Composite nano antibacterial air filtering membrane

An air filtration and composite technology, applied in the direction of dispersed particle filtration, membrane, membrane technology, etc., can solve the problems that the filter membrane cannot be reused, reduces air permeability, and does not have antibacterial properties, so as to improve resource utilization, save costs, High filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

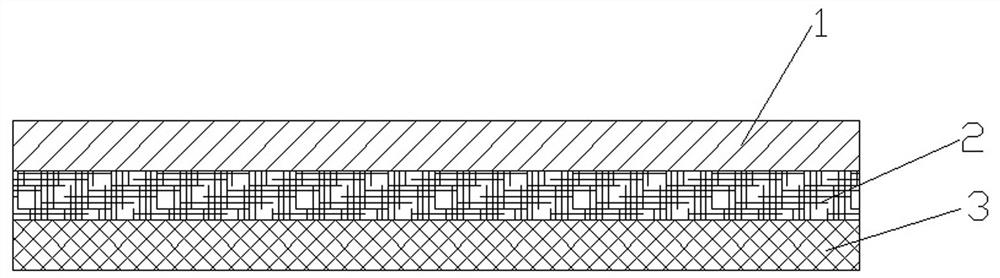

[0017] Embodiment 1: A kind of composite nano antibacterial air filter membrane, see figure 1 , including an aggregate base layer, a sticky spray layer, and a nanofiber film layer arranged in sequence. The aggregate base layer is made of impregnated wood pulp paper or polyester non-woven fabric, and the sticky spray layer is made of polyolefin materials, which are sprayed on the aggregate base layer. The nanofiber film layer is thermally bonded with the aggregate base layer through the sticky spray layer; the nanofiber film layer is a three-dimensional network structure composed of superfine fibers with a diameter of 300~500nm made of polymer materials by electrospinning process ; An antibacterial agent is added to the electrospinning solution used to prepare the nanofiber film layer, and the antibacterial agent is added to the electrospinning solution at a ratio of 0.1% to 1%.

[0018] Wherein, the nanofiber film layer is made of polyvinylidene fluoride or polyacrylonitrile p...

Embodiment 2

[0019] Embodiment 2: The preparation process of a kind of composite nano-antibacterial air filter membrane: first polyolefin material is sprayed on the surface of the aggregate base to form a sticky spray layer, and then the nanofiber film is covered on the sticky spray layer, passed through heat The nanofiber membrane and the aggregate base are bonded together by pressure to obtain the finished product of the composite nanometer antibacterial air filter membrane.

[0020] The composite nano-antibacterial air filter membrane in the present invention adopts glue-soaked wood pulp paper or polyester non-woven fabric as the aggregate base layer to support the entire filter membrane. By sticking and spraying polyolefin materials on the aggregate base layer, The sticky spray layer is formed to play a bonding role, and then the nanofiber film made by electrospinning is covered on the sticky spray layer, and the nanofiber film and the aggregate base layer are combined through hot-press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com