3D laser photosensitive printing solder resist ink for integrated circuit and preparation method thereof

An integrated circuit and photosensitive technology, which is applied in the field of 3D laser photosensitive printing solder resist ink and its preparation, can solve the problems of aggravated processing, foaming, abnormal edges of solder resist graphics, etc., and achieve the improvement of glass transition temperature, reduction of VOC content, Effect of improving solder resist performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0037] Preparation examples 1-5 provide a maleic anhydride-modified polyimide photosensitive oligomer, and preparation example 1 is taken as an example below for illustration.

[0038] The maleic anhydride modified polyimide photosensitive oligomer that preparation example 1 provides, its preparation steps are:

[0039] (1) Mix 198g (0.8mol) diaminodiphenyl sulfone (CAS No. 80-08-0) and 40g (0.2mol) 4,4-diaminodiphenyl ether (CAS No. 101-80-4) Then add 10L of N-methylpyrrolidone, stir at 600rpm, add 229g (1.05mol) of pyromellitic anhydride under stirring, and react at 25°C for 3h to obtain reaction solution 1;

[0040] (2) Add dropwise 0.5mL isoquinoline and 2mL toluene to the reaction solution 1, N 2 Under the atmosphere, the temperature was raised to 160°C, and after the azeotrope of toluene and water was removed by distillation, the reaction was carried out at 160°C for 3 hours to obtain the reaction solution 2;

[0041] (3) Cool the reaction solution 2 to 50°C, add 9.8g ...

Embodiment 1

[0047] Embodiments 1-18 provide a 3D laser photosensitive printing solder resist ink for integrated circuits, which will be described below by taking Embodiment 1 as an example.

[0048] The preparation steps of the 3D laser photosensitive printing solder resist ink for integrated circuits provided in Example 1 are:

[0049] Mix 5g of ethyleneoxy acrylate and 10g of polycyclic acrylate, stir evenly at a stirring speed of 500rpm, then add 1g of sensitizer, mix, continue to stir evenly at a stirring speed of 500rpm, then add 20g of maleic anhydride to modify Polyimide photosensitive oligomer, stirred at a stirring speed of 800rpm to completely dissolve the maleic anhydride-modified polyimide photosensitive oligomer, then add 1g of photoinitiator, stir evenly, and finally add 0.1g of interface agent and 0.1g of fluorescent recognition agent, stirred evenly at a stirring speed of 500rpm, then allowed to stand for 30min, filtered with a 1 micron filter element, and the filtrate was...

Embodiment 2-5

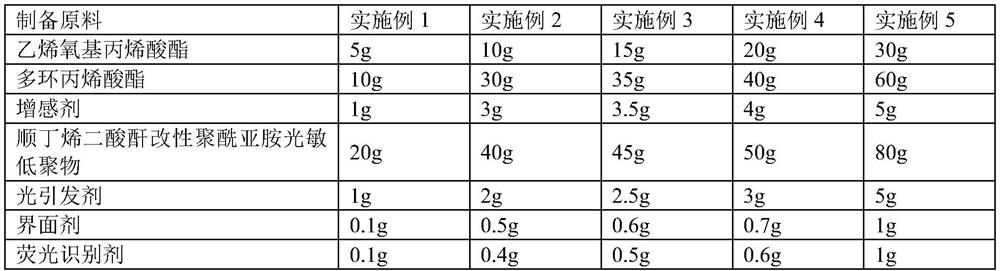

[0057] Examples 2-5 are the same as Example 1, except that the quality of the raw materials used for the preparation of the 3D laser photosensitive printing solder resist ink for integrated circuits is different, see Table 2 for details.

[0058] Table 2 embodiment 1-5 prepares the quality of raw material

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com