Porous MOFs type metal oxide and application thereof in atmosphere purification

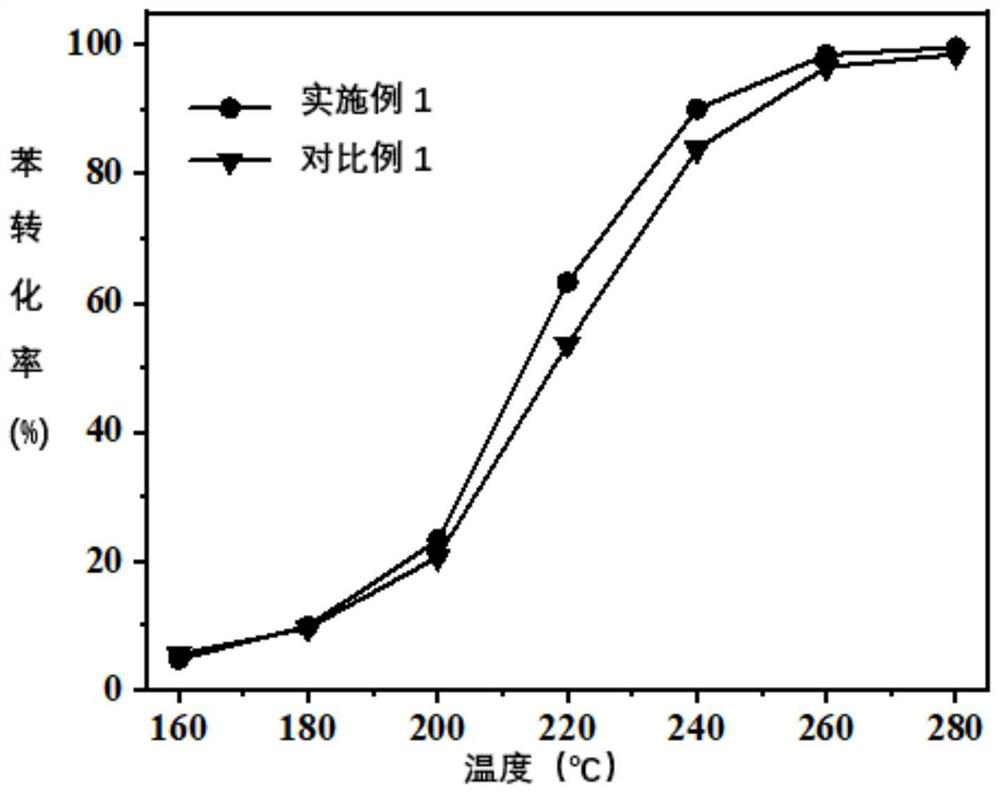

An oxide and metal technology, applied in the field of atmospheric environment purification, can solve the problems of single photocatalytic active component and low catalytic performance, and achieve the effect of enhanced catalytic elimination effect, uniform particle size and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

