Silicon carbide MOSFET device with avalanche charge transition buffer layer and preparation method of silicon carbide MOSFET device

A buffer layer and silicon carbide technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve problems such as device failure and local temperature rise, so as to slow down local temperature rise, improve avalanche capability, and enhance avalanche reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

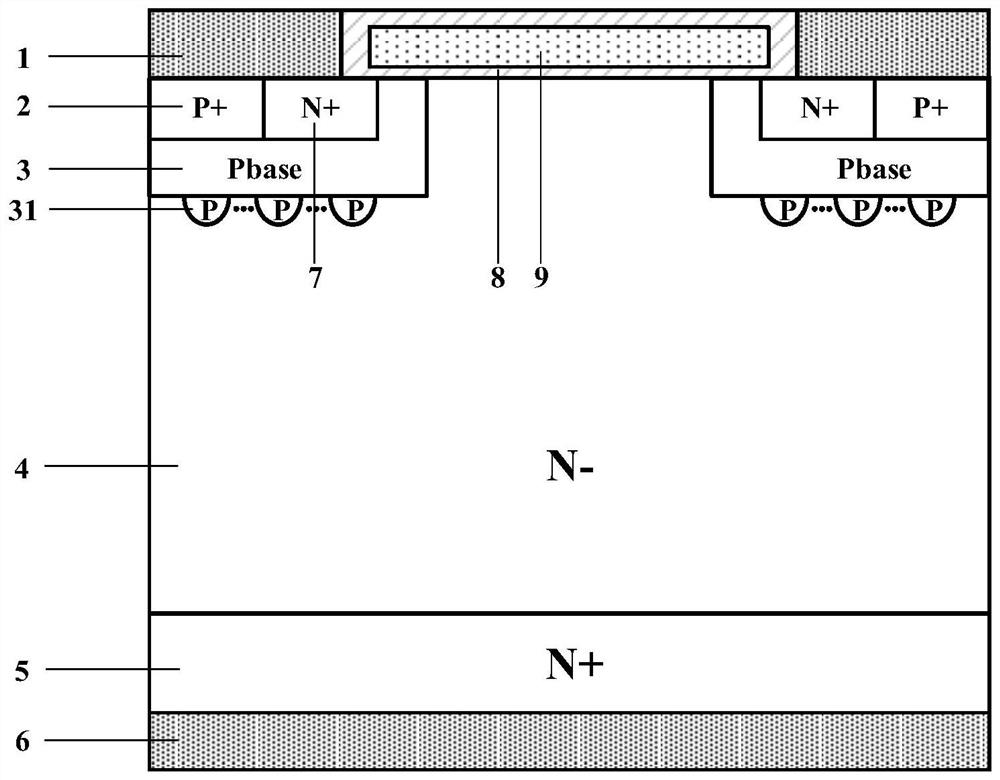

[0036] like figure 1 As shown, a silicon carbide MOSFET device with an avalanche charge transition buffer layer includes a drain metal 6, an N+ substrate 5 above the drain metal 6, and an N-drift region 4 above the N+ substrate 5; the N - There is a gate dielectric 8 and a polysilicon gate 9 in the middle of the upper part of the drift region 4; a P-type base region 3 is respectively arranged on the upper left and upper right inside the N-drift region 4, and the P-type base region 3 is below the P-type avalanche charge Transition buffer layer 31; the upper left P-type base region 3 includes the upper left P+ ohmic contact region 2, the N+ source region 7 on the right side of the P+ ohmic contact region 2; the upper right P-type base region 3 includes the upper right The P+ ohmic contact region 2, the N+ source region 7 on the left side of the P+ ohmic contact region 2; the source metal 1 above the N+ source region 7 and the P+ ohmic contact region 2; the part of the P-type bas...

