block 4 and place a polarization-maintaining optical fiber 5 in each channel to form a multi-channel optical fiber array.

[0085] Specifically, it includes: a lithium tantalate base wafer 1 , a straight waveguide 2 , a metal electrode 3 , an optical fiber crystal carrier block 4 , a polarization-maintaining optical fiber 5 , and a Y-branch waveguide coupler 6 . Among them, the structures of the lithium tantalate base wafer 1 , the straight waveguide 2 , the metal electrode 3 , and the Y-branch waveguide coupler 6 are the same as those in Embodiment 2, and will...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com