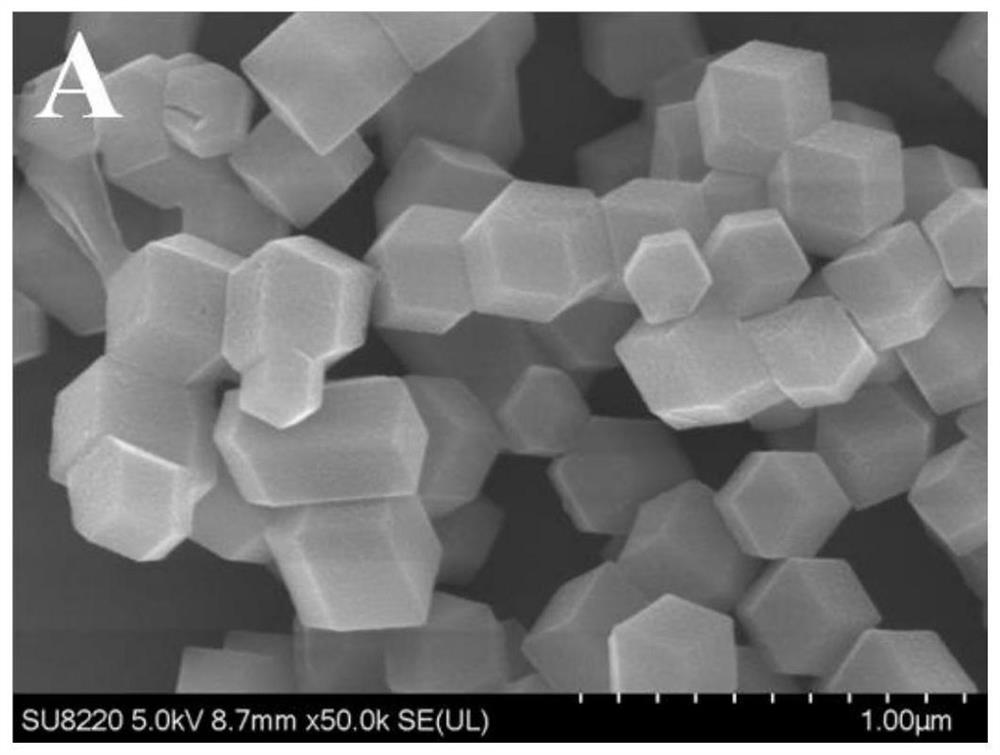

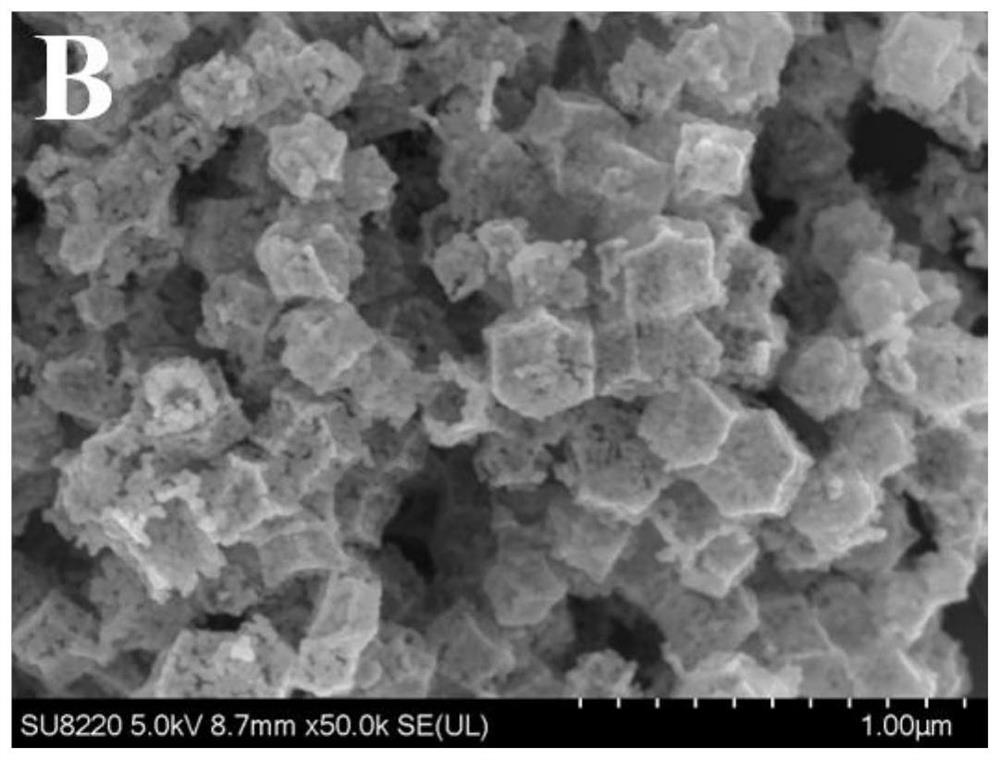

[0053] A porous MOFs-type metal oxide is prepared by using the porous MOFs as the outer shell and the metal oxide as the inner core.

[0054] The preparation method of described porous MOFs is:

[0055] S1. Weigh the rhenium salt and add it to the first organic solvent, and stir until it is completely dissolved to obtain a rhenium salt solution;

[0056] Wherein, the mass concentration of rhenium salt solution is 0.06g / mL;

[0057] S2. Weigh 1-(4-hydrazinophenyl)methyl-1,2,4-triazole and add it to the first organic solvent, and stir until it is completely dissolved to obtain 1-(4-hydrazinophenyl ) methyl-1,2,4-triazole solution;

[0058] Wherein, the mass concentration of 1-(4-hydrazinophenyl)methyl-1,2,4-triazole solution is 0.1g / mL;

[0059] S3. Add coumaric acid to the 1-(4-hydrazinophenyl)methyl-1,2,4-triazole solution, and stir until completely dissolved to obtain an organic mixed solution;

[0060] Wherein, in the organic mixed solution, the mass concentration of cou...

Embodiment 2

[0086] A porous MOFs-type metal oxide is prepared by using the porous MOFs as the outer shell and the metal oxide as the inner core.

[0087] The preparation method of described porous MOFs is:

[0088] S1. Weigh the rhenium salt and add it to the first organic solvent, and stir until it is completely dissolved to obtain a rhenium salt solution;

[0089] Wherein, the mass concentration of rhenium salt solution is 0.01g / mL;

[0090] S2. Weigh 1-(4-hydrazinophenyl)methyl-1,2,4-triazole and add it to the first organic solvent, and stir until it is completely dissolved to obtain 1-(4-hydrazinophenyl ) methyl-1,2,4-triazole solution;

[0091] Wherein, the mass concentration of 1-(4-hydrazinophenyl)methyl-1,2,4-triazole solution is 0.02g / mL;

[0092] S3. Add coumaric acid to the 1-(4-hydrazinophenyl)methyl-1,2,4-triazole solution, and stir until completely dissolved to obtain an organic mixed solution;

[0093] Wherein, in the organic mixed solution, the mass concentration of co...

Embodiment 3

[0119] A porous MOFs-type metal oxide is prepared by using the porous MOFs as the outer shell and the metal oxide as the inner core.

[0120] The preparation method of described porous MOFs is:

[0121] S1. Weigh the rhenium salt and add it to the first organic solvent, and stir until it is completely dissolved to obtain a rhenium salt solution;

[0122] Wherein, the mass concentration of rhenium salt solution is 0.03g / mL;

[0123] S2. Weigh 1-(4-hydrazinophenyl)methyl-1,2,4-triazole and add it to the first organic solvent, and stir until it is completely dissolved to obtain 1-(4-hydrazinophenyl ) methyl-1,2,4-triazole solution;

[0124] Wherein, the mass concentration of 1-(4-hydrazinophenyl)methyl-1,2,4-triazole solution is 0.06g / mL;

[0125] S3. Add coumaric acid to the 1-(4-hydrazinophenyl)methyl-1,2,4-triazole solution, and stir until completely dissolved to obtain an organic mixed solution;

[0126] Wherein, in the organic mixed solution, the mass concentration of co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com