Ultrasonic wave-hydrogen peroxide enhanced zinc oxide smoke dust leaching method

A zinc oxide and ultrasonic technology, applied in the field of hydrometallurgy, can solve the problems of environmental pollution, waste of resources, etc., and achieve the effects of high comprehensive recovery rate, consumption saving and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

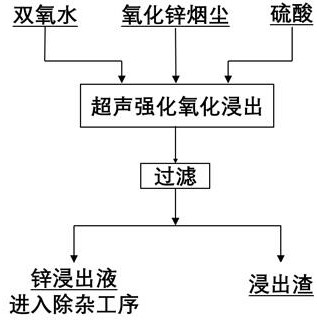

Method used

Image

Examples

Embodiment 1

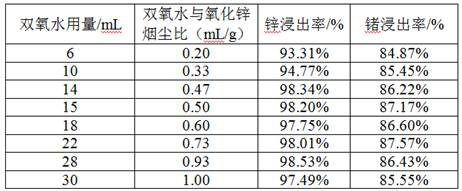

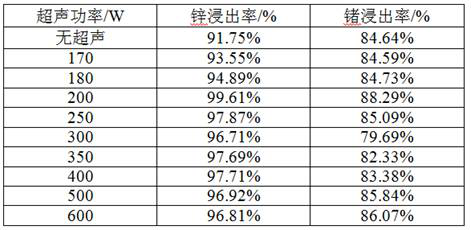

[0035] Mix 30% hydrogen peroxide and 98% sulfuric acid at a mass ratio of 0.30:1 to obtain a mixed leaching agent with a sulfuric acid concentration of 160g / L. Zinc oxide dust is mixed with the mixed leaching agent at a liquid-solid mass ratio of 5:1. (Based on 30% concentration of hydrogen peroxide, the following examples are the same) and the ratio of zinc oxide dust is 0.2mL / g. After mixing, ultrasonic oxidation leaching was carried out at 200W ultrasonic power and 19.5KHz ultrasonic frequency. The leaching reaction was carried out at a temperature of 90°C and a stirring speed of 400rpm for 60 minutes. After the reaction was completed, the leachate and leaching residue were obtained by liquid-solid separation. The leaching rates of zinc and germanium were 91.46% and 82.66% respectively.

Embodiment 2

[0039] Mix 30% hydrogen peroxide and sulfuric acid at a ratio of 0.62:1 to obtain a mixed leaching agent with a sulfuric acid concentration of 160g / L. Zinc oxide dust is mixed with the mixed leaching agent at a liquid-solid mass ratio of 6:1. The ratio is 0.49 mL / g. After mixing, ultrasonic oxidation leaching was carried out at 400W ultrasonic power and 25KHz ultrasonic frequency. The leaching reaction was carried out at a temperature of 90°C and a stirring speed of 200rpm for 60 minutes. After the reaction was completed, the leachate and leaching residue were obtained by liquid-solid separation. The leaching rates of zinc and germanium were 96.33% and 84.23% respectively.

Embodiment 3

[0042] Embodiment 3 (best embodiment)

[0043] Mix 30% hydrogen peroxide and sulfuric acid at a mass ratio of 0.52:1 to obtain a mixed leaching agent with a sulfuric acid concentration of 160g / L. Zinc oxide dust is mixed with the mixed leaching agent at a liquid-solid mass ratio of 7:1. The amount of hydrogen peroxide and zinc oxide The ratio of smoke to dust was 0.49 mL / g. After mixing, ultrasonic oxidation leaching was carried out at 200W ultrasonic power and 25KHZ ultrasonic frequency. The leaching reaction was carried out at a temperature of 60°C and a stirring speed of 400rpm for 60 minutes. After the reaction was completed, the leachate and leaching residue were obtained by liquid-solid separation. The leaching rates of zinc and germanium are 99.61% and 88.29% respectively.

[0044] In this example, the ratio of 30% hydrogen peroxide and sulfuric acid is 0.52:1, and the ratio of 30% hydrogen peroxide and zinc oxide dust is 0.49mL / g. The oxidation of hydrogen peroxide an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com