Citrus dietary fiber with high water-holding capacity and expansibility and preparation method of citrus dietary fiber

A dietary fiber and water-holding technology, applied in the field of food additives, can solve the problems of insufficient scope of application, lack of controllability of biological methods, etc., and achieve the effects of reducing energy consumption, improving functional characteristics, and improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

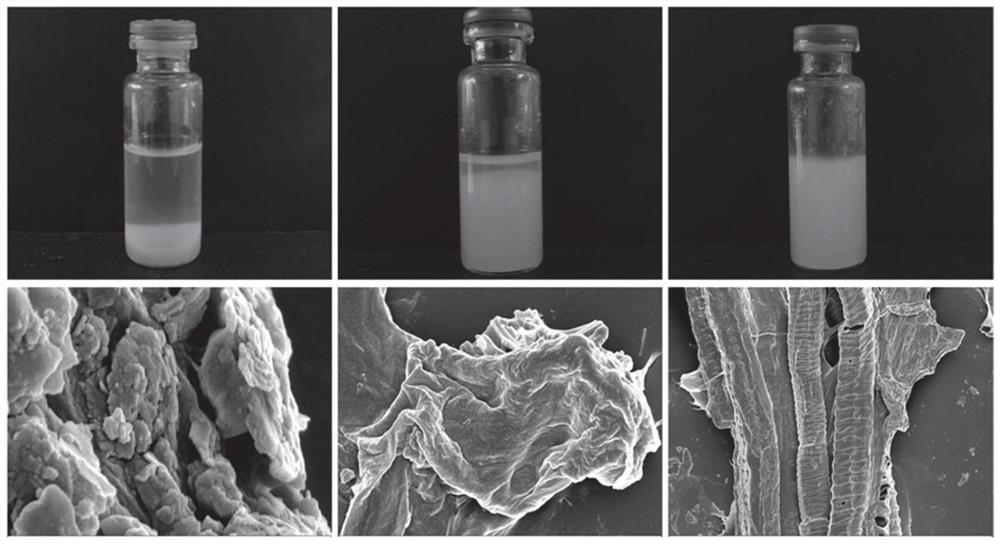

Image

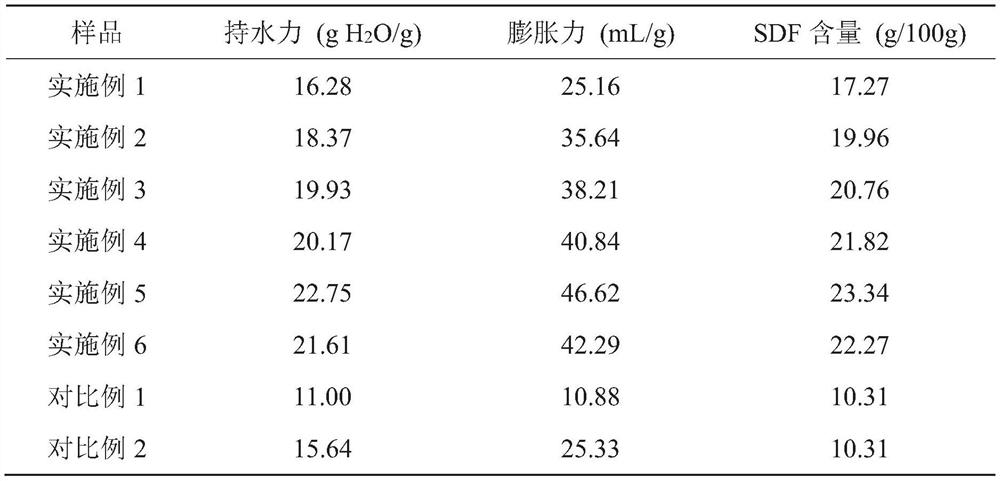

Examples

Embodiment 1

[0051] (1) Activate xylanase with citric acid-sodium hydrogen phosphate (CPBS) buffer solution with a pH of 3.0 in a constant temperature water bath at 30°C for 0.5h to obtain an enzyme activation solution, xylanase: orange dietary fiber The mass ratio of the slag is 0.30% (w / w); the tangerine dietary fiber slag and the enzyme activation solution are mixed according to 1g: 20mL, kept in a water bath at 30°C and stirred for 0.5h, and the citrus fiber suspension is placed Inactivate the enzyme in a water bath at 80°C for 10 minutes, cool to room temperature and add 1 volume of absolute ethanol, let stand for 0.5h, filter with a 200-mesh filter cloth, discard the liquid, collect the solids, and store at 50°C Dry to constant weight to obtain citrus fiber prepared by enzyme treatment.

[0052] Preparation of tangerine dietary fiber slag: add citrus peel to deionized water with a mass volume ratio of 1g: 20mL, adjust the pH of the citrus peel suspension to 1.5 with 1wt% nitric acid ...

Embodiment 2

[0055] Mix cellulase and xylanase in a mass ratio of 1:1, and activate the enzyme mixture with citric acid-disodium hydrogen phosphate (CPBS) buffer solution with a pH of 4.0 in a constant temperature water bath at 50°C for 0.5h , to obtain enzyme activation solution, enzyme mixture: the mass ratio of citrus dietary fiber slag is 0.45% (w / w); the citrus dietary fiber slag and enzyme activation solution are mixed according to 1g: 30mL, and are incubated and stirred in a water bath under the condition of 50°C After 1.5 hours, put the citrus fiber suspension in a water bath at 85°C for 15 minutes to inactivate the enzyme, cool to room temperature and add 4 times the volume of absolute ethanol, let it stand for 1 hour, filter it with a 300-mesh filter cloth, and discard the liquid , collect the solid matter, and dry it to constant weight under the condition of 60° C. to obtain citrus fiber prepared by enzyme treatment.

[0056] Preparation of citrus dietary fiber slag: add citrus ...

Embodiment 3

[0059] (1) Cellulase and citric acid-sodium hydrogen phosphate (CPBS) buffer solution with a pH of 5.0 were activated for 0.5h under the condition of a constant temperature water bath at 60°C to obtain an enzyme activation solution, cellulase: citrus dietary fiber residue The mass ratio is 0.15% (w / w); the citrus dietary fiber residue and the enzyme activation solution are mixed according to 1g: 40mL, kept in a water bath at 60°C and stirred for 1.5h. After the reaction, place the citrus fiber suspension at 85 Inactivate the enzyme in a water bath at ℃ for 20 minutes, cool to room temperature and add 4 times the volume of ethanol aqueous solution with a volume fraction of 95%, let it stand for 2 hours, filter with a 400-mesh filter cloth, discard the liquid, collect the solids, and store at 70 ℃ Drying to constant weight under conditions to obtain citrus dietary fiber based on enzyme treatment;

[0060] (2) Treat the citrus dietary fiber based on enzyme treatment with distille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com