Plasticizing system for PVDC products

A plasticizing system and product technology, which is applied in the field of food packaging materials, can solve problems such as excessive SMLSML values, achieve low esterification reaction temperature, and reduce preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

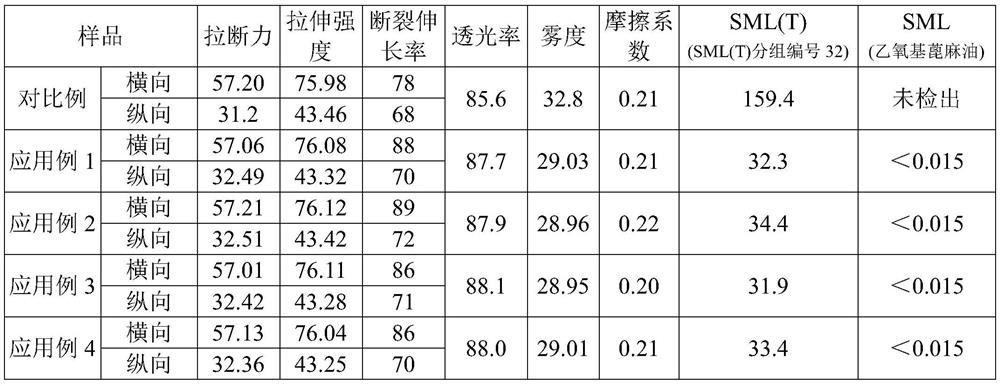

Examples

Embodiment 1

[0021] This example provides a plasticizing system for PVDC products, which consists of the following raw materials in parts by weight: 40 parts of diisononyl cyclohexane 1,2-dicarboxylate, 30 parts of dioctyl terephthalate , 15 parts of epoxidized soybean oil, 14 parts of acetyl tributyl citrate, and 1 part of ethoxylated castor oil.

[0022] Wherein, the preparation method of described dioctyl terephthalate comprises the steps:

[0023] (1) After mixing and stirring isocyanate and isopropyl titanate, add diethanolamine, mix and stir, and vacuum defoam at 18°C for 40 minutes to obtain a catalyst; the weight ratio of isocyanate and isopropyl titanate is 0.4:1, and the The weight ratio of isocyanate to the diethanolamine is 0.7:1;

[0024] (2) Take octanol and ethylene glycol and add them to the reaction kettle, then add terephthalic acid and catalyst, stir evenly, heat slowly, keep stirring during the heating process, the stirring speed is 35r / min, the temperature rises to ...

Embodiment 2

[0028] This example provides a plasticizing system for PVDC products, which consists of the following raw materials in parts by weight: 45 parts of diisononyl cyclohexane 1,2-dicarboxylate, 25 parts of dioctyl terephthalate , 18 parts of epoxy soybean oil, 10 parts of acetyl tributyl citrate, 2 parts of ethoxylated castor oil.

[0029] Wherein, the preparation method of described dioctyl terephthalate comprises the steps:

[0030] The preparation method of dioctyl terephthalate comprises the steps:

[0031] (1) After mixing and stirring isocyanate and isopropyl titanate, add diethanolamine, mix and stir, and vacuum defoam at 15°C for 50 minutes to obtain a catalyst; the weight ratio of isocyanate and isopropyl titanate is 0.3:1, and the The weight ratio of isocyanate to the diethanolamine is 0.8:1;

[0032] (2) Take octanol and ethylene glycol and add them to the reaction kettle, then add terephthalic acid and catalyst, stir evenly, heat slowly, keep stirring during the heat...

Embodiment 3

[0036] This example provides a plasticizing system for PVDC products, which consists of the following raw materials in parts by weight: 40 parts of diisononyl cyclohexane 1,2-dicarboxylate, 35 parts of dioctyl terephthalate , 12 parts of epoxidized soybean oil, 12 parts of acetyl tributyl citrate, 1 part of ethoxylated castor oil.

[0037] Wherein, the solubilizer is ethoxylated castor oil.

[0038] Wherein, the preparation method of described dioctyl terephthalate comprises the steps:

[0039] The preparation method of dioctyl terephthalate comprises the steps:

[0040] (1) After mixing and stirring isocyanate and isopropyl titanate, add diethanolamine, mix and stir, and vacuum defoam at 20°C for 30 minutes to obtain a catalyst; the weight ratio of isocyanate and isopropyl titanate is 0.5:1, and the The weight ratio of isocyanate to the diethanolamine is 0.6:1;

[0041] (2) Take octanol and ethylene glycol and add them to the reaction kettle, then add terephthalic acid and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com