In-device regeneration method of inactivated titanium silicalite molecular sieve

A titanium-silicon molecular sieve and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, catalyst regeneration/reactivation, etc., can solve the problem of difficult catalyst regeneration, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

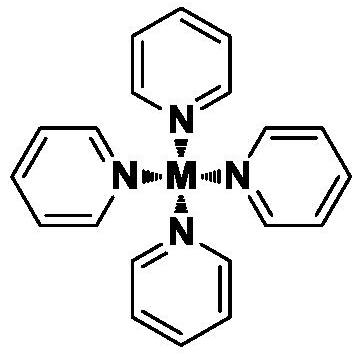

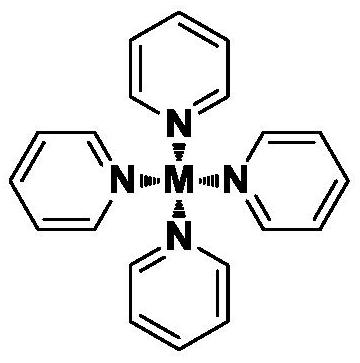

[0035] Take a three-neck flask and add 200g of 50% ferrous sulfate solution and 20g of pyridine successively, stir at normal temperature and pressure for 3h, evaporate the solvent to dryness, wash and dry to obtain the metal ligand catalyst II. Elemental analysis results: C64.53%, H5.42%, Fe15.00%, N15.05%. The NMR results are as follows: 1 H NMR (600MHz, CDCl3): δ7.36(8H), 8.59(8H), 8.98(4H).

[0036] The loading amount of catalyst TS-1 in the reactor is 100g. At normal temperature and pressure, 20kg of toluene was injected into the reactor at a rate of 1kg / h to wash the deactivated catalyst.

[0037] After mixing 10 g of catalyst II and 10 kg of tert-butyl hydroperoxide solution (concentration 10%), inject it into the reactor at a speed of 500 g / h at 150° C. to decompose the tar on the deactivated catalyst.

[0038] At normal temperature and pressure, 5 kg of toluene was injected into the reactor at a rate of 100 g / h to clean the small molecule products produced by the de...

Embodiment 2

[0041] Take a three-neck flask and add 6000g of 5% manganese sulfate solution and 60g of pyridine in sequence, stir for 3 hours at normal temperature and pressure, evaporate the solvent to dryness, wash and dry to obtain the metal ligand catalyst II. Elemental analysis results: C 64.69%, H 5.43%, Mn 14.79%, N 15.09%. The NMR results are as follows: 1 H NMR (600MHz, CDCl3): δ7.36(8H), 8.59(8H), 8.98(4H).

[0042] The loading amount of catalyst TS-1 in the reactor is 100g. At normal temperature and pressure, 5 kg of DMF was injected into the reactor at a rate of 100 g / h to wash the deactivated catalyst.

[0043] After mixing 50 g of catalyst II and 5 kg of peracetic acid solution (concentration 15%), inject it into the reactor at a speed of 50 g / h at 60° C. to decompose the tar on the deactivated catalyst.

[0044]At normal temperature and pressure, 20kg of tetrahydrofuran was injected into the reactor at a rate of 1000g / h to clean the small molecule products produced by the ...

Embodiment 3

[0047] Take a three-neck flask and add 800g of 20% cobalt nitrate solution and 20g of pyridine in sequence, stir at normal temperature and pressure for 3 hours, evaporate the solvent to dryness, wash and dry to obtain the metal ligand catalyst II. Elemental analysis results: C 64.00%, H 5.37%, Co 15.70%, N 14.93%. The NMR results are as follows: 1 H NMR (600MHz, CDCl3): δ7.36(8H), 8.59(8H), 8.98(4H).

[0048] The loading amount of catalyst TS-1 in the reactor is 100g. At normal temperature and pressure, 10kg of acetone was injected into the reactor at a rate of 400g / h to wash the deactivated catalyst.

[0049] After mixing 10 g of Catalyst II and 2 kg of hydrogen peroxide solution (concentration 27%), inject it into the reactor at a rate of 300 g / h at 70° C. to decompose the tar on the deactivated catalyst.

[0050] At normal temperature and pressure, 10kg of cumene was injected into the reactor at a rate of 300g / h to clean the small molecule products produced by the decomp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com