An implantable zinc-based alloy surface structure and its preparation method and application

A surface structure and zinc alloy technology, which is applied in metal material coating process, liquid chemical plating, surgery, etc., can solve the problems of unguaranteed phosphate film composition, poor biocompatibility and complex composition of zinc hydroxide, etc. Achieve the effects of adjustable degradation rate, accelerated bone healing, and increased proliferation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

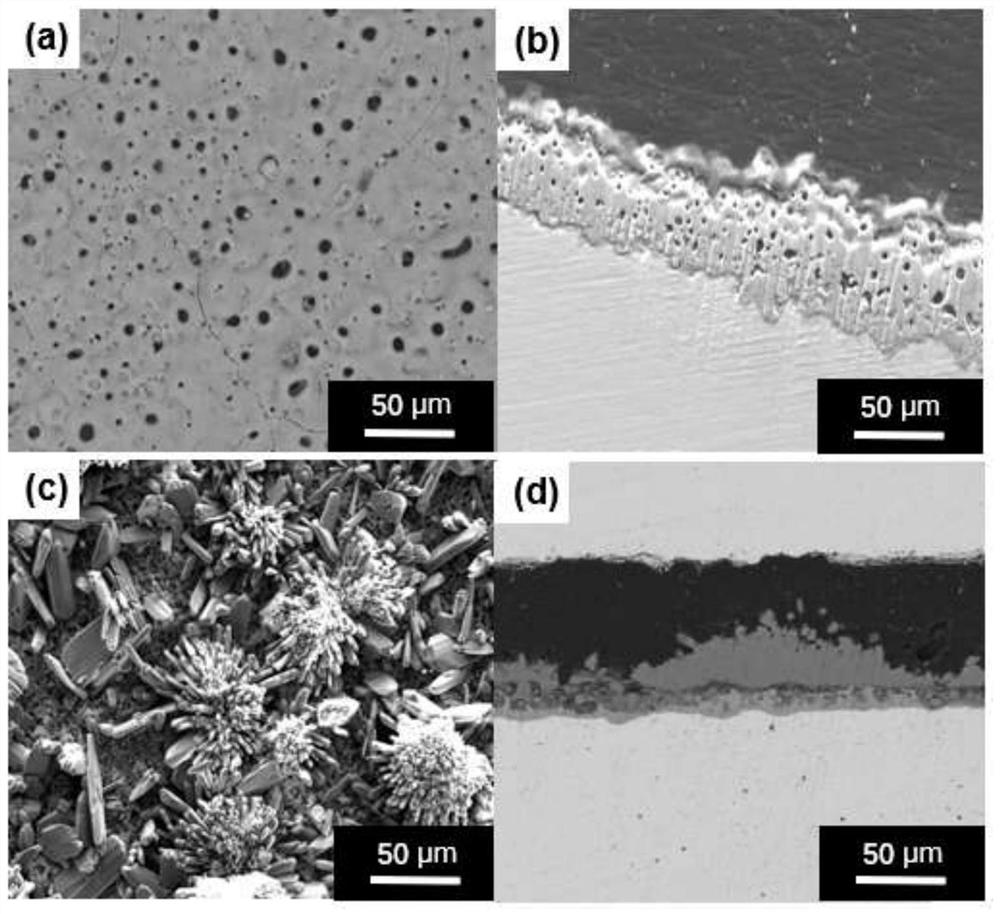

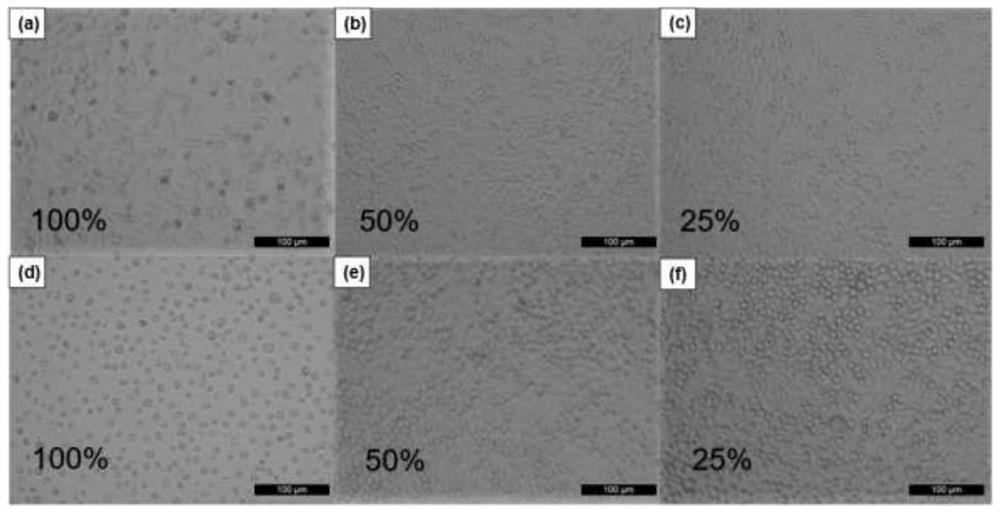

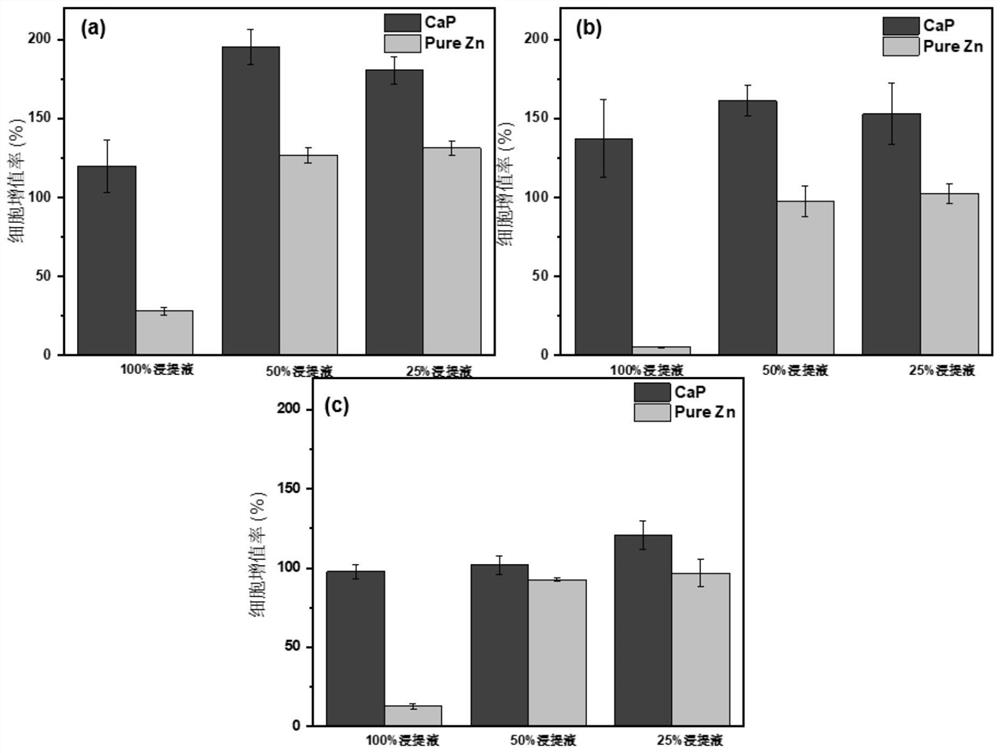

[0039] In this example, pure zinc is used as the substrate, and the wires are connected by micro-arc oxidation. The micro-arc oxidation voltage is 450V, and the micro-arc oxidation is performed for 15 minutes to obtain a surface porous structure; In the reaction kettle of the sodium calcium and phosphorus precursor liquid (20mL), the content of the calcium nitrate and sodium dihydrogen phosphate were 3.94g and 1.19g respectively, dissolved in 100mL of water, and the calcium to phosphorus mass ratio was 1.67. The reaction temperature was 110 °C and the reaction time was 16 hours to obtain an implantable zinc-based alloy surface structure, such as figure 1 As shown, the surface cross-sectional structure and morphology of the zinc-based alloy prepared in Example 1, (a) is a porous oxide layer, with uniform pores, small surface roughness, and slight cracks; it can be seen from the cross-section (b) that the porous The oxide layer is well bonded to the substrate; (c) (d) are the po...

Embodiment 2

[0045] In this example, a zinc-lithium alloy is used as the matrix, Zn: 99.5 wt.%, Li: 0.5 wt.%, micro-arc oxidation after connecting wires, the micro-arc oxidation voltage is 450V, and the micro-arc oxidation is 15 minutes to obtain a surface porous structure; The obtained surface porous structure is put into the reactor containing the calcium and phosphorus precursor liquid (20mL) of calcium nitrate and sodium dihydrogen phosphate, and the content of described calcium nitrate and sodium dihydrogen phosphate is respectively 4.28g, 1.19g , dissolved in 100mL of water, the mass ratio of calcium to phosphorus: 1.8. The reaction temperature was 110 °C and the reaction time was 16 hours to obtain an implantable zinc-based alloy surface structure, such as Figure 4 As shown, the surface porous structure is as Figure 4 As shown in (a), the pores are uniform, the surface roughness is small, and there are slight cracks; the calcium phosphate layer is as Figure 4 As shown in (b), t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com