Chlorine-resistant composite reverse osmosis membrane and preparation method thereof

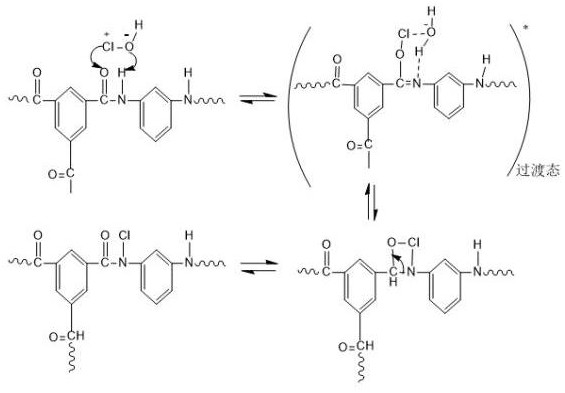

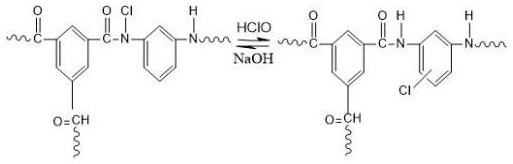

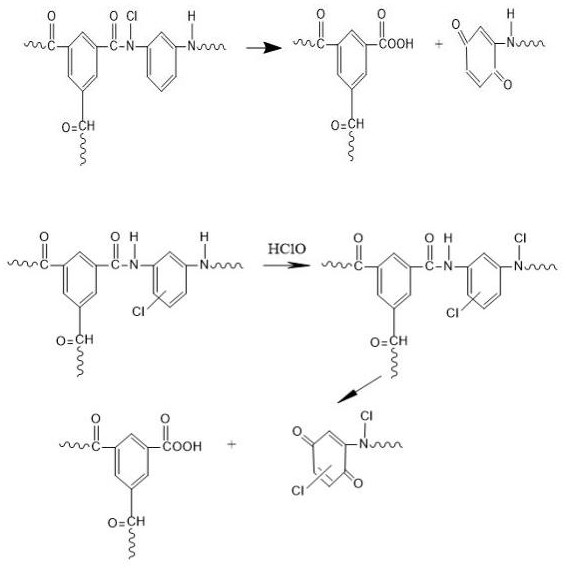

A reverse osmosis membrane and chlorine-resistant technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as reverse osmosis membrane damage, achieve enhanced chlorine resistance, reduce orton rearrangement, and enhance densification sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First, the plasma generated in the argon plasma generator was sprayed on the surface of the polysulfone ultrafiltration base membrane by a low-temperature plasma spray gun for 50 seconds, and then the polysulfone ultrafiltration base membrane was soaked in an aqueous solution of chlorosulfonic acid with a mass concentration of 1% for 5 minutes, and then the polysulfone ultrafiltration base membrane was soaked for 5 minutes. Soak the sulfone ultrafiltration base membrane in 0.1% 2,5-diaminotrifluorotoluene aqueous solution for 1 min, and dry to obtain the polysulfone ultrafiltration base membrane 1; immerse the polysulfone ultrafiltration base membrane 1 with a mass concentration of 0.05 % of trimesoyl chloride in n-heptane organic solution for 10s, to obtain the polysulfone ultrafiltration base membrane II; heat-treat the polysulfone ultrafiltration base membrane II in an oven at 100°C for 10 minutes to obtain a composite reverse osmosis membrane, Store it in deionized w...

Embodiment 2

[0034] First, the plasma generated in the argon plasma generator was sprayed on the surface of the polysulfone ultrafiltration base membrane by a low-temperature plasma spray gun for 60 seconds, and then the polysulfone ultrafiltration base membrane was soaked in an aqueous solution of chlorosulfonic acid with a mass concentration of 2% for 5 minutes, and then the polysulfone ultrafiltration base membrane was soaked for 5 minutes. Soak the sulfone ultrafiltration base membrane in 1% 2,5-diaminotrifluorotoluene aqueous solution for 1 min, and dry to obtain the polysulfone ultrafiltration base membrane 1; immerse the polysulfone ultrafiltration base membrane 1 with a mass concentration of 0.1 % of trimesoyl chloride in n-heptane organic solution for 30s, the polysulfone ultrafiltration base membrane II was obtained; the polysulfone ultrafiltration base membrane II was heat-treated in an oven at 110°C for 10 minutes to obtain a composite reverse osmosis membrane, Store it in deion...

Embodiment 3

[0036] First, the plasma generated in the argon plasma generator was sprayed on the surface of the polysulfone ultrafiltration base membrane by a low-temperature plasma spray gun for 60 seconds, and then the polysulfone ultrafiltration base membrane was soaked in an aqueous solution of chlorosulfonic acid with a mass concentration of 3% for 8 minutes, and then the polysulfone ultrafiltration base membrane was soaked for 8 minutes. The sulfone ultrafiltration base membrane was soaked in 2,5-diaminotrifluorotoluene aqueous solution with a mass concentration of 2.5% for 3 minutes, and dried to obtain a polysulfone ultrafiltration base membrane one; the polysulfone ultrafiltration base membrane one was immersed in a mass concentration of 0.15 % of trimesoyl chloride in n-heptane organic solution for 50s to obtain polysulfone ultrafiltration base membrane II; polysulfone ultrafiltration base membrane II was heat-treated in an oven at 110°C for 15 minutes to obtain a composite reverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com