Embodiment 2

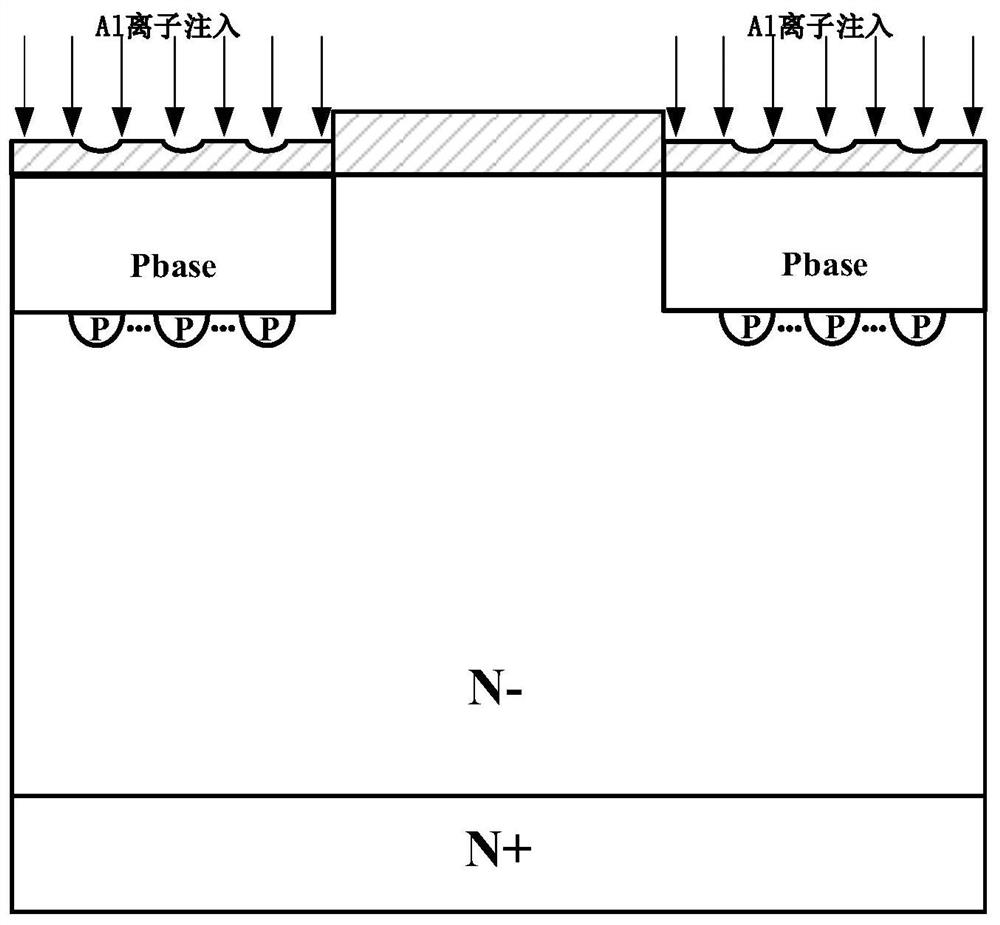

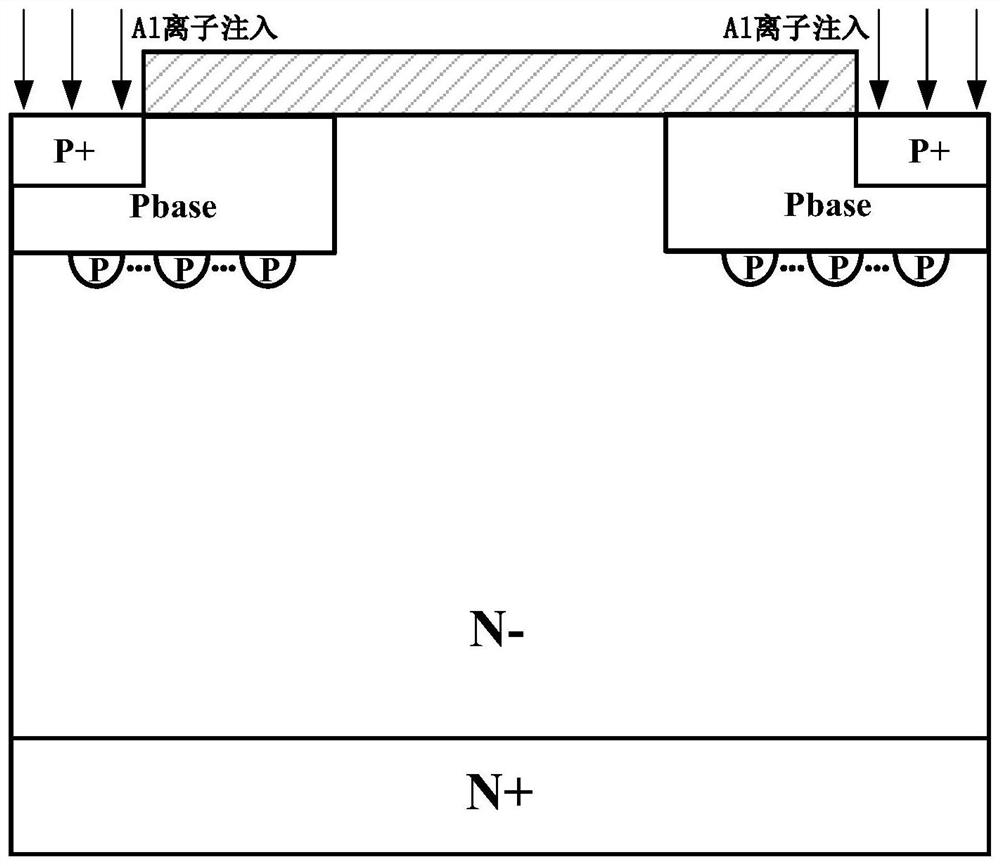

[0043] like Figure 2-Figure 9 As shown, the present embodiment provides a method for preparing the aforementioned silicon carbide MOSFET device having an avalanche charge transition buffer layer, comprising the following steps:

[0044] The first step: cleaning the epitaxial wafer, N-epitaxial with SiO 2 Implanting aluminum ions into the injection barrier layer to form a P-type avalanche charge transition buffer layer and a P-type base region;

[0045] Step 2: Implant aluminum ions to form P+ ohmic contact area;

[0046]Step 3: Implant nitrogen ions to form N+ source region and activate annealing;

[0047] The fourth step: wet oxygen oxidation to form a gate oxide layer;

[0048] Step 5: Deposit polysilicon, anneal after ion implantation and pattern the polysilicon;

[0049] Step 6: Deposit gate metal to form gate electrode;

[0050] Step 7: thermally grow the isolation oxide layer;

[0051] Step 8: Etching SiO 2 , depositing a source metal to form a source electrode; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com